Positive electrode of lithium-sulfur battery using nitride/carbon nano tube as interlayer, battery and preparation method

A carbon nanotube, lithium-sulfur battery technology, applied in the field of electrochemistry, can solve the problems of harsh production conditions, battery capacity decay, complicated and cumbersome processes, etc., and achieves the effects of simple preparation, improved electrical conductivity, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

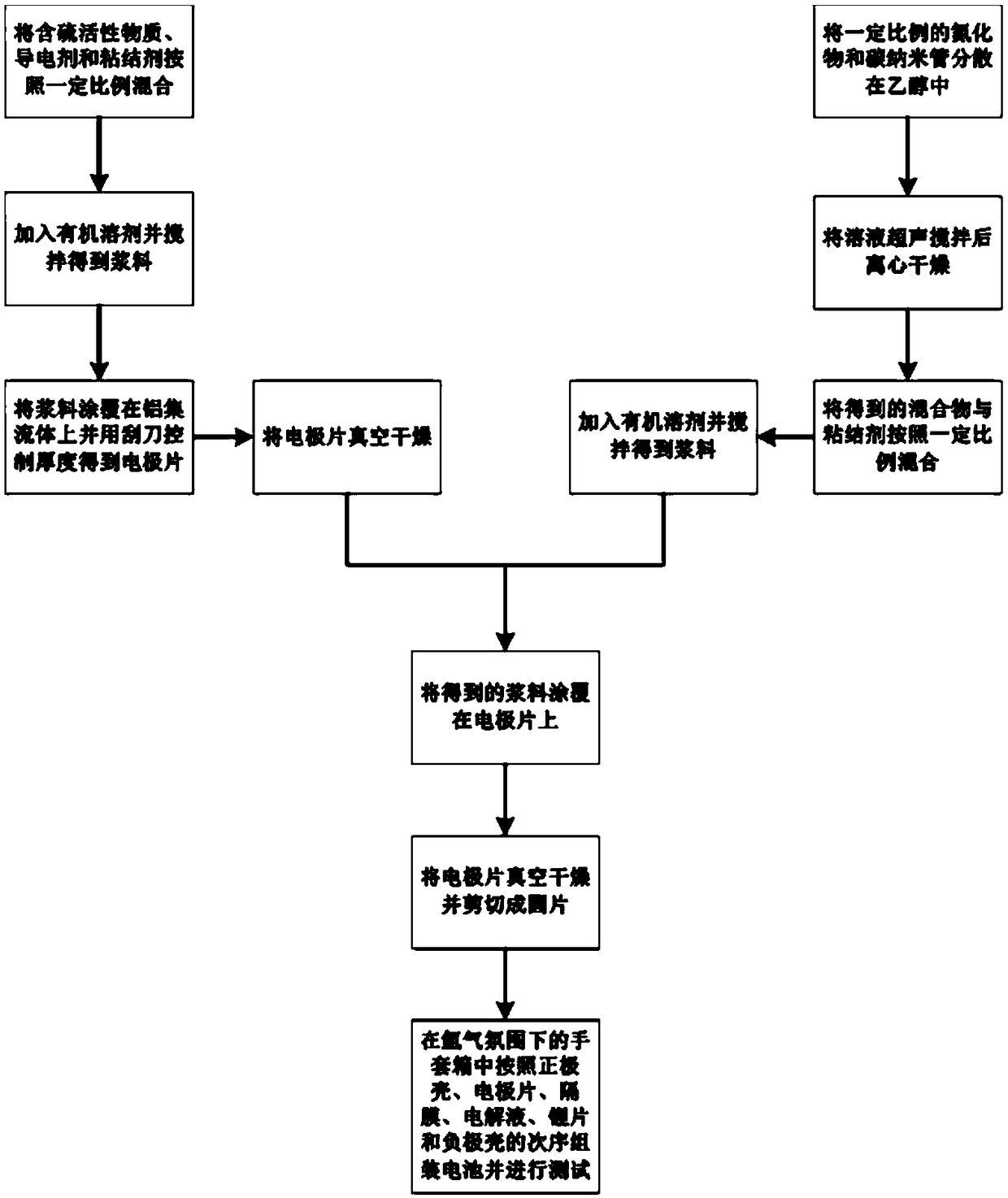

[0037] The preparation method of the nitride / carbon nanotube interlayer is: ultrasonically disperse the nitride and carbon nanotube in ethanol, and separate the nitride / carbon nanotube composite by centrifugation, wherein the mass fraction of the carbon nanotube is nitride / carbon nanotube 10% to 90% of the total mass of carbon nanotubes; mix the nitride / carbon nanotube compound and the binder according to the mass ratio (7-9): (1-3), add an organic solvent and stir after mixing The slurry is uniformly obtained, and the slurry is evenly coated on the positive electrode sheet, and the thickness of the slurry coated on the aluminum current collector is 100-400 μm. Vacuum drying at 40-70°C to obtain a nitride / carbon nanotube interlayer; wherein, the amount of the added organic solvent is 10-30 times the mass of the added sulfur-containing active material.

[0038] The conductive agent is one or more of conductive carbon black Ketjen Black, Super P, Super C65, acetylene black, grap...

