Drying system

A drying system and drying chamber technology, which can be used in drying gas arrangement, local stirring dryer, static material dryer, etc., can solve problems such as increasing system operation energy consumption and time, inconsistent material drying progress, and large drying chamber resistance. , to achieve the effect of maximizing heat utilization, synchronizing effective drying, and maximizing dehumidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

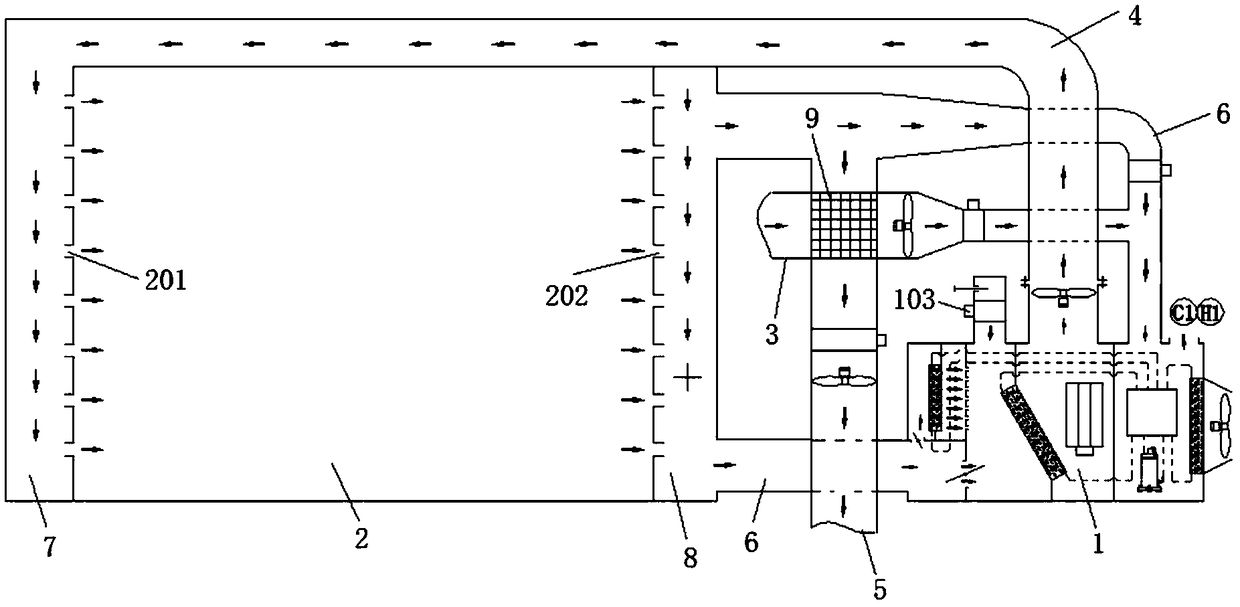

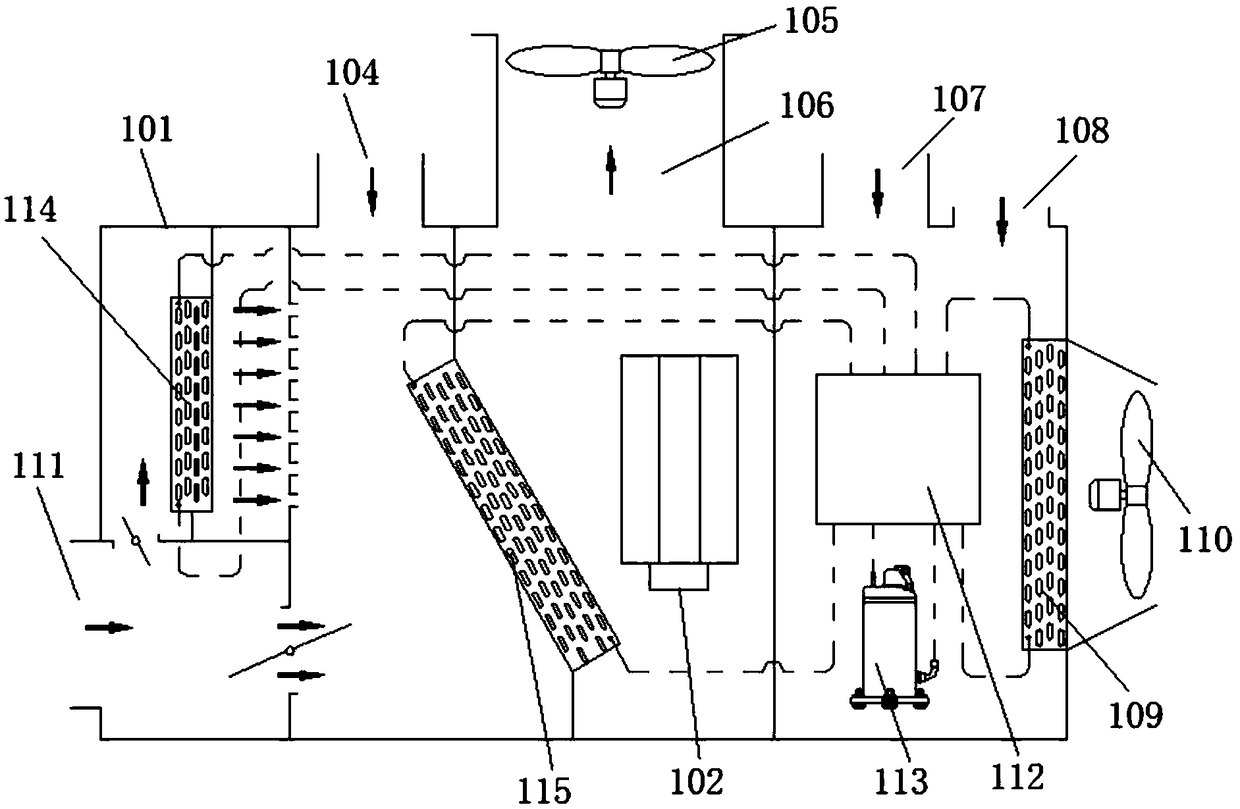

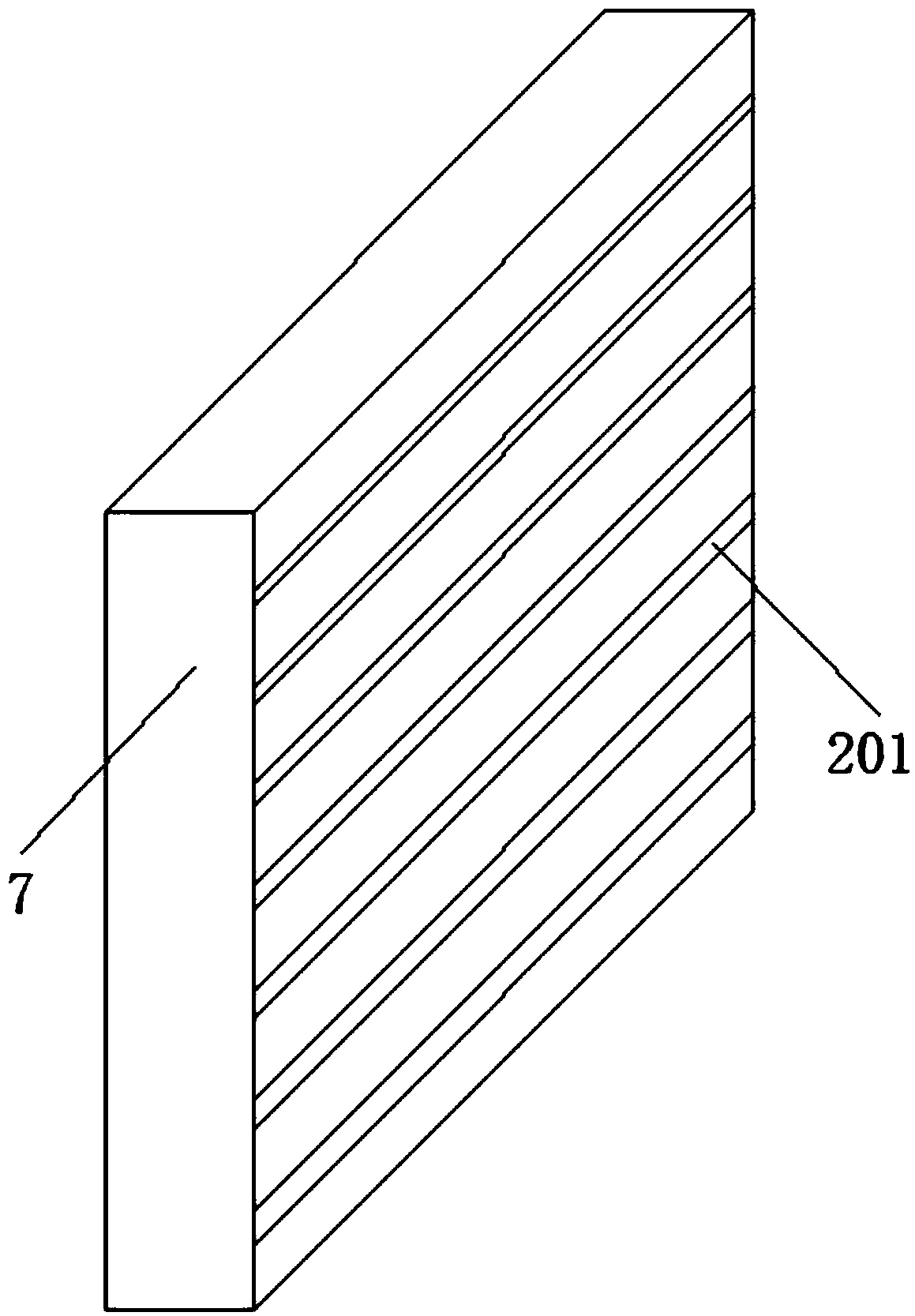

[0032] see Figure 1 to Figure 4 , Figure 1 to Figure 4 A specific embodiment of a drying system of the present invention is provided, wherein, figure 1 It is a schematic diagram of the overall structure of the drying system disclosed in Embodiment 1 of the present invention; figure 2 It is a structural schematic diagram of the heat pump unit disclosed in Embodiment 1 of the present invention; image 3 It is a schematic structural diagram of the air supply chamber disclosed in Embodiment 1 of the present invention; Figure 4 It is a schematic structural diagram of the return air chamber disclosed in Embodiment 1 of the present invention.

