Aquamicrobium defluvii active filler and preparation method thereof

An active filler and water microbacteria technology, applied in the field of environmental management, can solve the problems of slow startup of bioreactors, long microbial adaptation period, and difficulty in attaching microorganisms, and achieve the effects of small resistance, short adaptation period, and shortened start-up period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0042] Example 1: A water microbial active filler for removing sulfur-containing malodorous substances and its preparation method.

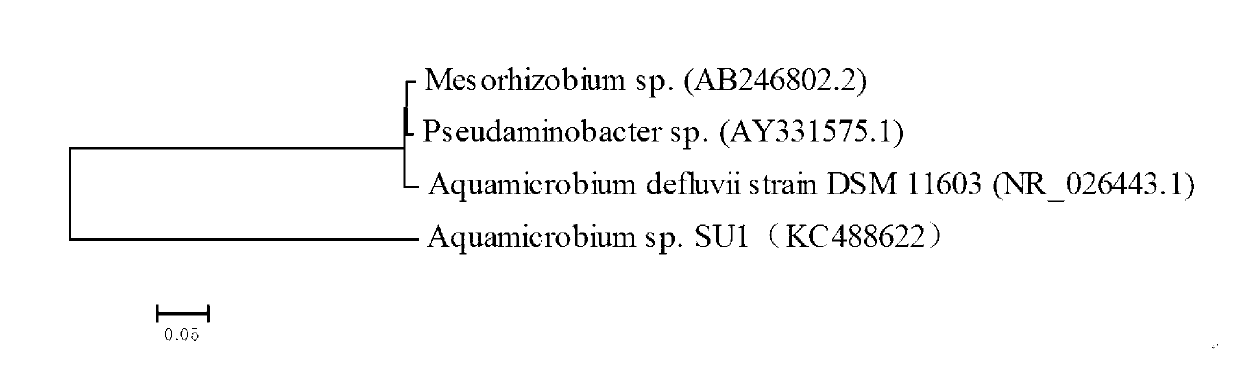

[0043] The Aquamicrobium defluvii active filler is attached with a suspension of Aquamicrobium defluvii SU1; the preservation number of Aquamicrobium defluvii SU1 is CGMCC No.7399;

[0044] The filler is a polyurethane foam block.

[0045] The packing density is 0.8kg / m 3 , the porosity is 86%, the particle size is 20mm;

[0046] The microorganisms are attached to the polyurethane foam block in the form of bacterial suspension;

[0047] The mass ratio of the microbial suspension to the polyurethane foam block is 200:10.

[0048] The thalline concentration of the water micro-bacteria SU1 in the described water micro-bacteria active filler is greater than 10 6 CFU / g (活性填料) .

[0049] The preparation steps of the described water micro-bacteria active filler are as follows:

[0050] (1) Slant surface culture: culture and prepare the slant stra...

example 2

[0060] Example 2: A water microbial active filler degrades H 2 S gas application.

[0061] Aquamicrobium defluvii (Aquamicrobium defluvii) SU1 (CGMCC No.7399), the bacterial agent prepared by this bacterium has a gas flow rate of 1.0-50m 3 / h, residence time 1-3min, temperature 20-37℃, hydrogen sulfide concentration 0.1-50mg / m 3 , methyl mercaptan 0.1-20mg / m 3 , The degradation efficiency of hydrogen sulfide, methyl mercaptan and other sulfur-containing odorous substances can reach more than 85%. It can be used to purify the gas of sulfur-containing and odorous substances, and solve the problem of odor pollution caused by sewage, sludge treatment, garbage treatment and composting.

[0062] The use of water micro-bacteria active fillers for odor gas treatment, especially in the degradation of H 2 For the application of S gas, the specific steps are as follows:

[0063] (1) Put the water micro-bacteria active filler loaded with water micro-bacteria SU1 in a container, and p...

example 3

[0067] Example 3: Use effect experiment (use the filler in Example 1 for the following gas treatment).

[0068] (1) Treat the sulfur-containing malodorous gas escaped from the sludge sedimentation tank of the sewage plant, and the gas flow rate is 35m 3 / h, put the water micro-bacteria active filler described in example 1 into it, the residence time is 1~3mins, operate under the room temperature condition. The intake concentration of hydrogen sulfide is: 8.32mg / m 3 , the output gas concentration is 0.03mg / m 3 , which is lower than the emission standard of odorous pollutants formulated by the state, and the removal rate reaches 99.6%.

[0069] (2) Put the water micro-bacteria active filler described in example 1 into it for processing the sulfur-containing malodorous gas that sludge composting produces, the concentration of hydrogen sulfide and ethanethiol is respectively 15.4mg / m 3 and 1.67mg / m 3 , the gas flow rate is 70m 3 / h, the residence time is 1-3mins, operating at r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com