Treatment method and device for flue gas of rare earth electrolytic cell

A flue gas treatment, electrolyzer technology, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problem of high energy consumption in flue gas treatment, achieve the effect of increasing operating energy consumption, improving energy consumption, and maintaining heat balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

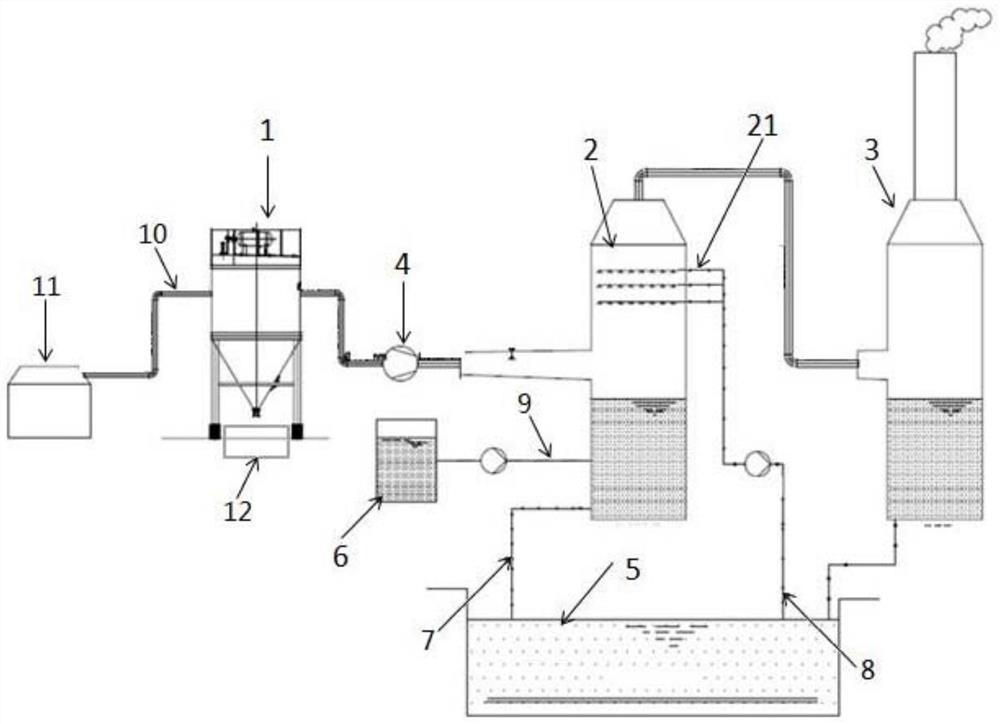

[0023] The embodiment of the present invention provides a rare earth electrolyzer flue gas treatment device, its structure is as follows figure 1 As shown, it includes a bag filter 1, an induced draft fan 4, a desulfurization and defluorination tower 2, and a demisting tower 3 connected in sequence through pipelines. The desulfurization and defluorination tower 2 is provided with a spray layer 21 for spraying lye. The bag dust collector 1, the induced draft fan 4, the desulfurization and defluorination tower 2 and the demisting tower 3 can all use existing equipment, and the specific selection of the present invention is not limited.

[0024] The bag filter 1 is used for dust removal. In this embodiment, the material of the filter bag of the bag filter 1 is one of Flumes, basalt, pre-oxidized silk composite carbon fiber, P84, and PTFE coating, and the temperature resistance is guaranteed to reach 200 Above ℃, avoid burning bag caused by high temperature gas. see figure 1 , t...

Embodiment 2

[0029] This embodiment provides a method for treating flue gas from a rare earth electrolytic cell. This method is implemented in the flue gas treatment device of a rare earth electrolytic cell in the above-mentioned embodiment 1, which can recover the valuable rare earth raw materials in the flue gas to the greatest extent, and make the Emissions meet environmental protection requirements.

[0030] see figure 1 , the method specifically includes the following steps:

[0031] (1) Use the bag filter 1 to cooperate with the induced draft fan 4 for dust removal, and the processing air volume of the bag filter 1 is 850-4600m 3 / h, for example 900m 3 / h, 1150m 3 / h, 1500m3 / h, 1800m 3 / h, 2050m 3 / h, 2100m 3 / h, 2220m 3 / h, 2350m 3 / h, 2450m 3 / h, 2750m 3 / h, 3150m 3 / h, 3600m 3 / h, 4000m 3 / h, 4350m 3 / h etc. The filtering wind speed of the bag filter 1 is 0.3-2.5m / min, such as 0.33m / min, 0.42m / min, 0.5m / min, 0.6m / min, 0.75m / min, 0.85m / min, 1.2m / min , 1.6m / min, 1.9...

Embodiment 3

[0037] This embodiment provides a method for treating flue gas from a rare earth electrolytic cell, which is implemented in the device for treating flue gas from a rare earth electrolytic cell in the above embodiment 1, see figure 1 , the method specifically includes the following steps:

[0038] (1) The flue gas produced in the upper part of the rare earth electrolytic cell 11 is collected into the smoke exhaust pipe 10, and the flow rate of the fan 4 is controlled to 3400m 3 / h, the power is 4.3kW, the total pressure is 2300Pa, which can reduce the temperature of the flue gas in the exhaust pipe 10 before entering the bag filter 1 to 160°C, and the cooled flue gas enters the bag filter 1, and the filter bag The effective area is 55 square meters, the material of the filter bag is Flumes, the effective wind speed of the filter bag is 0.6m / min, and the processing air volume is 2300m 3 / h, and adopts the pulse cleaning system program combining the fixed difference pressure con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com