[0033] Such as Figure 1 to Figure 4 As shown, the drying system provided by the present invention can realize the simultaneous drying of materials in different areas of the drying chamber, greatly optimize the drying quality of materials, and reduce the energy consumption and time of system operation. The drying system includes a hea...

Embodiment 2

[0060] see Figure 5 to Figure 8 , Figure 5 to Figure 8 Another specific embodiment of a drying system of the present invention is provided, wherein, Figure 5 It is a schematic diagram of the connection of the pipe valve assembly in the return air heating state disclosed in Embodiment 2 of the present invention; Figure 6 It is a schematic diagram of the connection of the pipe valve assembly in the return air heating and dehumidification state disclosed in Embodiment 2 of the present invention; Figure 7 It is a schematic diagram of the connection of the pipe valve assembly under the high-temperature return air refrigeration state disclosed in Embodiment 2 of the present invention; Figure 8 It is a schematic diagram of the connection of the pipe valve assembly in the return air low-temperature refrigeration state disclosed in Embodiment 2 of the present invention;

[0061] Such as Figure 5 to Figure 8As shown, the pipe valve assembly provided in this embodiment include...

Embodiment 3

[0117] see Figure 9 , Figure 9 Another specific embodiment of the present invention is provided, wherein, Figure 9 It is a schematic diagram of the overall structure of the drying system disclosed in Example 3 of the present invention.

[0118] In this embodiment, the air outlets 201 are evenly distributed on the upper side wall of the drying chamber 2 from left to right, and the air outlets 202 are evenly distributed on the lower side wall of the drying chamber 2 from left to right.

[0119] In this embodiment, the air blower 105 is connected to the vertically arranged air supply chamber (adjusted from the horizontally arranged air supply chamber in Embodiment 1 to a vertical air supply chamber) through the air supply pipe 4, and the vertical air supply port of the air supply chamber is arranged vertically 201 communicates with the drying chamber 2, the air outlet 202 communicates with the drying chamber 2, and finally can be connected with the main return air outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com