Embodiment 1

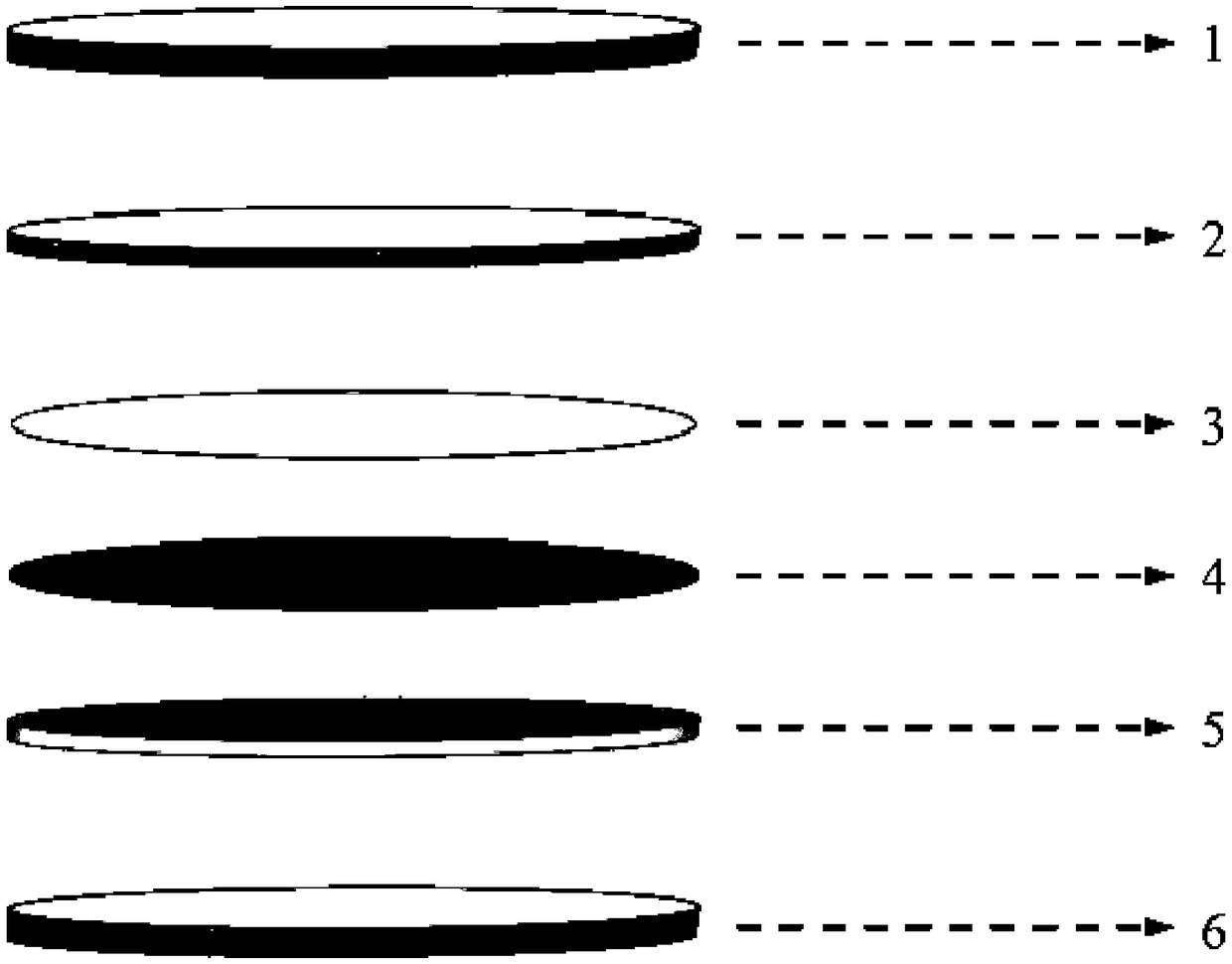

[0049] A lithium-sulfur battery with nitride / carbon nanotubes as the positive electrode separator, including a sulfur-containing active material positive electrode, a separator, an electrolyte, and a metal lithium negative electrode; a layer of nitride / carbon nanotubes is coated on the sulfur-containing active material positive electrode Composite compartment.

[0050] The preparation method of the positive electrode of the sulfur-containing active material is: conductive carbon black Ketjen black / sulfur compound (the mass fraction of sulfur in the conductive carbon black Ketjen black / sulfur compound is 50%) as the sulfur-containing active material, acetylene black as the conductive Agent and binder (PVDF) are mixed at a mass ratio of 8:1:1. During the mixing process, 3mL of organic solvent N-methylpyrrolidone is added, and stirred at a medium speed of 500r / min for 1h to obtain a slurry; then use an adjustable Scraper, set the coating conditions: the coating thickness is 350 μ...

Embodiment 2

[0064] Preparation method of sulfur-containing active material positive electrode:

[0065] Conductive carbon black Ketjen black / sulfur compound (the mass fraction of sulfur in the conductive carbon black Ketjen black / sulfur compound is 50%) is a sulfur-containing active material, acetylene black is a conductive agent, and the binder (PVDF) is based on mass Mix the materials at a ratio of 8:1:1, add 3mL of organic solvent N-methylpyrrolidone during the mixing process, and stir at a medium speed of 500r / min for 1h; then, use an adjustable scraper to set the coating conditions: the coating thickness is 350μm , the coating width is 400mm, the slurry is uniformly coated on the aluminum current collector, and the current collector is placed in a vacuum oven at 60°C for 24 hours to obtain a positive electrode material containing a sulfur active material.

[0066] Interlayer preparation method:

[0067] Lithium nitride / multi-walled carbon nanotubes (mass fraction of multi-walled car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com