Preparation method of lithium-sulfur battery composite separator

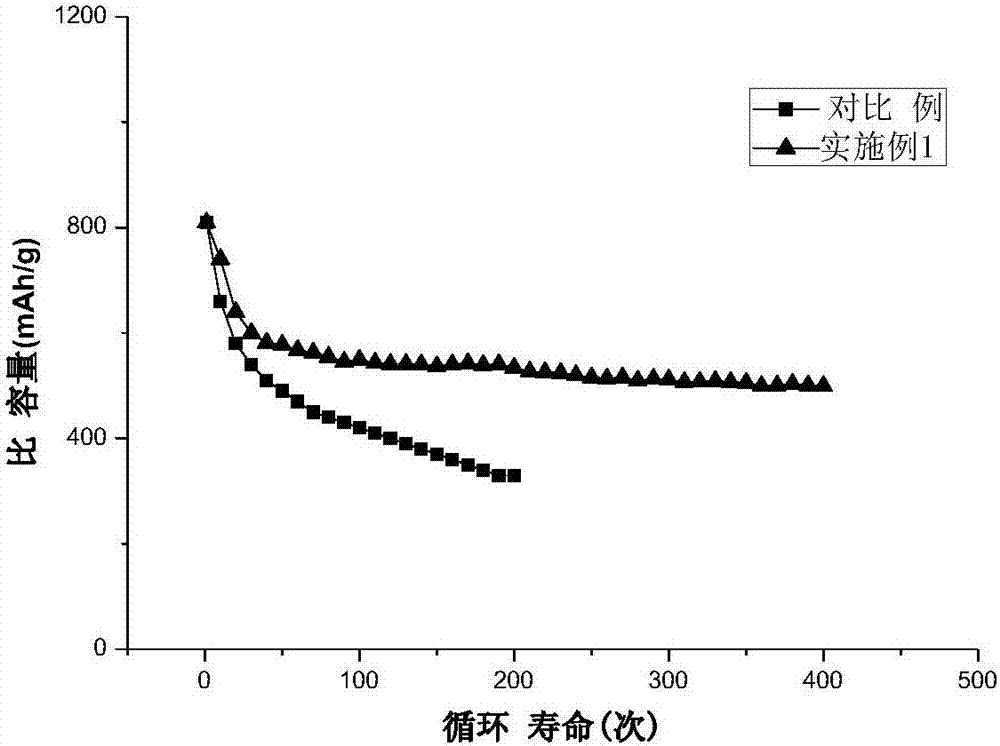

A composite diaphragm and lithium-sulfur battery technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of reducing the utilization rate of sulfur active materials, slow migration speed, and deteriorating the performance of lithium-sulfur batteries, so as to reduce the shuttle effect, life-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

