Preparation method for boron-nitrogen-co-doped three-dimensional structured positive electrode material of lithium-sulfur battery

A lithium-sulfur battery, three-dimensional structure technology, applied in battery electrodes, lithium storage batteries, structural parts, etc., can solve the problems of slowing electrochemical reaction kinetics, reducing the utilization rate of sulfur active materials, and restricting the development of lithium-sulfur batteries, etc. Achieve the effect of reducing the shuttle effect, conducive to electrical conductivity, and shortening the conduction distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

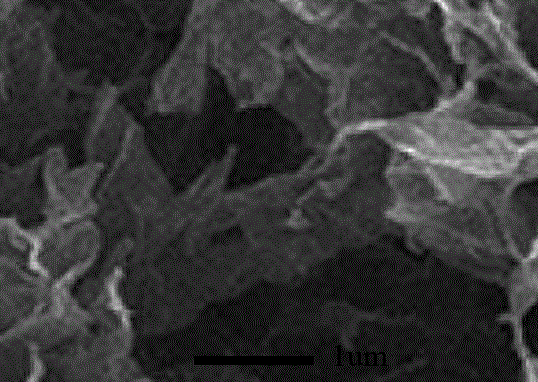

Image

Examples

Embodiment 1

[0019] (1) Add 10mg of graphite oxide into 10mL of water and sonicate for 10 minutes to form a 1g / L graphene oxide suspension;

[0020] (2) Add 100mL of ammonia water with a mass concentration of 25% to the graphene oxide suspension, then add 100mg of sodium borohydride, then transfer to a hydrothermal kettle for reaction, and react at 160°C for 6 hours. After the reaction is completed, wash with ethanol and water , and then freeze-dried to obtain three-dimensional boron-nitrogen co-doped graphene;

[0021] (3) Take 10 mg of the three-dimensional boron-nitrogen co-doped graphene obtained in (2) and 5 mg of Ketjen black and add it to 15 mL of N-methylpyrrolidone and ultrasonically form a 1 g / L suspension;

[0022] (4) Add 150mg of elemental sulfur to 15mL of N-methylpyrrolidone and sonicate at a certain 40°C until the elemental sulfur is completely dissolved to form a 10g / L suspension;

[0023] (5) Mix the two suspensions obtained in (4) and (3), stir evenly, then slowly add 9...

Embodiment 2

[0025] (1) Add 10 mg of graphite oxide to 1 mL of water and sonicate for 60 minutes to form a 10 g / L graphene oxide suspension;

[0026] (2) Add 500mL of ammonia water with a mass concentration of 25% to the graphene oxide suspension, then add 300mg of sodium borohydride, then transfer to a hydrothermal kettle for reaction, and react at 200°C for 1 hour. After the reaction is completed, wash with ethanol and water , and then freeze-dried to obtain three-dimensional boron-nitrogen co-doped graphene;

[0027] (3) Take 10 mg of the three-dimensional boron-nitrogen co-doped graphene obtained in (2) and 0.5 mg of Ketjen black and add it to 2.1 mL of N-methylpyrrolidone and ultrasonically form a 5 g / L suspension;

[0028] (4) Add 210mg of elemental sulfur to 14mL of N-methylpyrrolidone and sonicate at 50°C until the elemental sulfur is completely dissolved to form a 15g / L suspension;

[0029] (5) Mix the two suspensions obtained in (4) and (3), stir evenly, then slowly add 80.5 mL ...

Embodiment 3

[0031] (1) Add 10mg graphite oxide into 5mL water and sonicate for 30 minutes to form a 2g / L graphene oxide suspension;

[0032] (2) Add 200mL of ammonia water with a mass concentration of 25% to the graphene oxide suspension, then add 200mg of sodium borohydride, then transfer to a hydrothermal kettle for reaction, and react at 180°C for 3 hours. After the reaction is completed, wash with ethanol and water , and then freeze-dried to obtain three-dimensional boron-nitrogen co-doped graphene;

[0033] (3) Take 10 mg of three-dimensional boron-nitrogen co-doped graphene obtained in (2) and 1 mg of Ketjen black and add it to 5.5 mL of N-methylpyrrolidone and ultrasonically form a 2 g / L suspension;

[0034] (4) Add 132mg of elemental sulfur to 11mL of N-methylpyrrolidone and sonicate at 45°C until the elemental sulfur is completely dissolved to form a 12g / L suspension;

[0035] (5) Mix the two suspensions obtained in (4) and (3), stir evenly, then slowly add 66 mL of distilled wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com