110KV low-power-consumption environmentally-friendly power transformer

A technology for power transformers and transformers, applied in the field of transformers, can solve the problems of insulating oil or SF6 gas leakage, installation, use, maintenance, high price, etc., to eliminate environmental hazards, high safety and reliability, and save insulation devices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

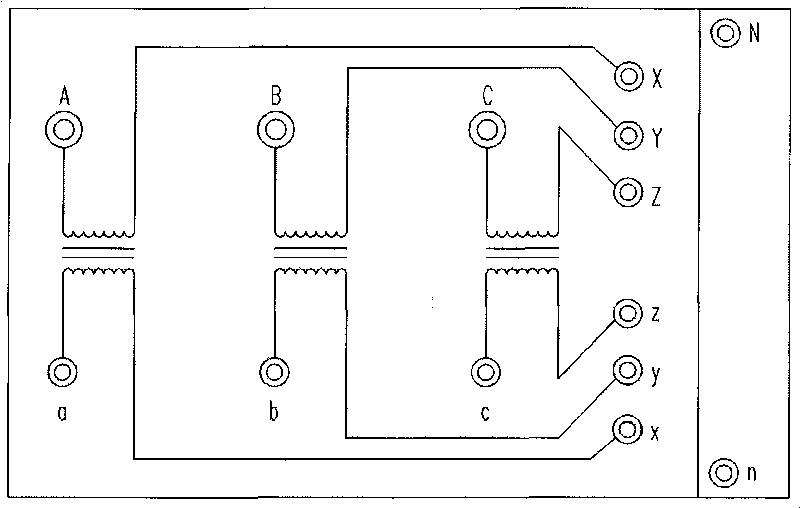

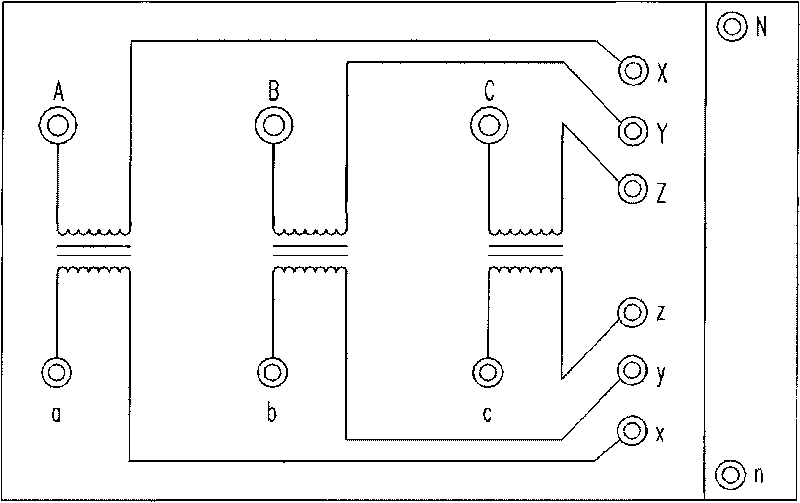

[0015] Embodiment 1, the 110KV series low energy consumption and environment-friendly power transformer of the present invention is that the ends of the three-phase windings on the Y-connected side of the transformer are connected separately, and the ends of the three-phase windings of the oil-immersed transformer are respectively connected outside the outlet body, and the ends of the dry-type transformer are connected separately. The ends of the three-phase windings are respectively connected inside the transformer body or connected outside the transformer body.

Embodiment 2

[0016] Embodiment 2, the 110KV series low energy consumption and environment-friendly power transformer of the present invention is that the ends of the three-phase windings on the Y-connected side of the transformer are connected separately, and the terminals are respectively arranged after connecting; the three-phase winding ends of the oil-immersed transformer are respectively connected and led out Outside the body of the transformer, the ends of the three-phase windings of the dry-type transformer are respectively connected inside the body of the transformer or connected outside the body of the transformer.

Embodiment 3

[0017] Embodiment 3, the 110KV series low energy consumption and environment-friendly power transformer of the present invention is that the ends of the three-phase windings on the Y-connected side of the transformer are connected separately, and the terminals are respectively arranged after connecting; the three-phase winding ends of the oil-immersed transformer are respectively connected and led out Outside the body of the transformer, the ends of the three-phase windings of the dry-type transformer are respectively connected inside the body of the transformer or connected outside the body of the transformer. The ends of the three-phase windings on the Y-connected side of the oil-immersed transformer are respectively provided with fixed terminals outside the transformer body, and the dry-type transformer is provided with fixed terminals outside the body or inside the body or on the side of the winding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com