Lithium battery diaphragm material as well as preparation method and application thereof

A lithium battery separator and raw material technology, applied in the field of electrochemistry, can solve problems such as thin thickness, and achieve the effects of simple process, small discharge capacity attenuation, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

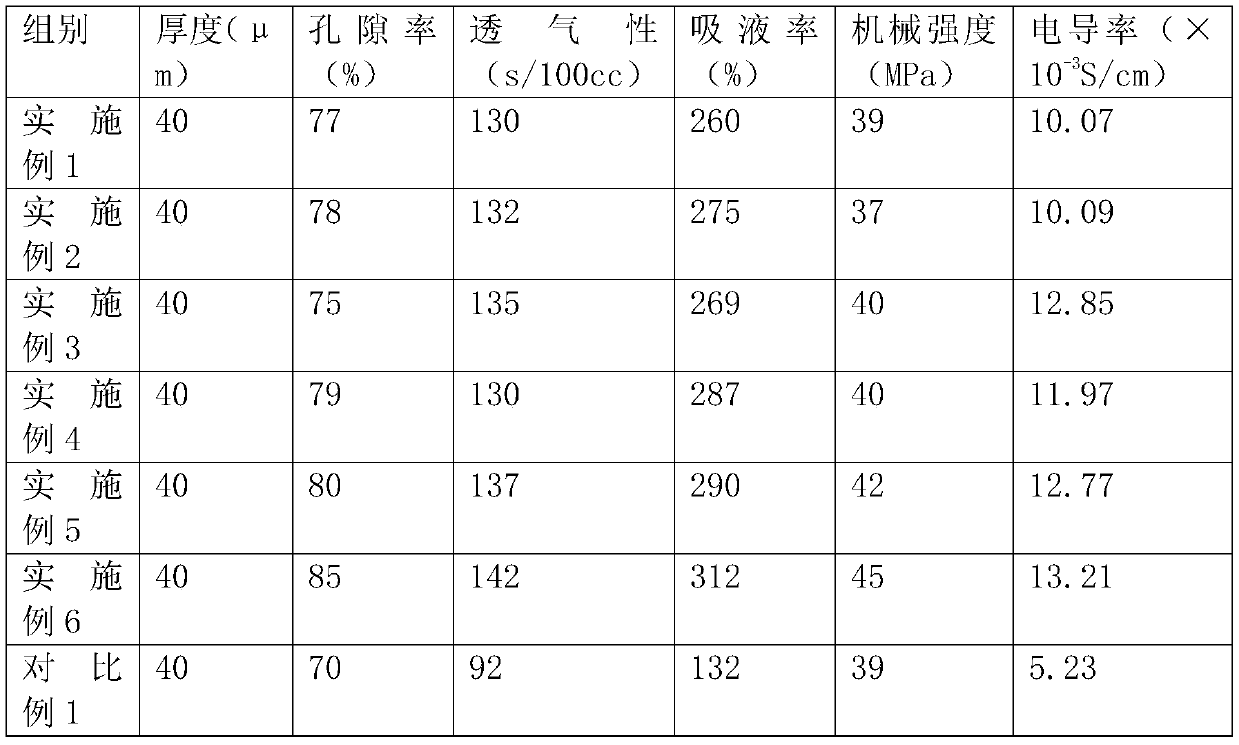

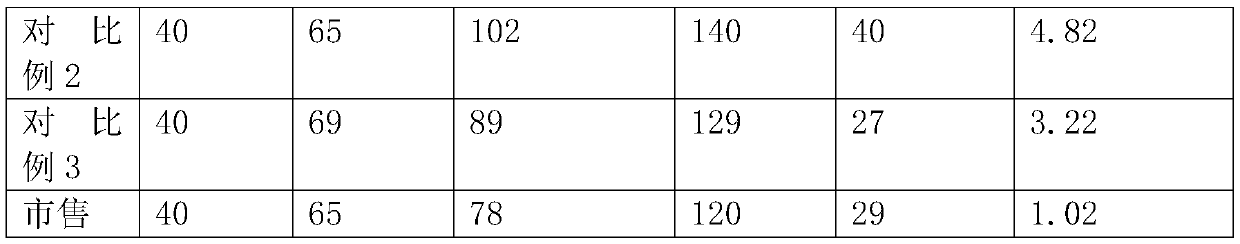

Examples

preparation example Construction

[0024] The preparation method of graphene oxide is as follows:

[0025] Step 1. Weigh 10g of natural graphite powder (G), 4g of potassium persulfate, and 10g of phosphorus pentoxide, and add them into a three-necked flask containing 24mL of sulfuric acid while stirring, and react in a constant temperature water bath at 60°C for 3h. Then move the three-neck flask to a constant temperature water bath at 25°C to react for 5 hours, filter it with suction, wash it with ionized water to neutrality, and dry it in air to obtain pre-oxidized graphite (P-G);

[0026] Step 2, take by weighing 1 g of pre-oxidized graphite, add in the there-necked flask that 25mL sulfuric acid is housed under the situation of stirring, put in the ice-water bath, after pre-oxidized graphite is all dissolved, add the potassium permanganate of 3g, react 2h, then move the three-neck flask to a constant temperature water bath at 35°C for 40min, then add deionized water, continue to react at 35°C for 1h, and fin...

Embodiment 1

[0032] Composition of raw materials (parts by weight): 5 parts of graphene oxide, 10 parts of ultra-high molecular weight polyethylene, 1 part of silver nitrate, 2 parts of tetraethyl titanate, 0.5 parts of citric acid, and 10 parts of o-dichlorobenzene.

[0033]The preparation method of lithium battery separator material, comprises the following steps:

[0034] S1. Weigh tetraethyl titanate, silver nitrate, and citric acid and dissolve them in deionized water, stir until dissolved, slowly add 15wt% ammonia water dropwise to adjust the pH value to 9, and stir the reaction at 70°C to make the solution become a hydrogel , transferred to an oven, heated and evaporated to dryness to obtain xerogel, which was transferred to a muffle furnace and heated to 450°C for roasting, and ground into a fine powder after cooling;

[0035] S2. UHMWPE is put into o-dichlorobenzene solution, heated to 120° C. in an oil bath, and after heating for 10 min, add the o-dichlorobenzene solution of grap...

Embodiment 2

[0037] Composition of raw materials (parts by weight): 10 parts of graphene oxide, 30 parts of ultra-high molecular weight polyethylene, 3 parts of silver nitrate, 5 parts of tetraethyl titanate, 3 parts of citric acid, and 20 parts of o-dichlorobenzene.

[0038] The preparation method of lithium battery separator material, comprises the following steps:

[0039] S1. Weigh tetraethyl titanate, silver nitrate, and citric acid and dissolve them in deionized water, stir until dissolved, slowly add 30wt% ammonia water dropwise to adjust the pH value to 10, and stir the reaction at 80°C to make the solution into a hydrogel , transferred to an oven, heated and evaporated to dryness to obtain xerogel, which was transferred to a muffle furnace and heated to 550°C for roasting, and ground into a fine powder after cooling;

[0040] S2. UHMWPE is put into o-dichlorobenzene solution, heated to 140° C. in an oil bath, and after heating for 30 min, add the o-dichlorobenzene solution of grap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com