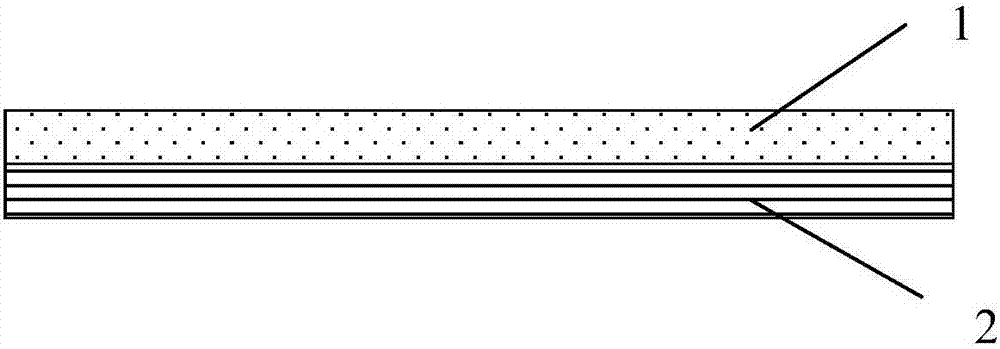

Image

Examples

Embodiment 1

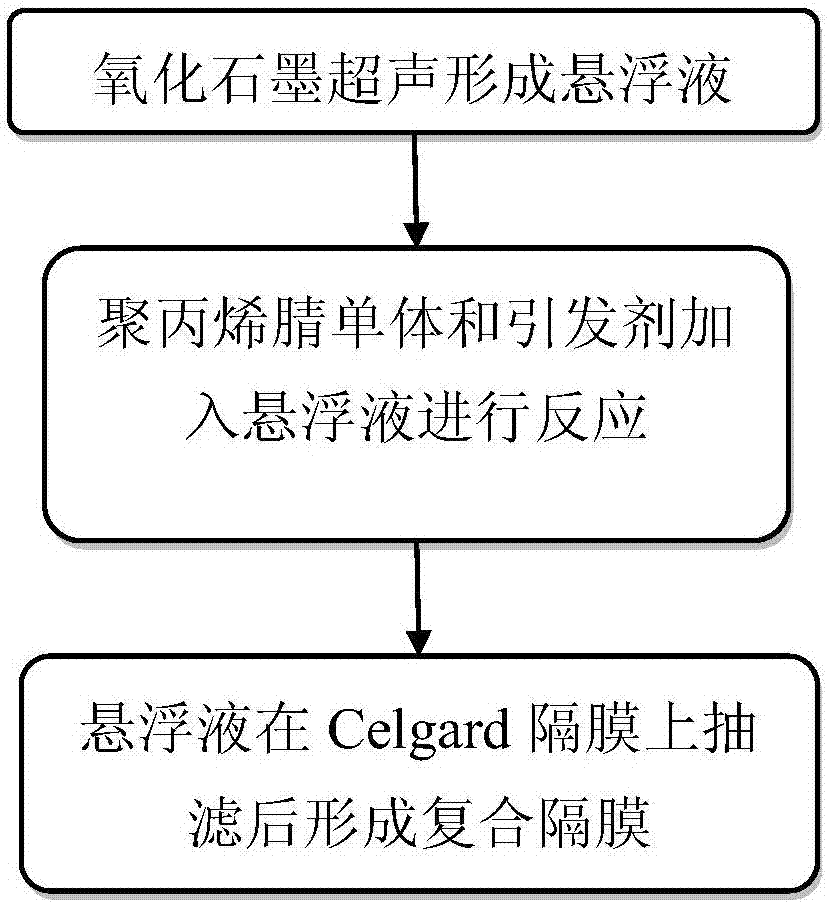

[0016] (1) Add 10g of graphite oxide to 10g of N-methylpyrrolidone and disperse by ultrasonic for 5 hours to form a suspension;

[0017] (2) Add 1g of polyacrylonitrile monomer to the above suspension, stir for 1 hour to disperse evenly, then add 0.01g of initiator azobisisobutyronitrile to the suspension, stir and react for 1 hour, after the reaction is complete, The suspension was poured into a suction filter bottle lined with a Celgard diaphragm and filter paper for suction filtration, and the filter paper was torn off after drying to obtain a lithium-sulfur battery composite diaphragm.

Embodiment 2

[0019] (1) Add 10g of graphite oxide into 100g of dimethyl sulfoxide and disperse by ultrasonication for 0.5 hours to form a suspension;

[0020] (2) Add 5g of polyacrylonitrile monomer to the above suspension, stir for 5 hours to disperse evenly, then add 0.15g of initiator dibenzoyl peroxide to the suspension, stir and react for 5 hours, after the reaction is complete, The suspension was poured into a suction filter bottle lined with a Celgard diaphragm and filter paper for suction filtration, and the filter paper was torn off after drying to obtain a lithium-sulfur battery composite diaphragm.

Embodiment 3

[0022] (1) Add 10g of graphite oxide into 50g of N,N-dimethylformamide, disperse by ultrasonic for 3 hours to form a suspension;

[0023] (2) Add 3g of polyacrylonitrile monomer to the above suspension, stir for 3 hours to disperse evenly, then add 0.09g of initiator ammonium persulfate to the suspension, stir and react for 3 hours, after the reaction is complete, dissolve the suspension Pour it into a suction filter bottle lined with a Celgard diaphragm and filter paper for suction filtration, and tear off the filter paper after drying to obtain a lithium-sulfur battery composite diaphragm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com