Lithium-sulfur battery cathode material, preparation method thereof, electrode sheet, and lithium-sulfur battery

A technology for lithium-sulfur batteries and positive electrode materials, applied in battery electrodes, non-aqueous electrolyte battery electrodes, lithium batteries, etc., can solve the problems of reducing the utilization rate of active material sulfur, low energy density of batteries, and increasing production costs, so as to improve cycle life. Stability, facilitate wetting, and improve utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a preparation method of the cathode material of lithium-sulfur battery, the preparation method mainly includes the following steps:

[0029] Step 1: heat-treat sulfur powder to obtain liquid sulfur, and then add organic matter into the liquid sulfur for high-temperature solidification. Specifically, the heat treatment is carried out in the air, accompanied by a stirring process, and the specific heat treatment method is to heat up to 175° C. to 185° C. and then keep the temperature at this temperature for 3 hours to 6 hours.

[0030] Step 2: After grinding the mixture obtained in Step 1, heat treatment is carried out under the condition of flowing inert gas, so as to make further copolymerization reaction of sulfur and organic matter, thereby obtaining the positive electrode material of the lithium-sulfur battery. Specifically, the inert gas is nitrogen or argon, the heat treatment temperature is 250°C-350°C, the heating rate is 2-5°C...

Embodiment 1

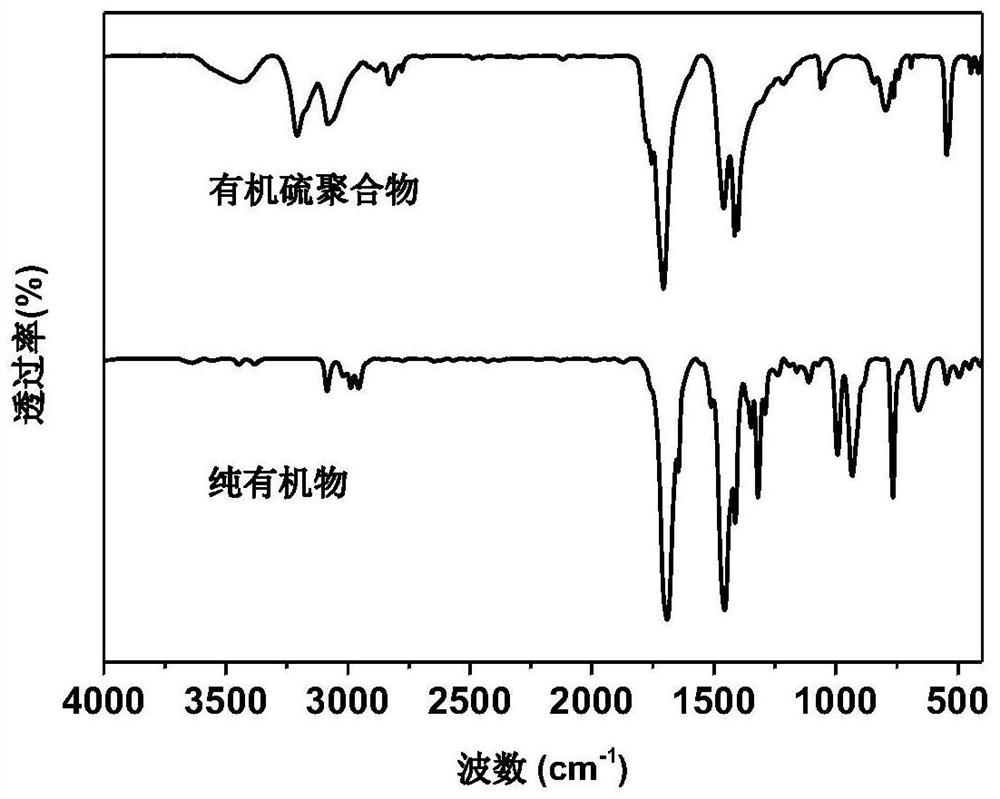

[0041] A positive electrode material for a lithium-sulfur battery is an organic sulfur polymer material with a relatively high sulfur content, and the organic sulfur polymer material is formed through a copolymerization reaction of liquid sulfur formed after melting organic matter and sulfur powder.

[0042]The preparation method of the above-mentioned lithium-sulfur battery cathode material is:

[0043] a) Heating 0.3g of sulfur powder to 175°C to 185°C to obtain liquid sulfur, adding 2.7g of organic matter to the liquid sulfur and keeping it at this temperature for 3h to 6h for high temperature curing; b) Grinding the material obtained in step a) Afterwards, pass in an inert gas and conduct heat treatment at 250°C. The heating rate during heat treatment is 2-5°C / min, and then keep it at 250°C for 4 hours to further copolymerize sulfur and organic matter to obtain the lithium-sulfur battery cathode material.

