Hydrolytically degradable poss-peg hybrid hydrogel and its preparation method and use

A hydrogel, PEG-SH technology, applied in biochemical equipment and methods, pharmaceutical formulations, cell encapsulation, etc., can solve the problems of reducing the activity of biological cells, limiting the application of POSS hybrid hydrogels, etc., to improve survival ability, non-toxic hydrolysis, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

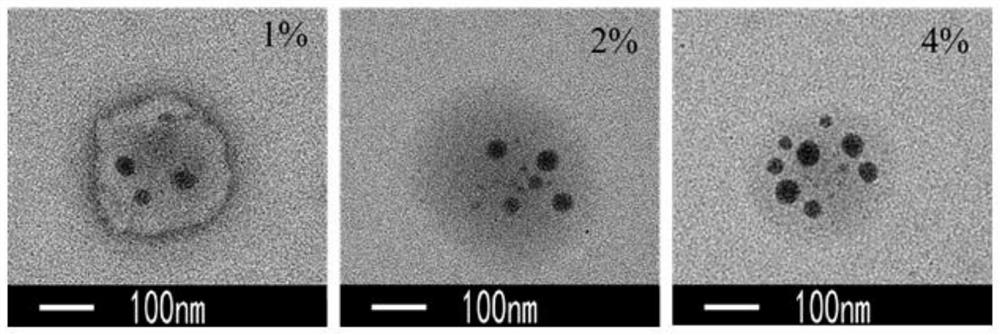

[0043] Preparation of POSS-PEG hybrid hydrogel

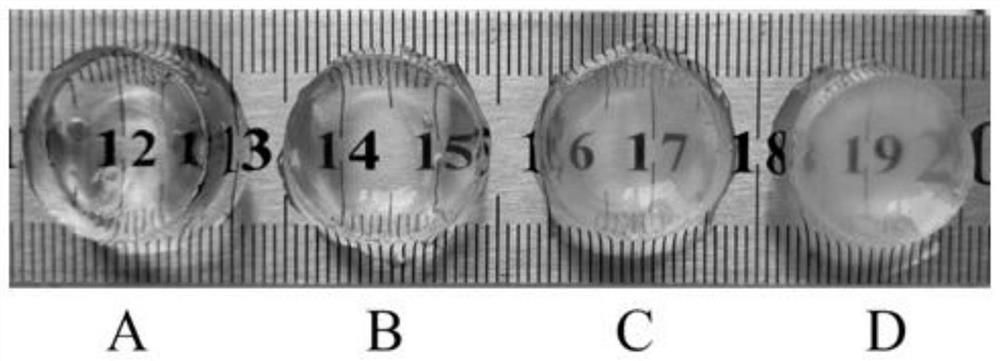

[0044]Maleimide-based cross-linked hydrolyzable POSS-PEG hybrid hydrogels were prepared by the following method: 4-arm-PEG-MAL (Mn = 20KDa, Beijing Jiankai Technology Co., Ltd.) and POSS-SH (provided by Sigma-Adrich Company) was dissolved in 3 mL of tetrahydrofuran, stirred at room temperature for 3.5 h, and then the solvent was evaporated to obtain a POSS-PEG prepolymer, which was stored at -20°C for future use. Then the POSS-PEG prepolymer and PEG-SH (Mn=4KDa) were uniformly mixed in different concentrations of triethanolamine buffer (TEA, pH=7.4) to obtain a pregel solution. Then the above pregel solution was transferred to five 600 μl molds, and reacted in a 37° C. biochemical incubator to prepare a hydrogel. The amounts of 4-arm-PEG-MAL, POSS-SH and hydrolyzable cross-linking agent, the molecular weight of 4-arm-PEG-MAL, the concentration of triethanolamine and the gelation time during the preparation process are shown in ...

