Side biological treatment process for processing sludge-digestion liquid by adopting SNAD-MBBR technology as core

A sludge digestion solution and core treatment technology, applied in the field of environmental engineering, can solve the problems affecting the start-up speed and bacterial activity of the anammox reactor, the long time of sludge doubling, and the limitation of wide application, etc., to maintain long-term stable operation , Improve oxygen utilization rate, low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

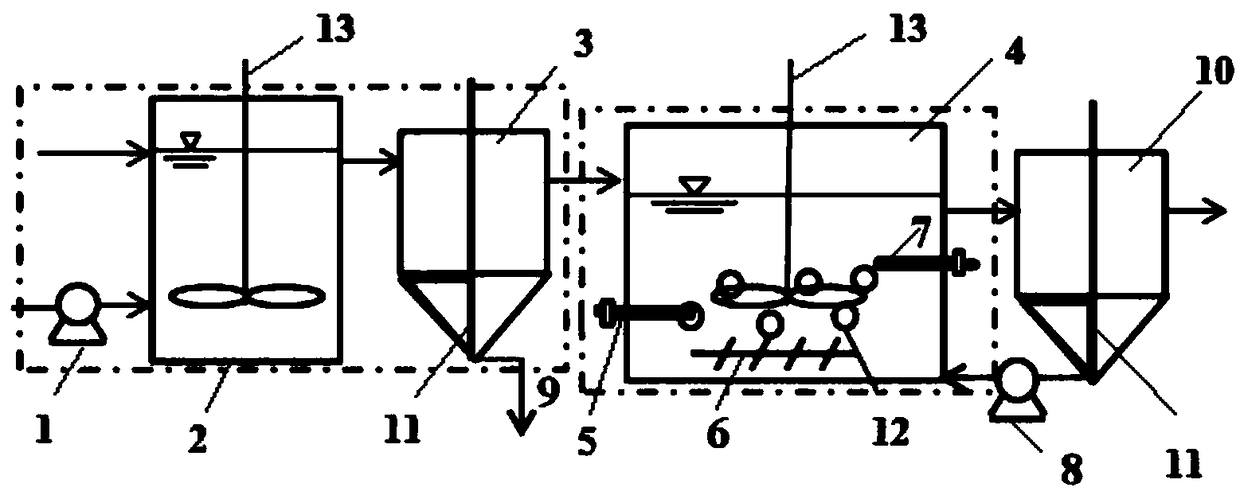

[0020] The side biological treatment system of the sludge digestion liquid includes the dosing pump 1, the coagulation sedimentation tank 2, the primary sedimentation tank 3, the SNAD-MBBR unit 4 and the secondary sedimentation tank 10 connected in sequence, in the coagulation sedimentation tank 2 An agitator 13 is installed inside to mix the coagulant and the sludge digestion liquid. The top of the primary sedimentation tank 3 is provided with an overflow weir, and the bottom is in the shape of a cone. A mud scraper 11 is provided in the primary sedimentation tank 3. At the bottom of the primary sedimentation tank 3, there is a sludge discharge pipeline 9 used to discharge the sludge separated by the mud scraper 11 out of the primary sedimentation tank 3. The effluent from the primary sedimentation tank 3 overflows to the SNAD-MBBR unit 4, where 4 is equipped with heater 5, at the bottom of SNAD-MBBR unit 4 is equipped with perforated aeration pipe 6, inside SNAD-MBBR unit 4 is...

Embodiment 2

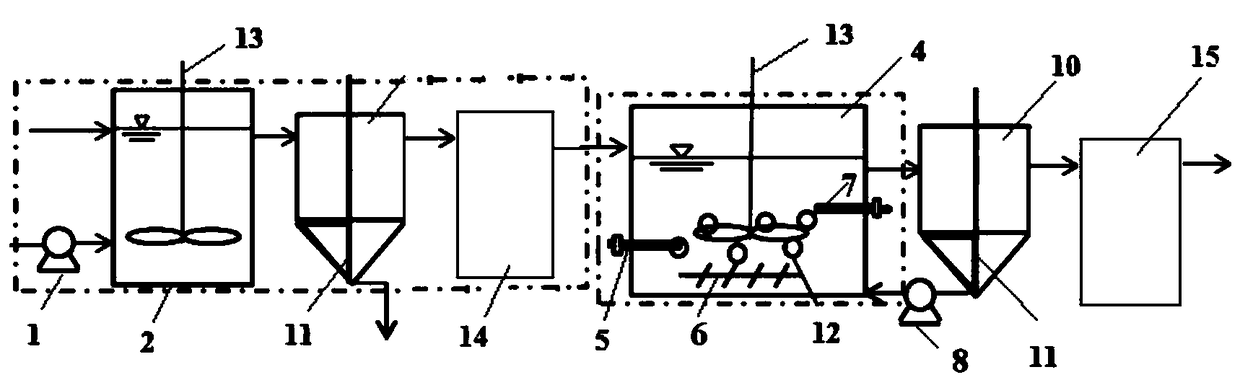

[0027] The side biological treatment system of the sludge digestion liquid, including the dosing pump 1, the coagulation sedimentation tank 2, the primary sedimentation tank 3, the collection well A 14, the SNAD-MBBR unit 4, the secondary sedimentation tank 10 and the collection well B connected in sequence 15. The sludge digestion liquid is stored in the digestion liquid storage tank, and the sludge digestion liquid flows into the coagulation sedimentation tank 2 through the pipeline, and the coagulation sedimentation tank 2 is equipped with a stirrer 13 for mixing the coagulant and the sludge Digestion liquid, the top of the primary sedimentation tank 3 is provided with an overflow weir, and the bottom is in the shape of a cone. A mud scraper 11 is provided in the primary sedimentation tank 3, and a mud drain pipeline 9 is provided at the bottom of the primary sedimentation tank 3 for The sludge separated by the scraper 11 is discharged out of the primary sedimentation tank 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com