Individual packages of absorbent articles, packaging sheet and process for production of packaging sheet

A manufacturing method and packaging technology, which is applied to the packaging of fragile items, packaging, absorbent pads, etc., can solve the problems of scattered texture, damaged airtightness, and dust mixed in, achieve soft touch and appearance, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

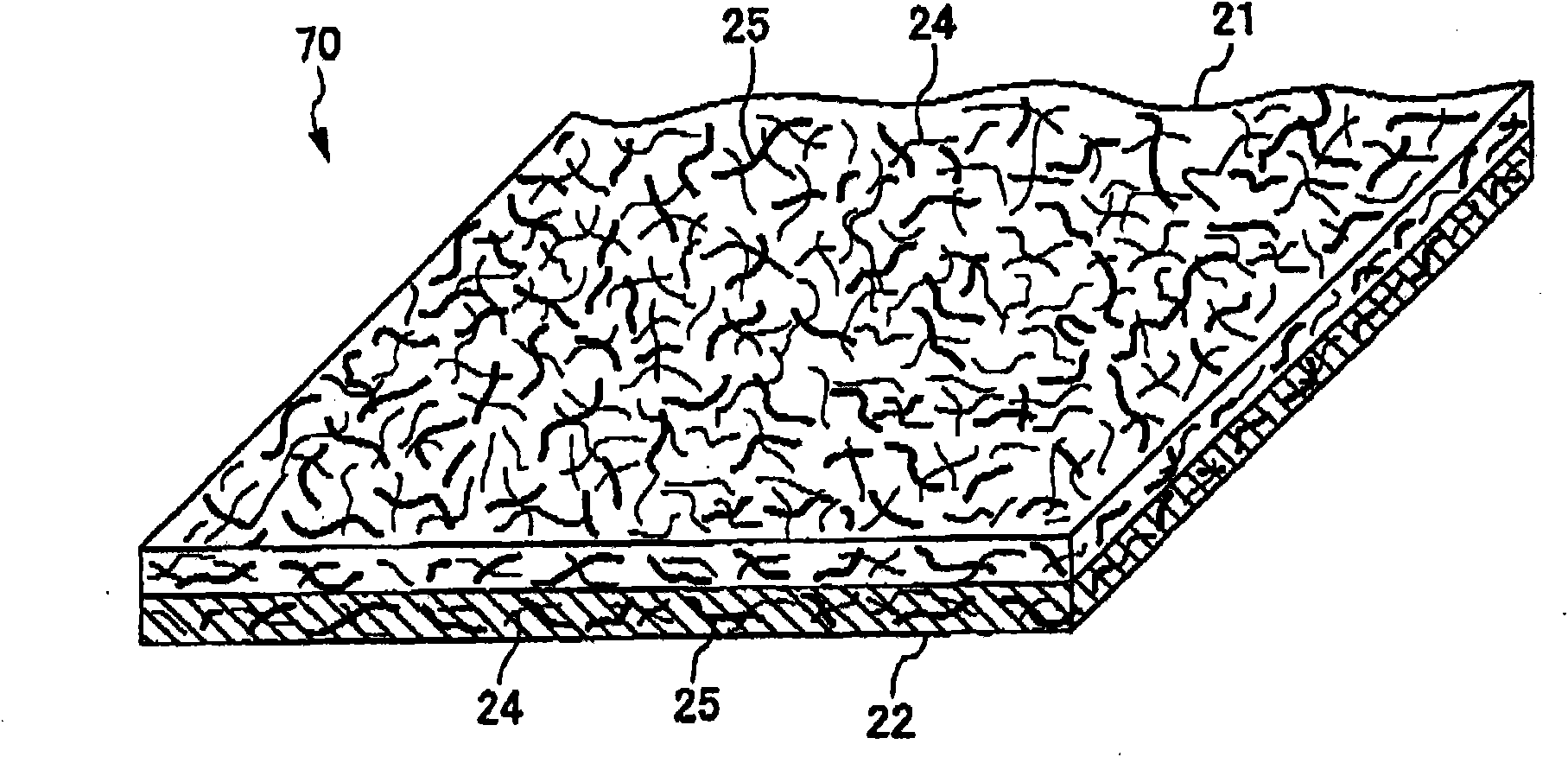

[0043] figure 1 It is a schematic diagram showing a first embodiment of the packaging sheet of the present invention, and the double-layered packaging sheet 70 has a laminated structure of the first fiber layer 21 and the second fiber layer 22 . The first fiber layer 21 contains pulp fibers 24 and chemical fibers 25 in an interwoven state. As will be described later, these two fibers are formed by interweaving through high-pressure water jet processing. The pulp fibers 24 and the chemical fibers 25 are rearranged by interweaving by high-pressure water jet treatment, and the fiber density of the entire first fiber layer 21 becomes coarse, so the appearance is good and the flexibility is good.

[0044] By making the 1st fiber layer 21 contain the pulp fiber 24, the intensity|strength of the 1st fiber layer 21 can be improved.

