Method for preparing lithium-sulfur battery positive pole material

A positive electrode material, lithium-sulfur battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of difficult utilization of active materials, reduce battery life, and restrict commercial applications, etc., to achieve good cycle stability, inhibit Effect of agglomeration and improvement of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

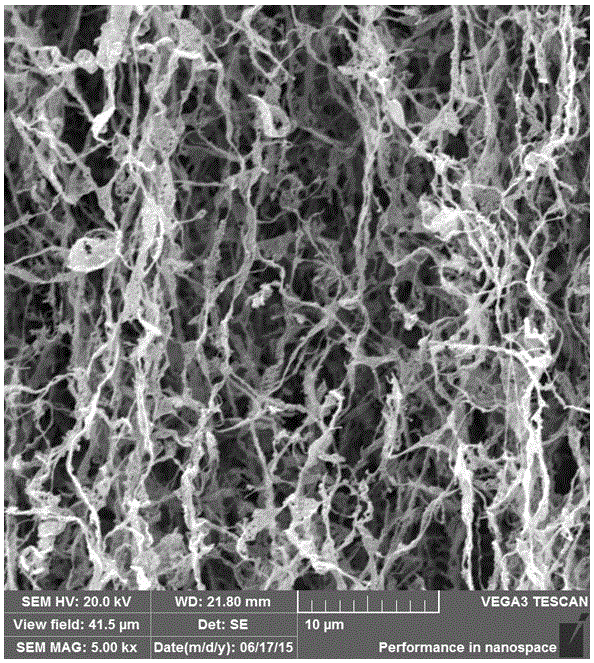

Image

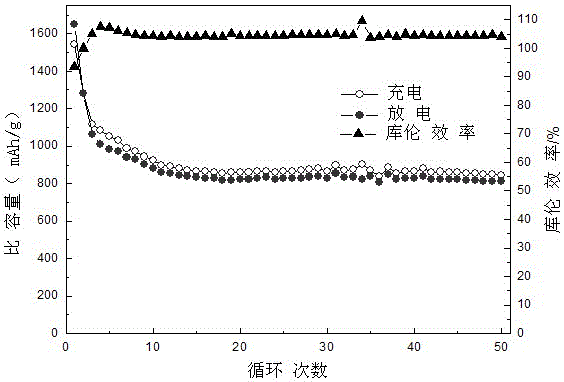

Examples

Embodiment 1

[0038] 1), the preparation of graphite oxide:

[0039] Add 39mL of concentrated sulfuric acid (98%) into a three-necked flask, then weigh 2.5g of potassium persulfate and 2.5g of phosphorus pentoxide and add them to the three-necked flask successively, mix well; then add 5g of natural flake graphite powder (325 mesh), Then place it in a constant temperature water bath and react for 6 hours under stirring at 80°C; slowly pour the reactant into a beaker filled with 700ml of deionized water for dilution, transfer the diluted liquid to a Buchner funnel for filtration, and wash until the filtrate into neutral. The obtained filter cake was dried under vacuum at 100° C. for 10 h, and the obtained solid matter was pre-oxidized graphite.

[0040] 2), the preparation of graphite oxide:

[0041]Weigh 2.5g of pre-oxidized graphite and 1.25g of sodium nitrate powder into a round-bottomed flask filled with 57.5mL of concentrated sulfuric acid (98%), slowly add 7.5g of potassium permangana...

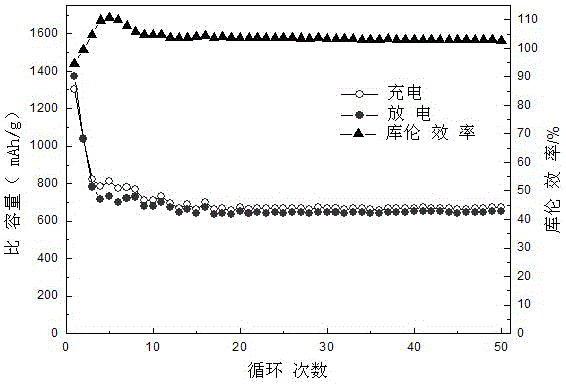

Embodiment 2

[0053] 1), the preparation of graphite oxide:

[0054] Mix 3g of natural flake graphite (200 mesh) with 2.5g of potassium persulfate and 2.5g of phosphorus pentoxide into a three-necked flask filled with 50mL of concentrated sulfuric acid (98%), mix well under magnetic stirring conditions, and then place at constant temperature In a water bath, react at 80°C for 6 hours; after the reaction, dilute with deionized water, then filter and wash with a Buchner funnel until the filtrate becomes neutral. The filter cake was dried under vacuum at 80° C. for 20 h, and the obtained solid matter was pre-oxidized graphite.

[0055] 2), the preparation of graphite oxide:

[0056] Weigh 2.5g of pre-oxidized graphite and 1.25g of sodium nitrate powder into a round-bottomed flask filled with 57.5mL of concentrated sulfuric acid (98%), slowly add 10g of potassium permanganate under ice-water bath conditions, and control the temperature of the reaction system below 20°C, after 3 hours of react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com