Preparation method of carbon nanotube-lithium sulfide-carbon composite material

A carbon composite material, carbon nanotube technology, applied in lithium batteries, electrochemical generators, electrical components, etc., can solve the problems of low electron/ion conductivity, easy to cause shuttle effect, limit practical application, etc., to achieve electrical conductivity Good, inhibiting dissolution and diffusion, and the effect of tight coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment includes the following steps:

[0024] (1) Dissolve 0.002mol of sublimated sulfur powder in 200ml of toluene at a temperature of 60°C to form a uniform and transparent solution A;

[0025] (2) Disperse 3 mg of carbon nanotubes in 4 ml of tetrahydrofuran solution of lithium triethylborohydride with a concentration of 1 mol / L, and ultrasonically disperse for 10 min to make them uniformly dispersed in the solution to form suspension B;

[0026] (3) Add solution A to suspension B, stir for 1 min, stir, heat and evaporate to dryness to form carbon nanotube-Li 2 S powder; heating temperature is 100°C;

[0027] (4) The carbon nanotube-Li obtained in step (3) 2 Under the protection of argon, the temperature of S powder was raised to 450°C for 0.5h, and then acetylene gas was introduced to conduct vapor phase deposition of carbon. The deposition time was 0.5h, and then cooled to room temperature to obtain carbon nanotube-Li 2 S-C composites; controlling the qu...

Embodiment 2

[0034] This embodiment includes the following steps:

[0035] (1) Dissolve 0.002mol of sublimated sulfur in 2ml of toluene at a temperature of 110°C to form a uniform and transparent solution A;

[0036] (2) Disperse 4.6 mg of carbon nanotubes in 200 ml of tetrahydrofuran solution of lithium triethylborohydride with a concentration of 0.1 mol / L, ultrasonically disperse for 4 hours to form suspension B;

[0037] (3) Add solution A to suspension B, stir for 2 hours, stir, heat and evaporate to dryness to form carbon nanotube-Li 2 S powder; heating temperature is 150°C;

[0038] (4) Heat the product obtained in step (3) under the protection of argon to 600°C for 10 hours, then pass in acetylene gas for vapor deposition of carbon, the deposition time is 24 hours, and the quality of vapor deposition carbon is controlled to be carbon nanotube- Li 2 20wt% of the total mass of S-C, and then cooled to room temperature to obtain carbon nanotube-Li 2 S-C composites.

[0039] Embodimen...

Embodiment 3

[0041] This embodiment includes the following steps:

[0042] (1) Dissolve 0.002mol of sublimated sulfur in 15ml of toluene at a temperature of 90°C to form a uniform and transparent solution A;

[0043] (2) Disperse 9.2 mg of carbon nanotubes in 10 ml of a tetrahydrofuran solution of lithium triethylborohydride at a concentration of 1 mol / L, and disperse it ultrasonically for 4 hours to form a suspension B;

[0044] (3) Add solution A to suspension B, stir for 1 hour, stir, heat and evaporate to dryness to form carbon nanotube-Li 2 S powder; heating temperature is 120°C;

[0045] (4) Heat the product obtained in step (3) under the protection of argon to 550°C for 1 hour, then pass in acetylene gas for vapor deposition of carbon, the deposition time is 3 hours, and the content of vapor deposition carbon is controlled to be carbon nanotube- Li 2 2wt% of the total S-C content, then cooled to room temperature, CNT-Li 2 S-C composites.

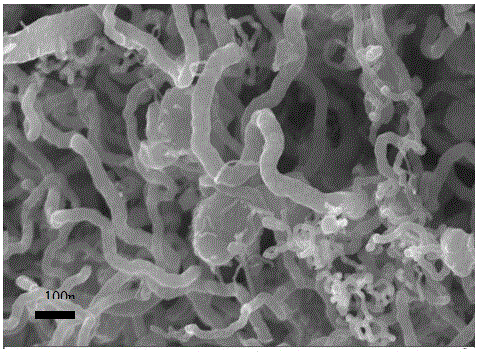

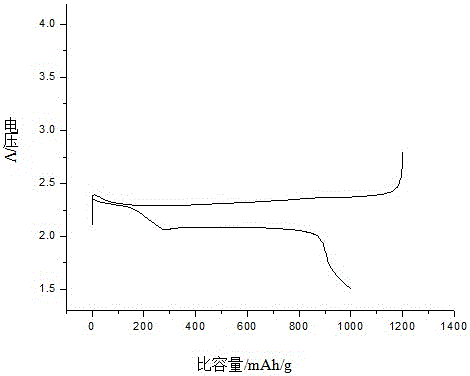

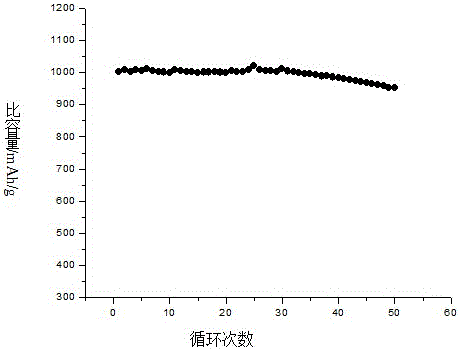

[0046] Embodiment 3 gained carbon nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com