Sheet having air permeability, water disintegrability and water impermeability

A hydrolyzable and air-permeable technology, which is applied in transportation and packaging, medical science, clothing, etc., can solve the problems of skin touch (poor texture, low production efficiency, floating in septic tanks, etc.), and achieve excellent sedimentation and production high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

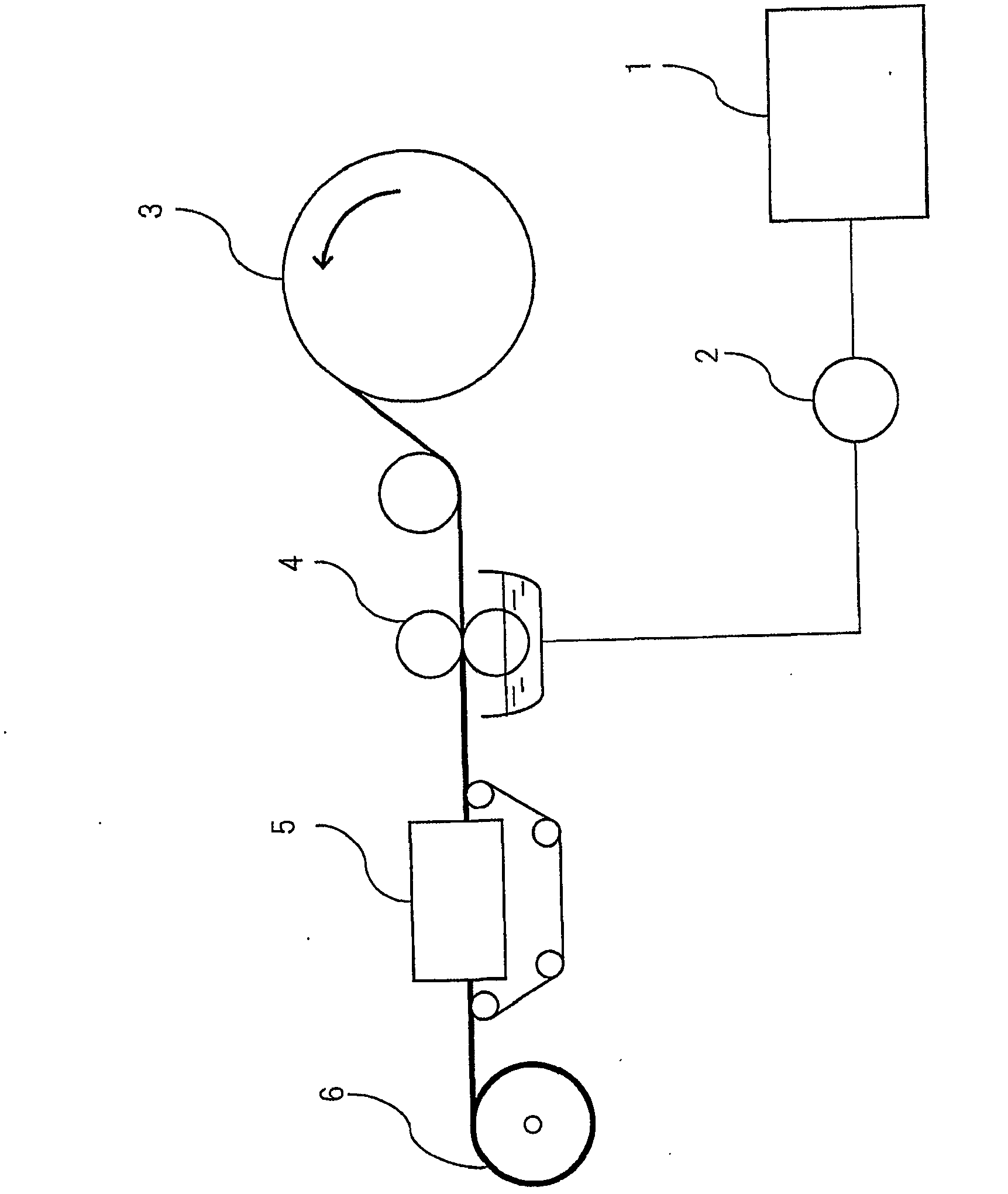

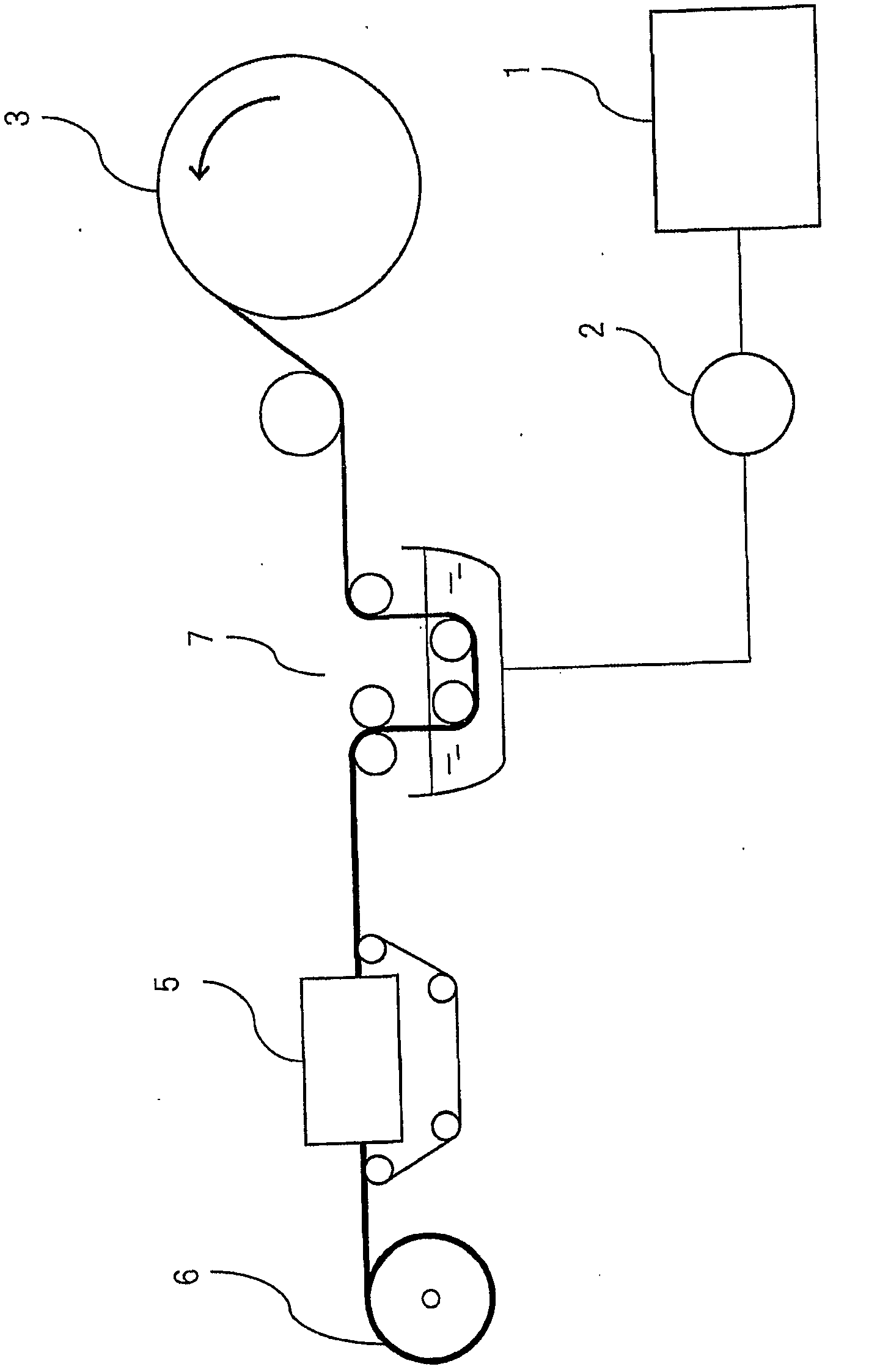

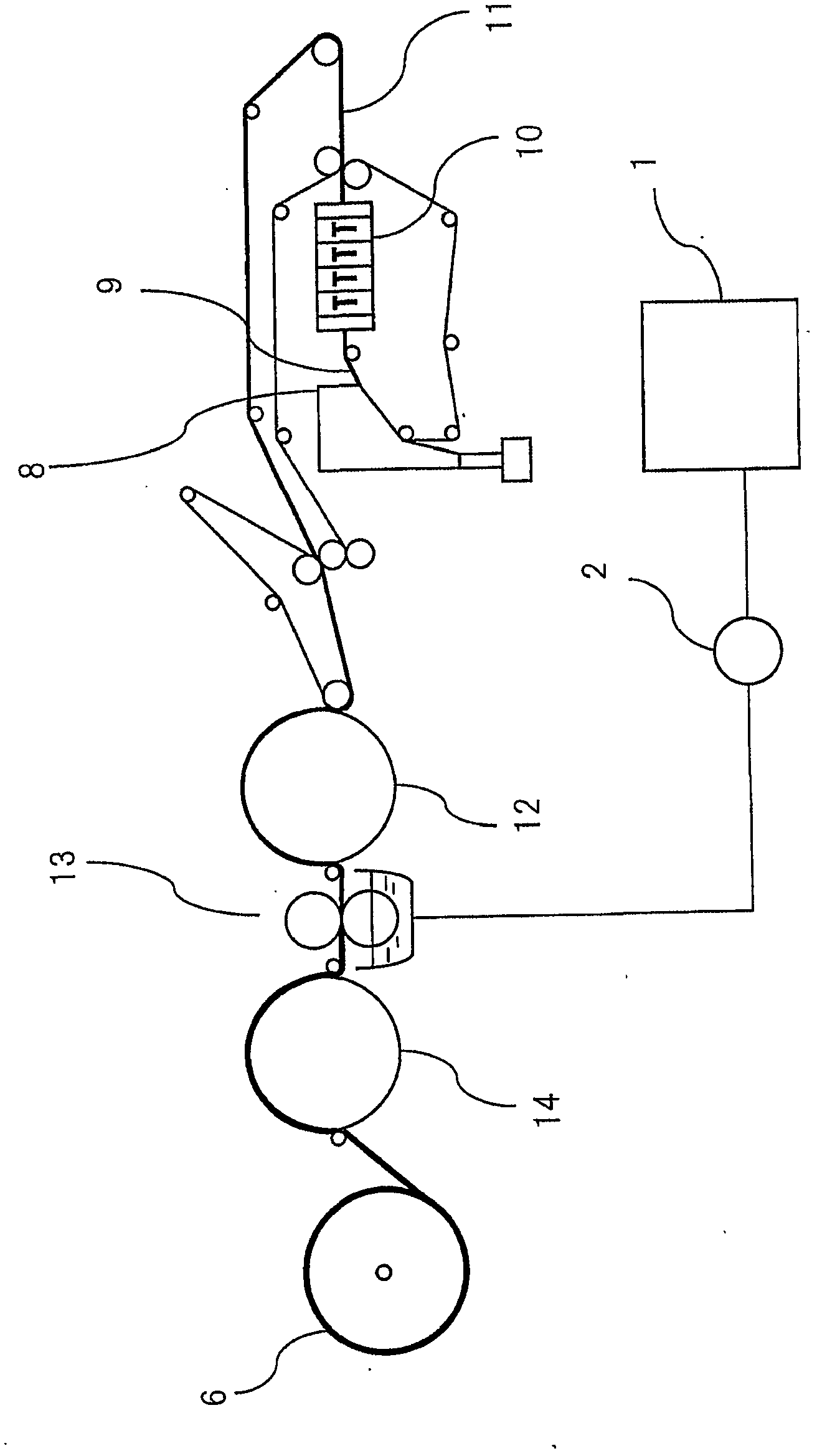

[0110] A substrate raw material slurry prepared by blending 70% by mass of NBKP and 30% by mass of rayon fibers (manufactured by Daiwabo, corona treated, 1.1dt×7mm) was introduced into image 3 In