New lithium sulfur battery positive electrode and lithium sulfur battery comprising new lithium sulfur battery positive electrode

A lithium-sulfur battery and positive electrode technology, applied in the field of chemical power sources, can solve the problems that limit the large-scale application of lithium-sulfur batteries, the utilization rate of active materials and the battery cycle characteristics cannot meet commercial applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

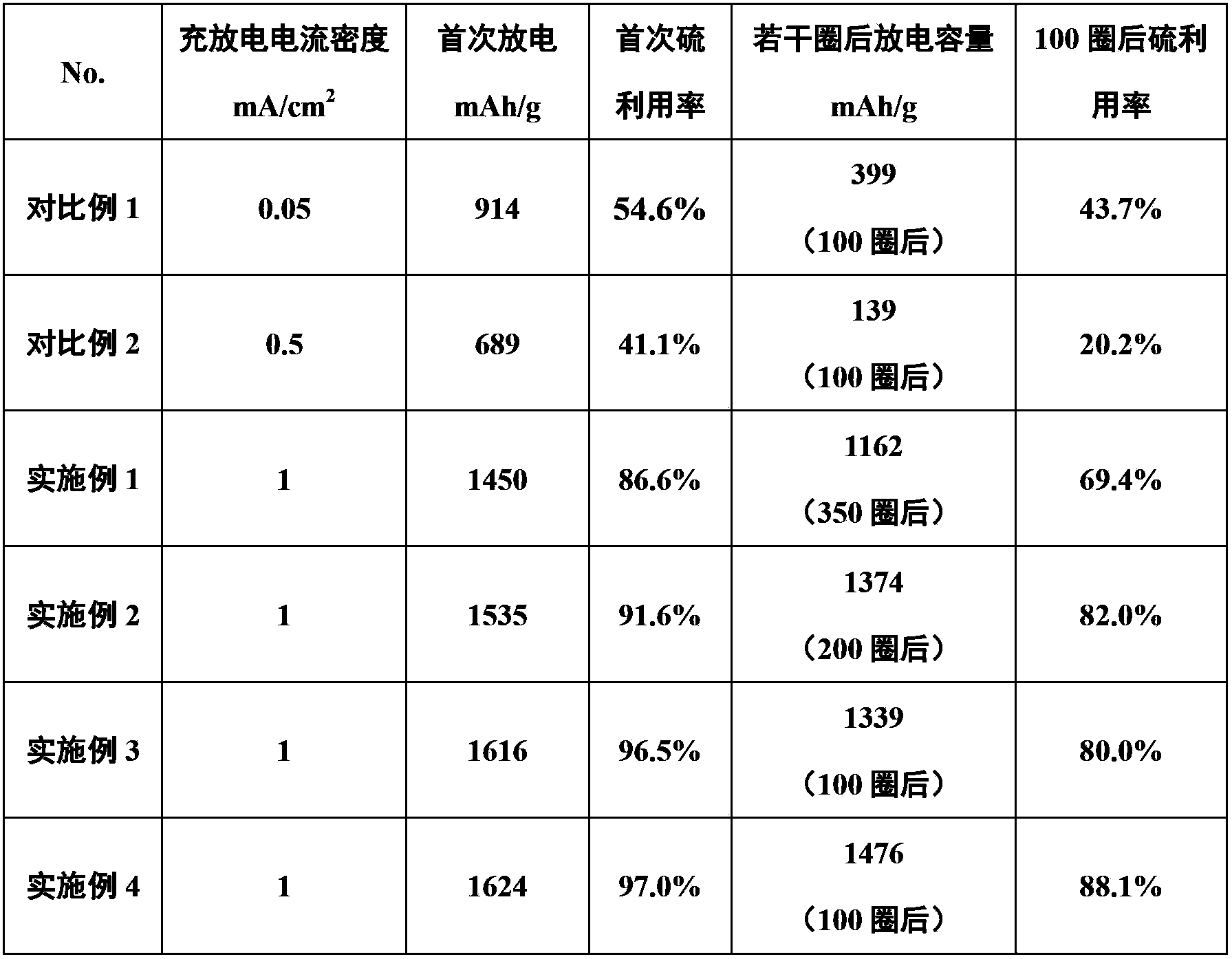

Embodiment 1

[0041] Mix the active sulfur powder of 60 parts by weight and the conductive agent acetylene black of 30 parts by weight, and grind and mix homogeneously with a mortar to obtain positive active material powder; 10 parts by weight of binder PVDF are dissolved in 90 parts by weight of solvent N- A binder solution prepared in methyl-2-pyrrolidone; with solvent N-methyl-2-pyrrolidone, 90 parts by weight of the positive electrode active material powder and 100 parts by weight of the binder solution are mixed and stirred for 1 hour or longer Time, prepare the powder slurry of the positive electrode active material including the binder coating; apply the powder slurry on the copper foil current collector with an automatic coating machine, and vacuum dry it in an oven at 60°C for 10~24h The solvent was removed to prepare a positive electrode sheet for the lithium-sulfur battery of Example 1 in the embodiment of the present invention, wherein the weight ratio of sulfur-containing elemen...

Embodiment 2

[0044] Mix 65 parts by weight of active sulfur powder and 30 parts by weight of conductive agent acetylene black, and grind and mix uniformly with a mortar to obtain positive active material powder; use solvent N-methyl-2-pyrrolidone to prepare and mix the above positive active material powder, An aqueous solution containing 2 parts by weight of the CMC adhesive, an emulsion containing 3 parts by weight of the SBR adhesive, stirred for 1 hour or longer, and prepared into a powder slurry comprising a positive electrode active material of the binder coating; The powder slurry is coated on the copper foil current collector with an automatic coating machine, and vacuum-dried in an oven at 60°C for 10-24 hours to remove the solvent, and the positive electrode sheet for the lithium-sulfur battery of Example 2 in the embodiment of the present invention is obtained , wherein the weight ratio of sulfur-containing elements is 65%.

[0045] Using the positive electrode material and metal...

Embodiment 3

[0047] Mix 75 parts by weight of active sulfur powder, 75 parts by weight of electrolytic copper powder, 20 parts by weight of conductive agent acetylene black, and grind and mix uniformly with a mortar to obtain positive active material powder; use solvent N-methyl-2-pyrrolidone to prepare Mix the above-mentioned positive electrode active material powder, an aqueous solution containing 2 parts by weight of the CMC adhesive, and an emulsion containing 3 parts by weight of the SBR adhesive, and stir for 1 hour or longer to prepare a positive electrode active material including a binder coating. Powder slurry; the powder slurry is coated on the copper foil current collector with an automatic coating machine, and vacuum-dried in an oven at 60°C for 10 to 24 hours to remove the solvent, and the powder used in Example 3 in the embodiment of the present invention is obtained. Positive pole piece of lithium-sulfur battery.

[0048] Using the positive electrode material and metal lith...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com