Molybdenum carbide sulfur composite material and preparation method and application thereof

A composite material, molybdenum carbide technology, used in electrical components, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of unsatisfactory cycle performance and service life of carbon-sulfur composites, weak interaction, etc., and achieve good cycle stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a preparation method for the above-mentioned molybdenum carbide-sulfur composite material, comprising the following steps:

[0033] 1) after molybdenum trioxide raw material, hydrogen peroxide and nitric acid solution are mixed, obtain rod-shaped molybdenum trioxide through hydrothermal treatment;

[0034] 2) mixing the rod-shaped molybdenum trioxide, carbon precursor material and solvent, and performing a reduction reaction under a protective atmosphere to obtain molybdenum carbide;

[0035] 3) mixing the molybdenum carbide and sulfur element, and performing heat treatment under a protective atmosphere to obtain a molybdenum carbide-sulfur composite material.

[0036] The invention mixes molybdenum trioxide raw material, hydrogen peroxide and nitric acid solution to obtain a mixed solution. The present invention does not have special requirements for the source of molybdenum trioxide raw material, hydrogen peroxide and nitric acid s...

Embodiment 1

[0060] Prepare a mixed solution (0.3g / ml hydrogen peroxide 20ml, 0.65g / ml nitric acid solution 10ml), add 0.4g molybdenum trioxide to the mixed solution and stir for 72 hours at a stirring rate of 500r / min; then hydrothermally treat at 190°C for 36 hours, cooled to room temperature, centrifuged, filtered, and dried at 70°C to obtain rod-shaped molybdenum trioxide;

[0061] Disperse the above-prepared rod-shaped molybdenum trioxide and phenolic resin in 40ml of ethanol solvent at a mass ratio of 2:1, stir at 40°C for 28 hours, and dry at 80°C to obtain a solid mixed powder. Mix the solid powder in N 2 Sintering in a protected high-temperature furnace, at a heating rate of 5°C / min, raised to 900°C for sintering reaction for 18 hours, and naturally cooled to room temperature to obtain molybdenum carbide;

[0062] The prepared molybdenum carbide and sulfur element were ball milled in a ball mill for 4 hours according to the mass ratio of 2:3, and the product was 2 In a protected...

Embodiment 2

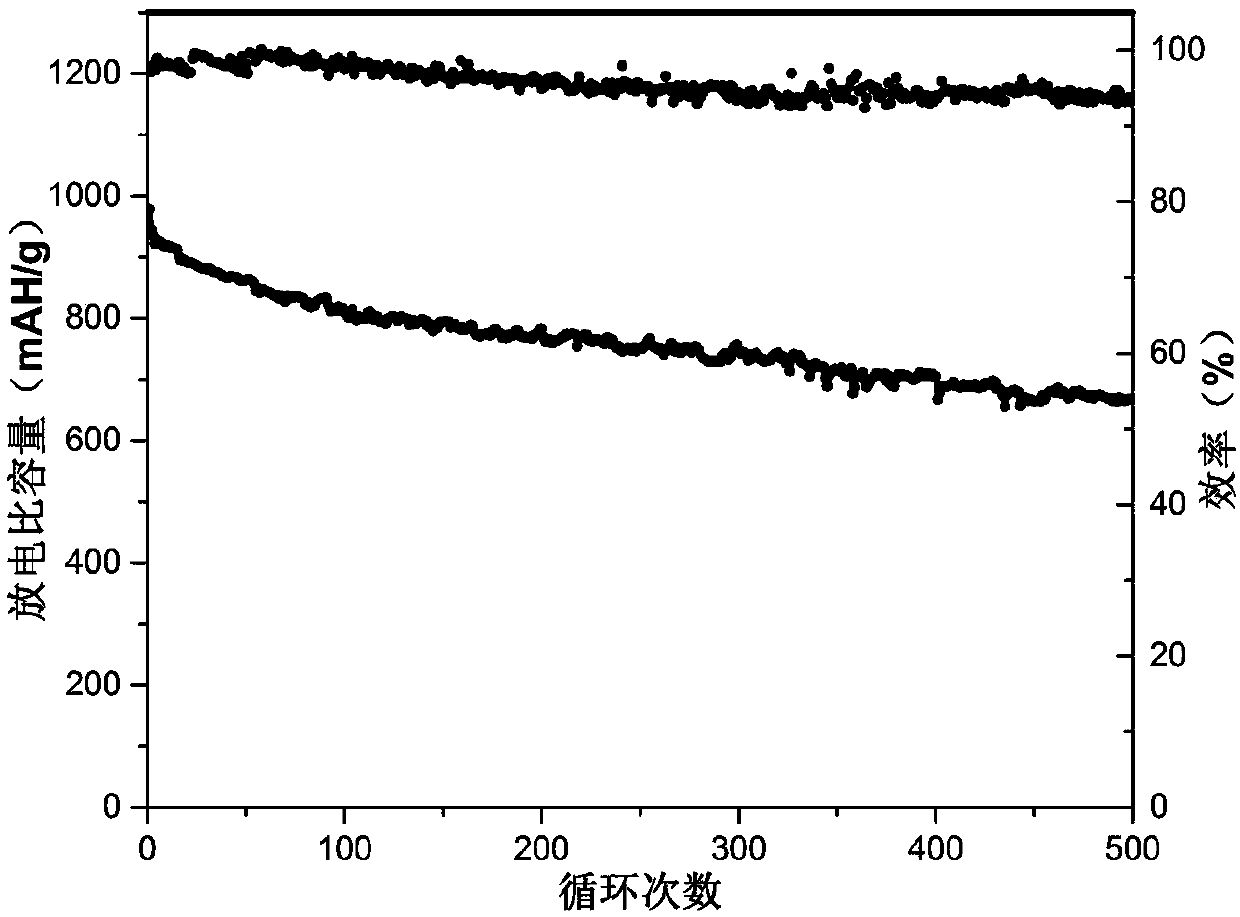

[0065] Preparation of lithium-sulfur battery: mix the molybdenum carbide-sulfur composite material prepared in Example 1 with acetylene black and PVDF at a mass ratio of 8:1:1, and use N-methylpyrrolidone as a solvent to make a uniform slurry (solid content 50%), and coated on the aluminum foil, dried to obtain the positive sheet, in the argon-protected glove box, with metal lithium as the negative electrode, 1M LiTFSI, 0.1M LiNO 3 (DOL and DME are solvents with a volume ratio of 1:1) as the electrolyte and assembled into a button lithium-sulfur battery.

[0066] Cycle performance test: at a constant temperature of 30°C, within a voltage range of 1.5-3.0V, a charge-discharge test is performed at a current density of 1C, and the cycle is 500 times.

[0067] Depend on figure 2 The cycle performance curve of the positive electrode material shown shows that after 500 cycles, it still maintains a reversible capacity of 653mAh / g, and after 500 cycles at a 1C rate, the retention ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com