Method for efficiently removing copper through crude bismuth pot refining

A technology of coarse bismuth and bismuth pot, which is applied in the field of metallurgical technology, can solve the problems of increasing bismuth production cost, prolonging the copper removal cycle, and low sulfur utilization rate, so as to improve the sulfur utilization rate, reduce the amount of fish out, and shorten the copper removal cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

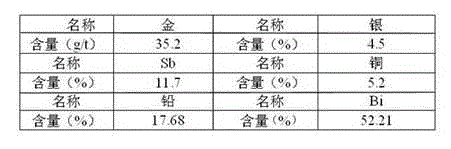

[0015] Implementation Case 1: Thick bismuth is taken as an example containing the following elements, and its element content is shown in Table 1:

[0016] Table 1

[0017]

[0018] Take the following process steps:

[0019] 1. Add 3.5t of crude bismuth into the bismuth pot by driving, ventilate and pass oil, and control the air-oil ratio of 1:0.02 (volume ratio). After the bismuth is completely melted at 530°C, remove the scum;

[0020] 2. Mix 50kg of sulfur and 20kg of sawdust, and add 15L of clear water until the mixture is evenly mixed, and no water will come out of your hands. Control the temperature at 540°C. The amount is about 12kg) into the bismuth pot, stop adding sulfur when the copper drops to less than 0.005%;

[0021] 3. Raise the temperature to 650°C, insert the iron pipe into the melt, and pass in the compressed air to oxidize and remove antimony, arsenic, and tellurium (control the compressed air pressure at 0.2mpa, and the air volume at 1.5m 3 / min), w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com