the web forming section 8 of the wet papermaking system shown, a web is formed. The formed fiber web was placed on a wire mesh for fiber web formation, and the high-pressure water treatment unit 10 applied high-pressure water treatment under the following conditions from above the fiber web while suctioning and discharging water from below the wire mesh. Squeeze, dehydrate and dry the fiber web treated with high-pressure water flow to obtain a weight per unit area of 40g / m 2 The processed fiber web 1 . A paraffin dispersion of hydrophobic nano-silica (manufactured by Nikka Chemical Co., Ltd., Adexo WR-1) was coated with a transfer gravure roll coater on the treated fiber web 1, and then dried with a hot air dryer (100° C.) to obtain The weight per unit area of hydrophobic nano ...

manufacture example 2

[0115] The paraffin dispersion liquid of hydrophobic nano-silica (manufactured by Nikka Chemical Co., Ltd., Adexo WR-1) was 1.0 g / m in weight per unit area after drying. 2 A sheet 2 was obtained in accordance with Production Example 1 except that the coating was carried out under the conditions described above.

manufacture example 3

[0117] The paraffin dispersion liquid of hydrophobic nano-silica (manufactured by Nikka Chemical Co., Ltd., Adexo WR-1) is 2.0 g / m2 after drying. 2 A sheet 3 was obtained in accordance with Production Example 1 except that the coating was carried out under the conditions described above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com