[0045] The pulp fibers 24 used in the first fiber layer 21 can be, for example, LBKP, NBKP, wood pulp, non-wood pulp such as hemp and cotton, regenerated ...

no. 2 approach

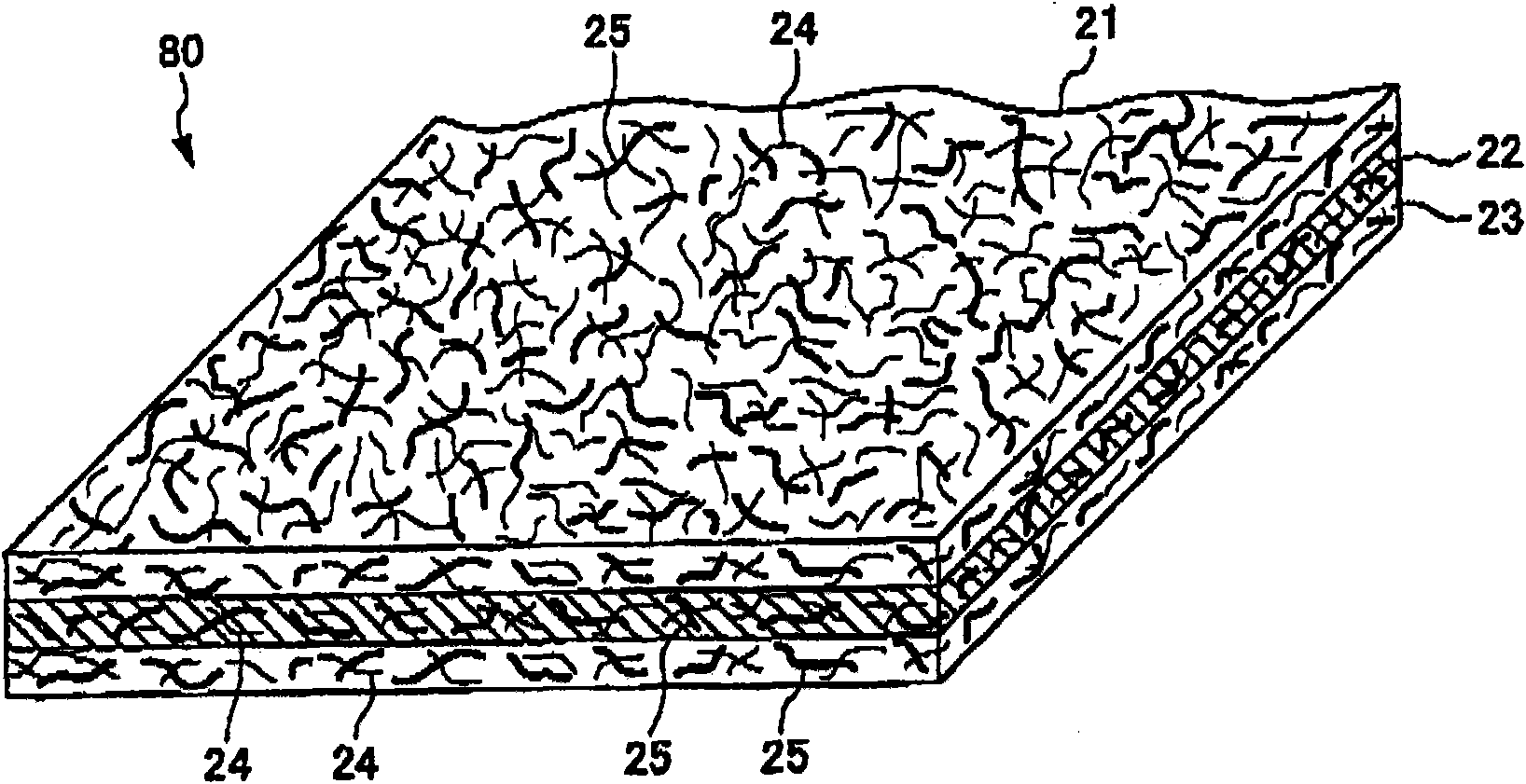

[0074] Such as figure 2 As shown, the second embodiment of the packaging sheet of the present invention is the same as the first embodiment except that the third fiber layer 23 is laminated on the second fiber layer 22 on the side opposite to the first fiber layer 21 . The third fiber layer 23 is the same as the first fiber layer 21, and contains interwoven pulp fibers 24 and chemical fibers 25, which are formed by interweaving through high-pressure water jet processing. The pulp fibers 24 and the chemical fibers 25 are rearranged by interweaving by high-pressure water jet treatment, and the fiber density of the entire third fiber layer 23 becomes coarse, so the appearance is good and the flexibility is good.

[0075] By making the third fiber layer 23 contain the pulp fiber 24, the strength of the third fiber layer 23 can be increased.

[0076] The pulp fibers 24 used in the third fiber layer 23 can be, for example, LBKP, NBKP, wood pulp, non-wood pulp such as hemp and cott...

Embodiment 1

[0157] In addition to Example 1, from Example 2 to Example 6, the packaging sheets to which dyes or sizing agents were added within the range not to impair the hydrolyzability were also produced, and the contents of pulp fibers 24 and chemical fibers 25 were changed. The same test and measurement as in Example 1 were carried out for packaging sheets such as square meter weight. In addition, the size and shape of Example 2 to Example 6 are the same as those of Example 1.

[0158] [Manufacture of sheets for three-layer laminated packaging]

[0159] (manufacturing of the first fiber layer)

[0160] As the pulp fiber 24, NBKP (CSF720cc) and synthetic pulp (SWP E-400 manufactured by Mitsui Chemicals Co., Ltd.) were used in combination.

[0161] As the chemical fiber 25, a viscose fiber (Corona produced by Daiwa Spun Viscose Co., Ltd.) with a fineness of 1.1 dtex and an average fiber length of 7 mm was used.

[0162] The content of pulp fiber 24 and chemical fiber 25 is 60% by ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com