Magnetic Prussian blue carbon nano composite material and manufacturing method and application thereof

A nano-carbon material, Prussian blue technology, applied in the direction of inorganic material magnetism, chemical instruments and methods, alkali metal compounds, etc., can solve the problems of uneven shape, shedding, and low content of Prussian blue layer of magnetic composite materials, and the method is simple The effect of rapidity, good dispersion, and good magnetic separation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

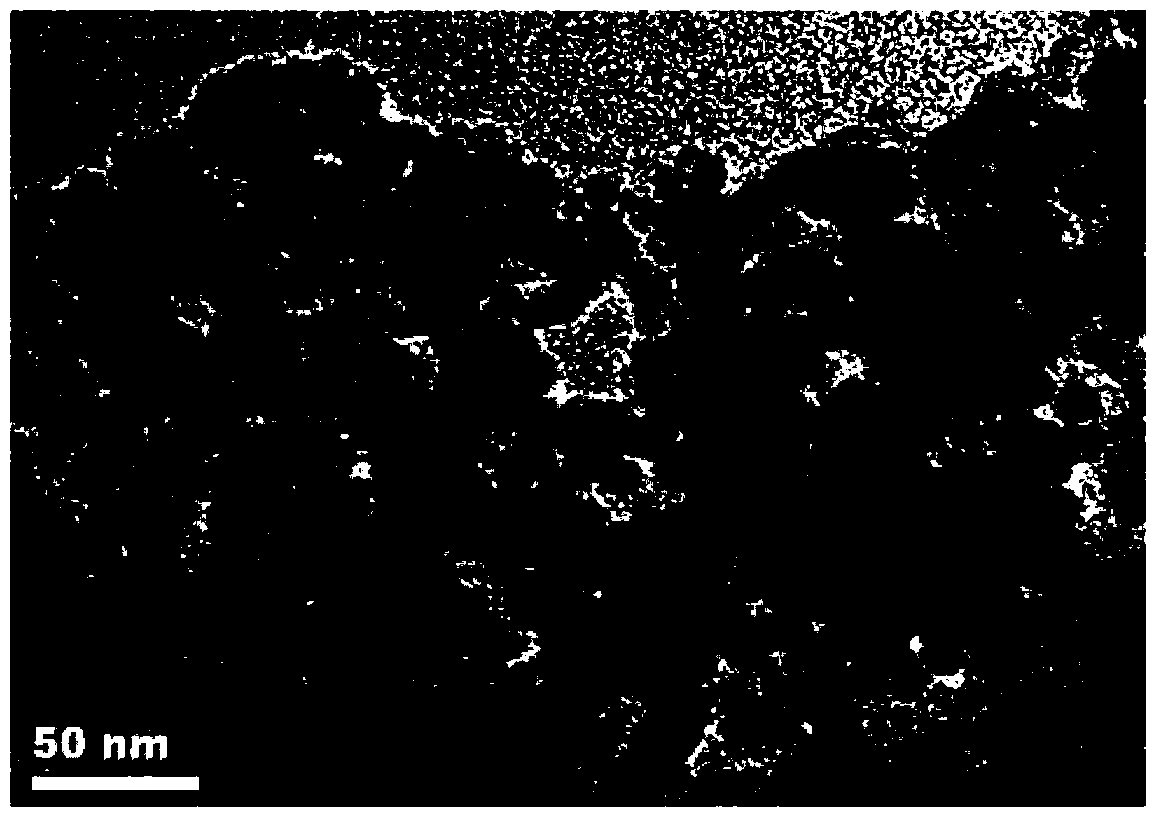

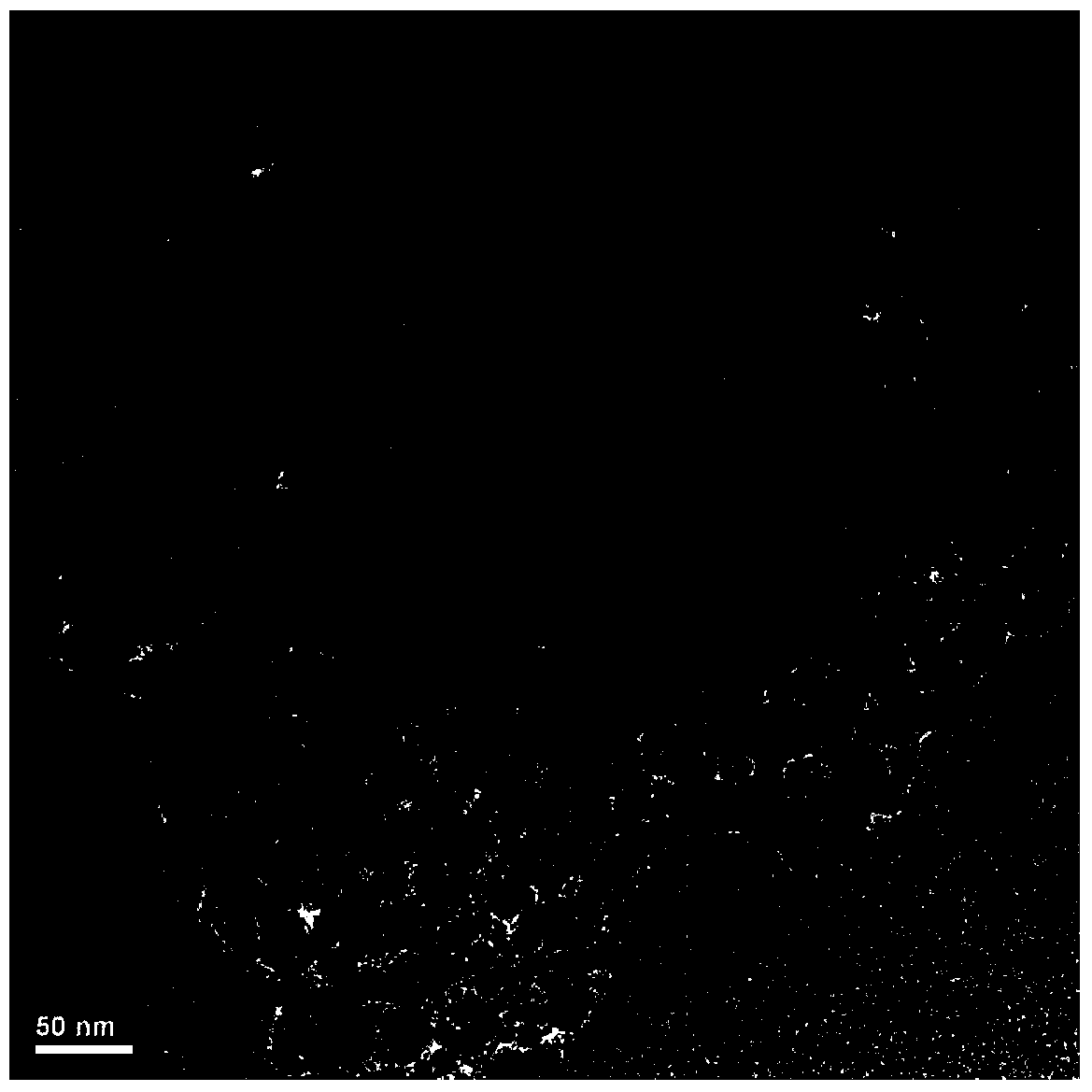

[0032] Embodiment 1: The magnetic Prussian blue nano-carbon composite material of this embodiment is made of nano-carbon materials, magnetic inorganic nanoparticles and Prussian blue, wherein the mass percentage of carbon nano-materials is 1-5%, The mass percentage of the magnetic inorganic nanoparticles is 35-40%, and the mass percentage of the Prussian blue is 55-60%.

specific Embodiment approach 2

[0033] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the mass percentage of carbon nanomaterials is 1.6%, the mass percentage of magnetic inorganic nanoparticles is 39.0%, and the mass percentage of Prussian blue is 59.4%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the nano-carbon material is graphene oxide or carbon nanotubes. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com