Hollow carbon-sulfur positive electrode composite material coated with flaky manganese dioxide and preparation and application thereof

A technology of manganese dioxide and composite materials, applied in battery electrodes, electrical components, non-aqueous electrolyte storage batteries, etc., can solve problems such as poor capacity retention, complex reaction, low Coulombic efficiency, etc., and achieve uniform carbon sphere shape, Simple preparation process and controllable carbon layer thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

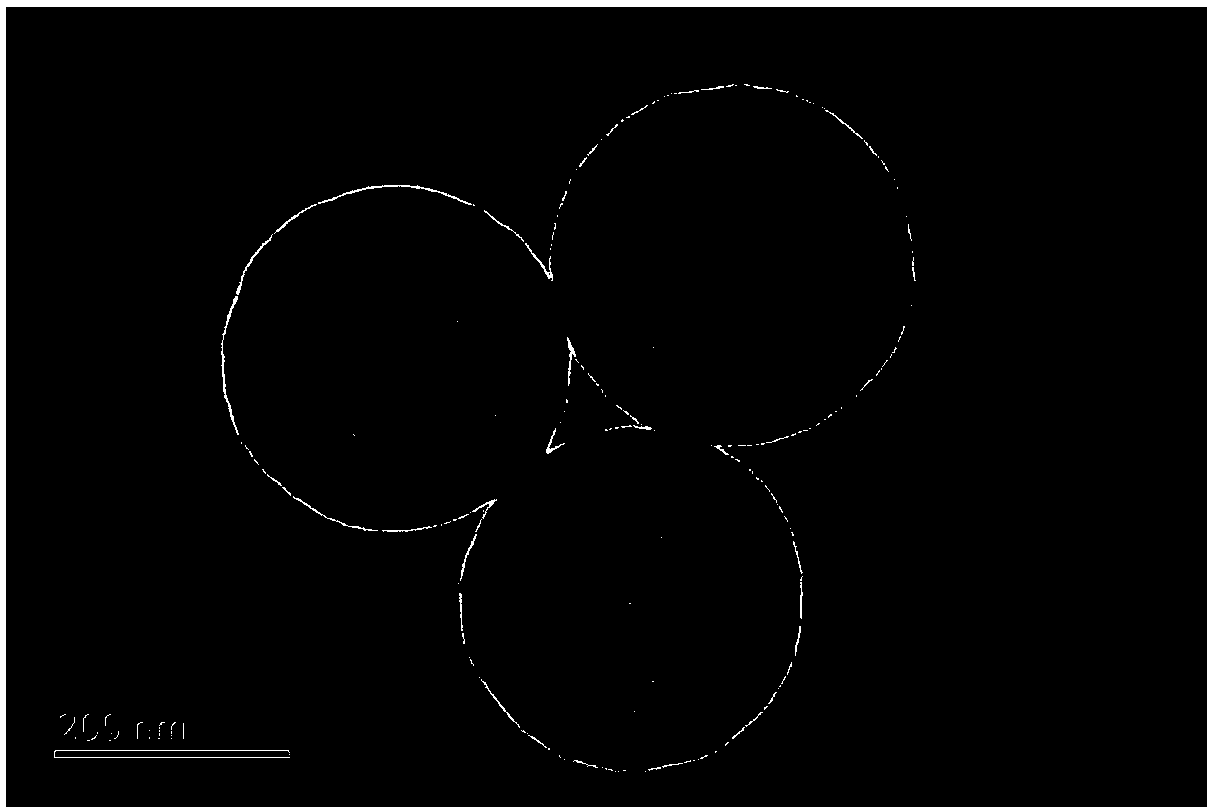

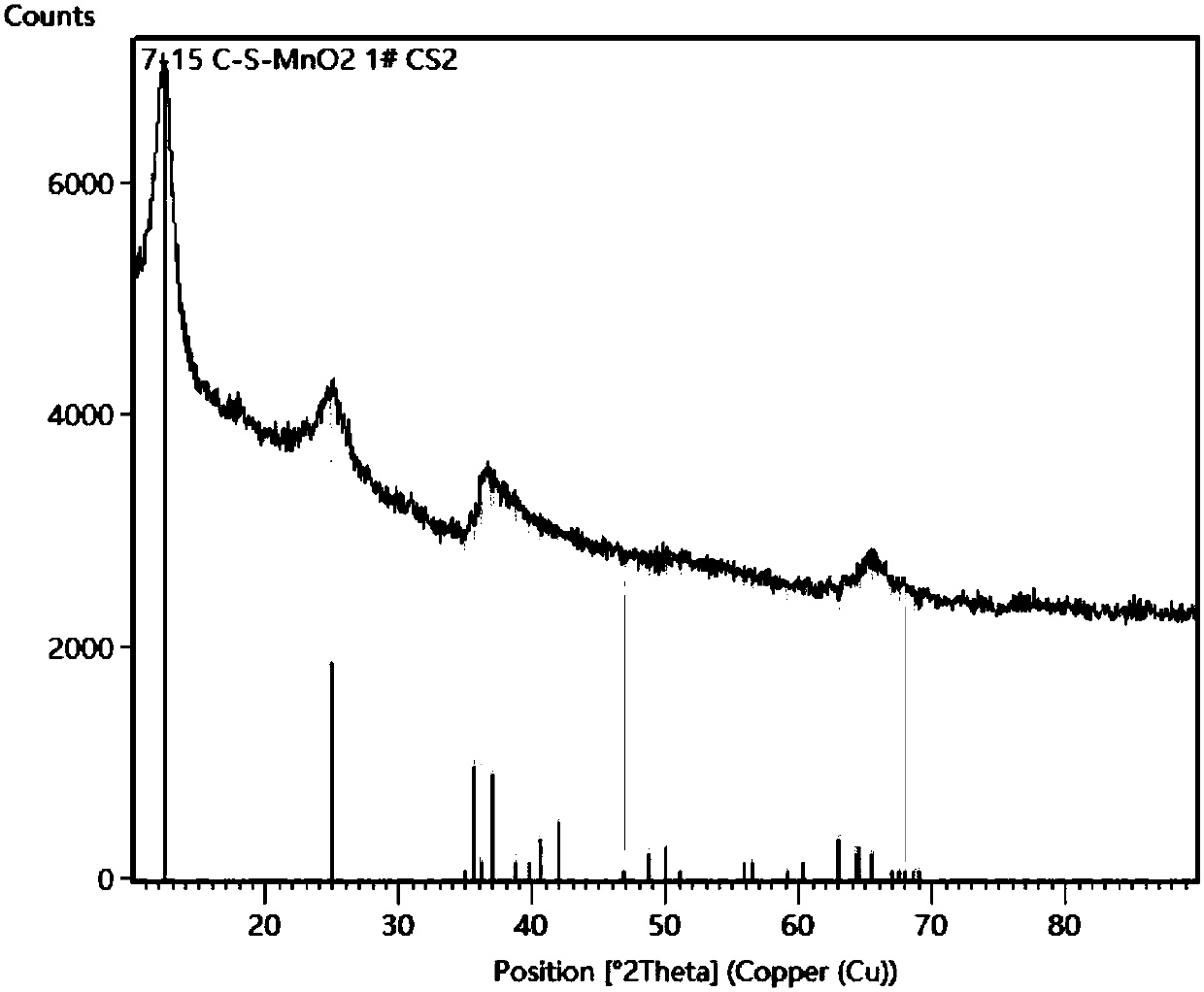

[0031] The steps of preparing the hollow carbon-sulfur composite material are the same as those of the comparative example. Take 0.1g of the carbon-sulfur composite material, sonicate it for 1 hour, disperse it in 80ml of deionized water, and add 20ml of 0.03mol / L KMnO 4 The solution was reacted in a water bath at 70° C. for 2 hours, centrifuged, washed, and dried to obtain a flaky manganese dioxide-coated hollow carbon-sulfur material. The coating of the subsequent pole piece and the assembly test of the battery are the same as the comparative example. The XRD powder diffraction pattern of the carbon composite material coated with manganese dioxide; image 3 Shown; transmission electron microscope picture is shown in Figure 4 shown.

[0032] Depend on figure 1 It can be seen that the particle size is 200+20nm, from which it can be seen that there are abundant microporous and mesopore structures distributed on the surface of hollow carbon spheres. The carbon layer and the...

Embodiment 2

