Preparation method of three-dimensional sulfur-doped graphene/sulfur composite material electrode slice

A technology of sulfur-doped graphene and composite materials, which is applied in the field of preparation of lithium-sulfur battery cathode materials, can solve the problems of reducing the utilization rate of sulfur active materials, slow migration speed, and slow electrochemical reaction kinetics, achieving reduction The shuttle effect, the effect of improving the conductivity and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

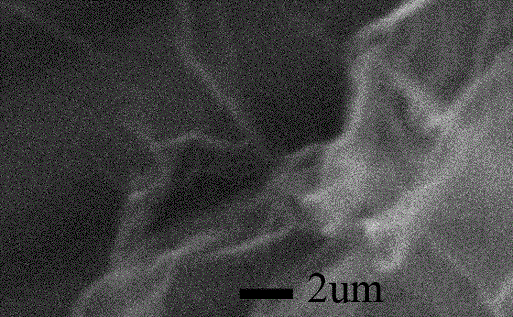

Image

Examples

Embodiment 1

[0018] (1) Mix and grind 1 g of graphite oxide and 0.8 g of benzene disulfide, and then put it into a nitrogen-protected muffle furnace at 800 ° C for 120 minutes to react. After the reaction, it is naturally cooled to room temperature to obtain sulfur-doped graphene.

[0019] (2) Add 1g of polyacrylonitrile, 0.7g of sulfur-doped graphene, and 0.3g of graphite oxide into 100mL of N-methylpyrrolidone, stir evenly and ultrasonically react for 30 minutes, then coat the mixed slurry on aluminum foil, Vacuum drying to obtain electrode sheets.

[0020] (3) Put the obtained electrode sheet into an inert gas-protected muffle furnace, slowly raise the temperature to 400°C at a rate of 3°C / min, react for 60 minutes, and cool naturally.

[0021] (4) Completely insert the electrode sheet obtained in (3) into 0.5mol / L Na 2 S 2 o 3 In the solution, stand still for 30 minutes, then slowly add 1mol / L hydrochloric acid dropwise to the solution until the solution pH=6.5, take out the electro...

Embodiment 2

[0023] (1) 1g of graphite oxide and 1.2g of benzene disulfide were mixed and ground, and then placed in a nitrogen-protected muffle furnace at 1200°C for 20 minutes to react. After the reaction, it was naturally cooled to room temperature to obtain sulfur-doped graphene.

[0024] (2) Add 1g of polyacrylonitrile, 0.9g of sulfur-doped graphene, and 0.1g of graphite oxide into 100mL of N-methylpyrrolidone, stir evenly and ultrasonically react for 120 minutes, then coat the mixed slurry on aluminum foil, Vacuum drying to obtain electrode sheets.

[0025] (3) Put the obtained electrode sheet into an inert gas-protected muffle furnace, slowly raise the temperature to 500°C at a rate of 5°C / min, react for 30 minutes, and cool naturally.

[0026] (4) Fully insert the electrode piece obtained in (3) into 2mol / L Na 2 S 2 o 3 In the solution, stand still for 60 minutes, then slowly add 1mol / L hydrochloric acid dropwise to the solution until the solution pH=7.5, take out the electrode ...

Embodiment 3

[0028] (1) Mix and grind 1g of graphite oxide and 1g of benzene disulfide, then put it in a nitrogen-protected muffle furnace at 900°C for 100 minutes, and cool it down to room temperature naturally after the reaction to obtain sulfur-doped graphene.

[0029] (2) Add 1g of polyacrylonitrile, 0.75g of sulfur-doped graphene, and 0.25g of graphite oxide into 100mL of N-methylpyrrolidone, stir evenly and ultrasonically react for 60 minutes, then coat the mixed slurry on aluminum foil, Vacuum drying to obtain electrode sheets.

[0030] (3) Put the obtained electrode sheet into an inert gas-protected muffle furnace, slowly raise the temperature to 450°C at a rate of 4°C / min, react for 45 minutes, and cool naturally.

[0031] (4) Fully insert the electrode piece obtained in (3) into 1mol / L Na 2 S 2 o 3 In the solution, stand still for 50 minutes, then slowly add 1mol / L hydrochloric acid dropwise to the solution until the pH of the solution is 7, take out the electrode sheet, and o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com