Embodiment 2

[0055] Mechanical performance testing experiment

[0056] A set of hydrogels consisted of three test samples, which were swelled to equilibrium with ultrapure water, and the surface moisture was wiped dry with filter paper. The mechanical properties of the hydrogel were analyzed by rheometer, and the average value of the three test samples was taken. Figure 5 It is the oscillation stress scanning spectrum of the storage modulus (G') and the dynamic frequency scanning spectrum of the storage modulus (G') and loss modulus (G") of the hydrogel material. By Figure 5 It can be seen that when the hydrogel material prepared by the method of the present invention is subjected to an increase from 0.1Pa to 10Pa, the storage modulus (G') does not change significantly with the change of stress, and when the scanning frequency range is 0Hz to 10Hz There was also no significant change in the storage modulus (G'), indicating that the hydrogel material was well cross-linked. Compared with ...

Embodiment 3

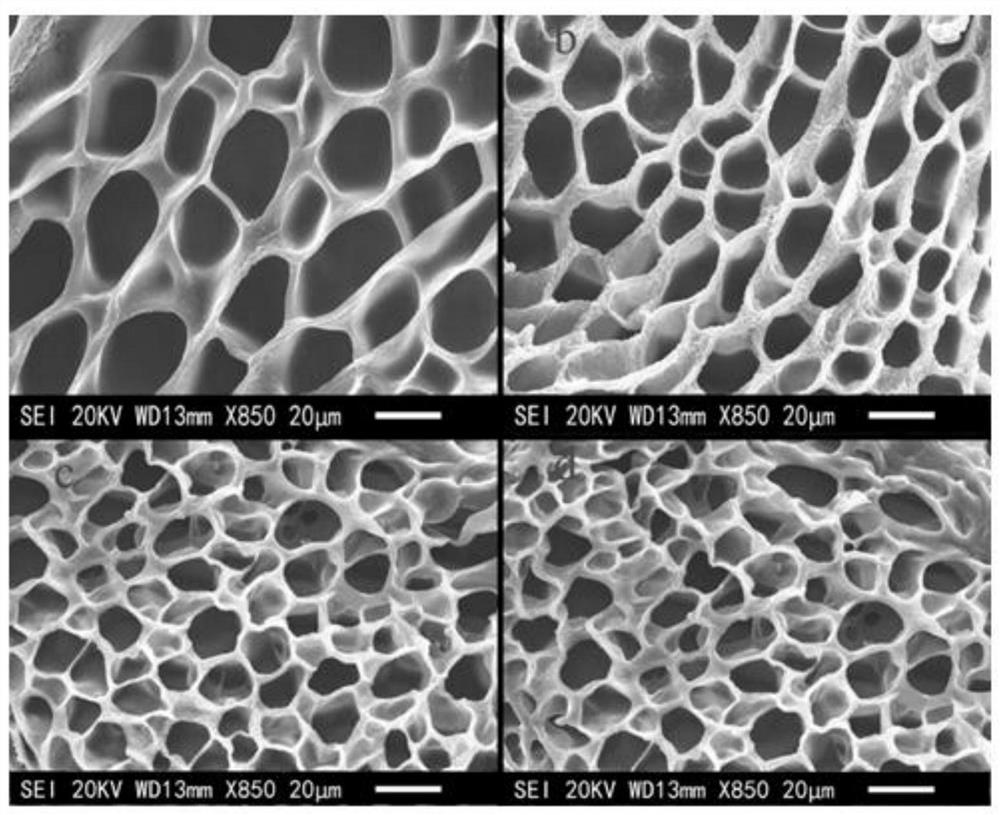

[0058] Swelling rate test experiment

[0059] A set of hydrogels consisted of 3 test samples, which were freeze-dried and weighed accurately. The dry hydrogel was immersed in 0.9% sodium chloride injection (10 mL), and placed in a constant temperature incubator at 37°C. At a predetermined time, take out the swollen hydrogel, dry the surface moisture with filter paper and weigh until the weight of the hydrogel remains constant. Swelling percentage of hydrogel (%)=(hydrogel mass after swelling−hydrogel mass before swelling) / hydrogel mass before swelling×100%, average value of 3 test samples. Image 6 is the swelling curve. Depend on Image 6 It can be seen that the hydrogel material prepared by the method of the present invention has reached a higher swelling ratio in the first 24 hours, and reached swelling equilibrium after 100 hours. Although the equilibrium swelling ratio of POSS-PEG hybrid hydrogels decreased with the increase of POSS content. However, the equilibrium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com