[0036] The procedure for preparing the hollow carbon-sulfur composite material is the same as that of the comparative example. Take 0.1g of the carbon-sulfur composite material, sonicate it for 1 hour, disperse it in 80ml of deionized water, and add 20ml of 0.01mol / L KMnO 4 The solution was reacted in a water bath at 70° C. for 2 hours, centrifuged, washed, and dried to obtain a flaky manganese dioxide-coated hollow carbon-sulfur material. The coating of the subsequent pole piece and the assembly test of the battery are the same as the comparative example. XRD powder diffraction pattern of manganese dioxide-coated carbon composite materials; scanning electron microscope, transmission electron microscope test, battery specific capacity test, the results show that KMnO 4 Concentration decreases although the reduction of MnO in composites 2 content, but it also provides enough pathways for the migration of lithium ions, and the capacity performance of the battery is slightly low...

Embodiment 3

[0038] The procedure for preparing the hollow carbon-sulfur composite material is the same as that of the comparative example. Take 0.1g of the carbon-sulfur composite material, sonicate it for 1 hour, disperse it in 80ml of deionized water, and add 20ml of 0.1mol / L KMnO 4 The solution was reacted in a water bath at 70° C. for 2 hours, centrifuged, washed, and dried to obtain a flaky manganese dioxide-coated hollow carbon-sulfur material. The coating of the subsequent pole piece and the assembly test of the battery are the same as the comparative example. XRD powder diffraction pattern of manganese dioxide-coated carbon composite materials; scanning electron microscope, transmission electron microscope test, battery specific capacity test, the results show that KMnO 4 Concentration increase increases the MnO 2 Although the content of the pole piece is reduced, the capacity retention rate of the battery is improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Carbon layer thickness | aaaaa | aaaaa |

| Mesoporous | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com