Regeneration technology simultaneously achieving dry desulfurization, denitrification and demercuration by means of formula adsorbent

An adsorbent and formula technology, which is applied in the field of devices adopting formula-type adsorbent recycling and regeneration technology, can solve the problems of large investment in equipment cost, secondary pollution of waste liquid, and rare process methods, so as to save investment cost and reduce Operating cost and the effect of enhancing recycling utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Grind the columnar active coke to 150 mesh, wash the screened active coke powder with deionized water three times, dry it in an oven at 110°C for 12 hours, and store it in a drying dish for use.

[0064] Will Fe 3 o 4 3 g, 90 mL of toluene and 10 mL of 3-mercaptopropyltrimethoxysilane (3-MPTS) were mixed and stirred, and the resulting suspension was placed in an oven and dried at 25°C to form a white solid precipitate. The precipitate from the above steps was mixed with 90 mL of distilled water and Na 2 SiO 3 Mix and stir 1mL, then separate and remove the solution with a magnet, wash twice with deionized water to obtain Fe 3 o 4 Silicon coating (DSLC-Fe 3 o 4 ) 4g.

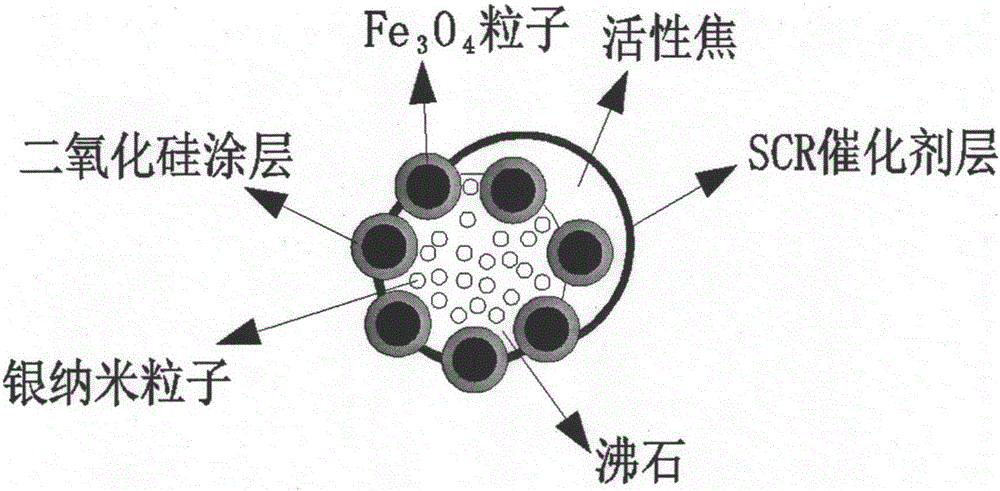

[0065] Zeolite 6g is dispersed in toluene 90mL, the Fe of above-mentioned step 3 o 4 Add 4 g of the silicon coating to toluene and stir, alternately wash twice with a certain amount of ethanol and distilled water to remove the toluene, heat the resulting solid at 300° C. for 1 hour, and grind it i...

Embodiment 2

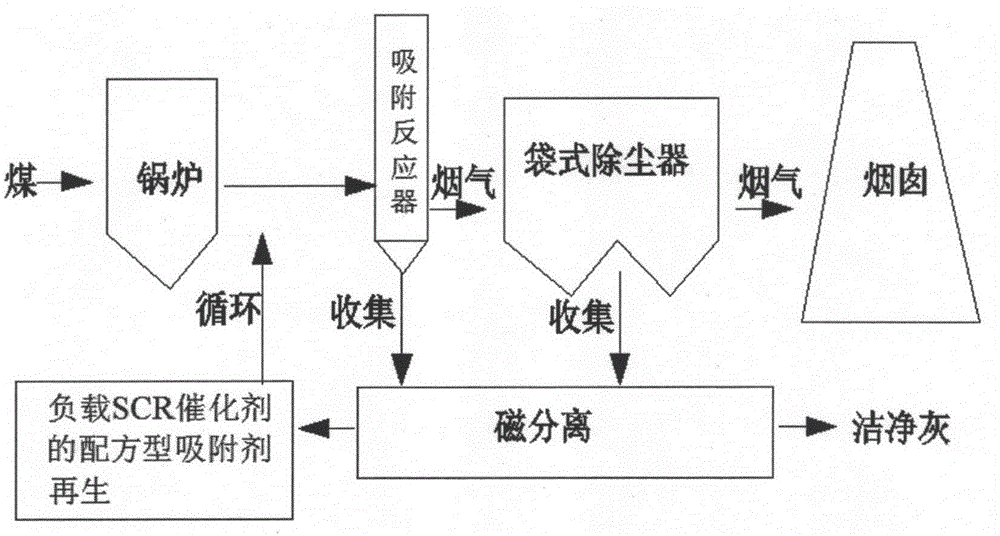

[0069] The regeneration process system of the formula type adsorbent of the present invention simultaneously dry desulfurization, denitrification and mercury removal includes three parts: an adsorber reaction system, a bag filter purification system, and an adsorbent regeneration cycle system.

[0070] The specific process is as figure 2 As shown, the coal-burning flue gas first enters the reaction chamber through the bottom inlet of the adsorption reactor and fully reacts with the formula-type adsorbent prepared in Example 1 sprayed on the top, and the Hg in the flue gas 0 Trapped by silver nanoparticles on the surface of the adsorbent, NO x by the SCR catalyst via NH 3 catalytic reduction to N 2 , SO 2 Physically adsorbed by activated coke, in the bag filter, the adsorbent carried by the flue gas will form an adsorption layer on the surface of the filter bag, and the Hg 0 , SO 2 , NO x Secondary adsorption, the flue gas after adsorption is discharged from the chimney....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com