Downhole oil-submerged diaphragm pump

A technology of diaphragm pumps and diaphragms, which is applied in the direction of pumps, wellbore/well parts, pumps with flexible working elements, etc., can solve the problems of high maintenance operation costs, breakage, high manufacturing costs, etc., and achieve high maintenance operation costs, Effect of prolonging service life and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

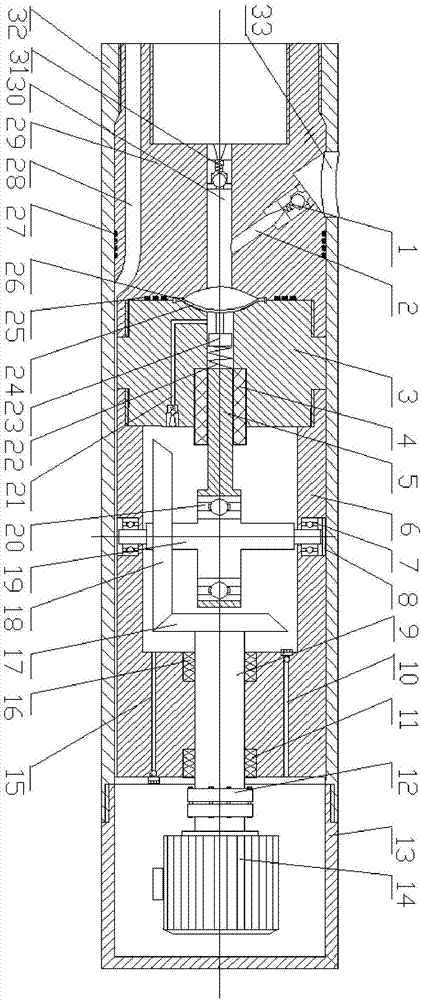

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0030] See attached figure 1 , the downhole submersible diaphragm pump of the present invention includes a liquid inlet valve assembly 1, a cylinder body 3, a connecting rod plunger 5, a transmission box body 6, a transmission shaft 9, a coupling 12, a motor 14, and a conical pinion 17 , Conical bull gear 18, eccentric shaft 19, spring 22, righting block 23, diaphragm 24, valve box 29, drain valve assembly 31, sheath 32.

[0031] Among them, the motor 14 and the transmission shaft 9 are connected through a coupling 12, the second seal 11 and the third seal 16 are respectively installed between the transmission shaft 9 and the transmission box 6, and the shaft end of the transmission shaft 9 is equipped with a bevel pinion 17. The conical pinion 17 meshes with the conical large gear 18. The conical large gear 18 is mounted on the eccentric shaft 19. The eccen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com