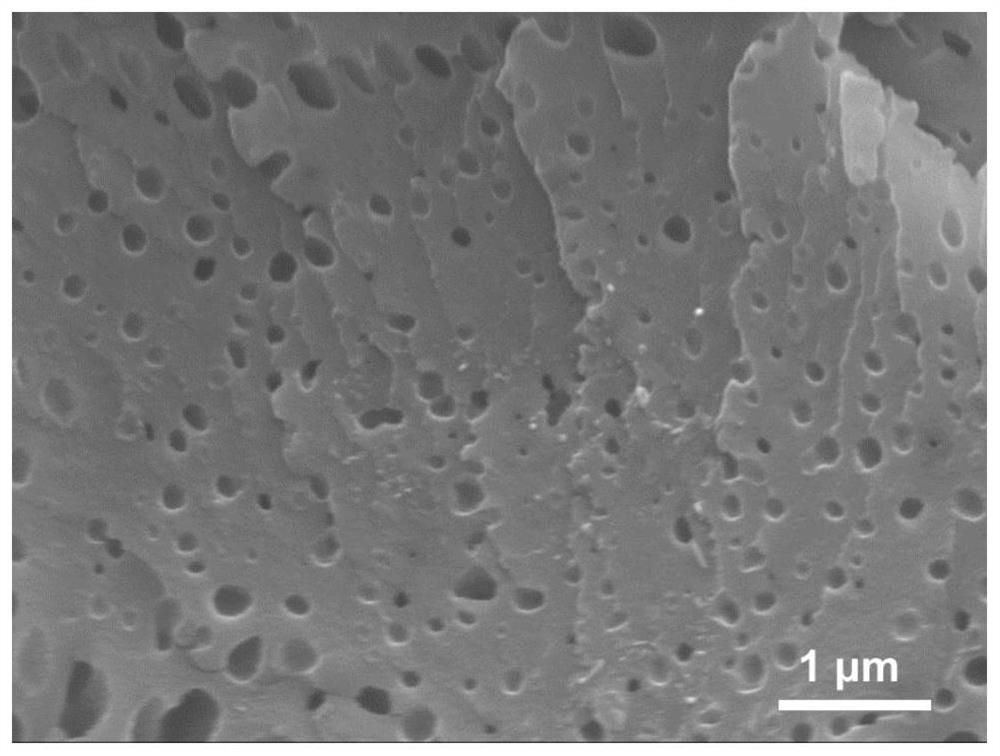

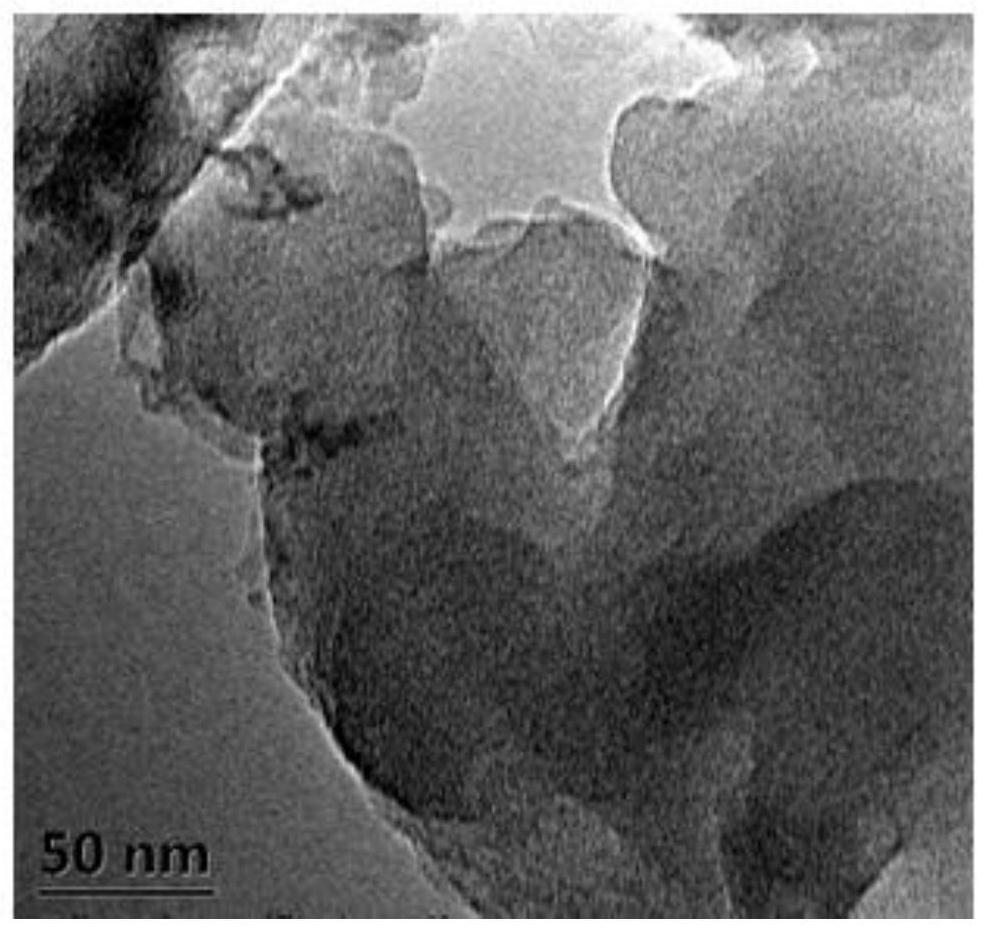

[0044] see figure 1 and figure 2 , it can be seen that the sur...

Embodiment 2

[0048] A positive electrode material for a lithium-sulfur battery is an organic sulfur polymer material with a relatively high sulfur content, and the organic sulfur polymer material is formed through a copolymerization reaction of liquid sulfur formed after melting organic matter and sulfur powder.

[0049] The preparation method of the above-mentioned organosulfur polymer material comprises the following steps:

[0050] a) heating 1g of sulfur powder to 175°C to 185°C to obtain liquid sulfur, then adding 3g of organic matter into the liquid sulfur and then keeping it at this temperature for 3 to 6 hours to perform high temperature curing; b) making the material obtained in step a) After grinding, pass in an inert gas and conduct heat treatment at 250°C with a heating rate of 2-5°C / min, and then keep it at 250°C for 4 hours to further copolymerize sulfur and organic matter to obtain the organic sulfur polymerization anode material. The cathode material of the lithium-sulfur ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com