Mixing uniformity detecting device and method for water-containing materials

A technology of mixing uniformity and detection device, which is applied in the direction of measuring device, sampling device, material weighing, etc., can solve the problem of inability to realize online detection of the mixing uniformity of pellet raw materials, inability to accurately judge the mixing uniformity of pellet raw materials, and fuzzy balls. problems such as the mixing degree of the raw materials in the agglomeration, to achieve the effect of easy transportation and installation, easy handling, and low driving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

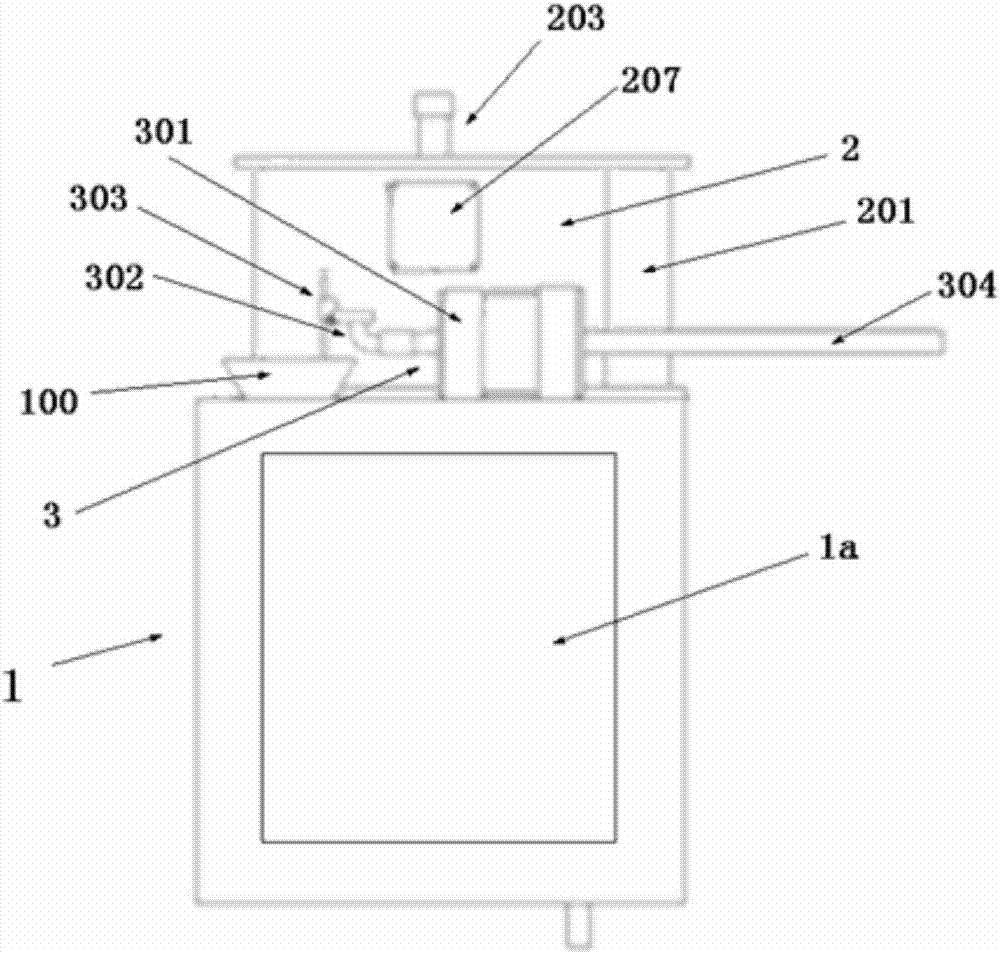

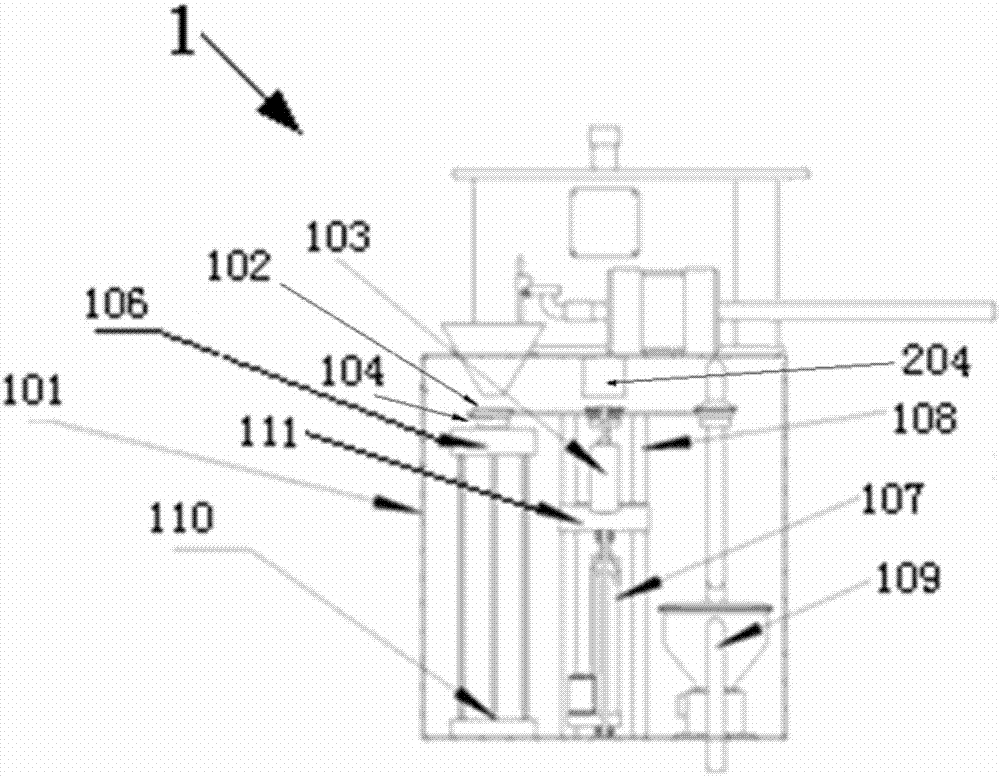

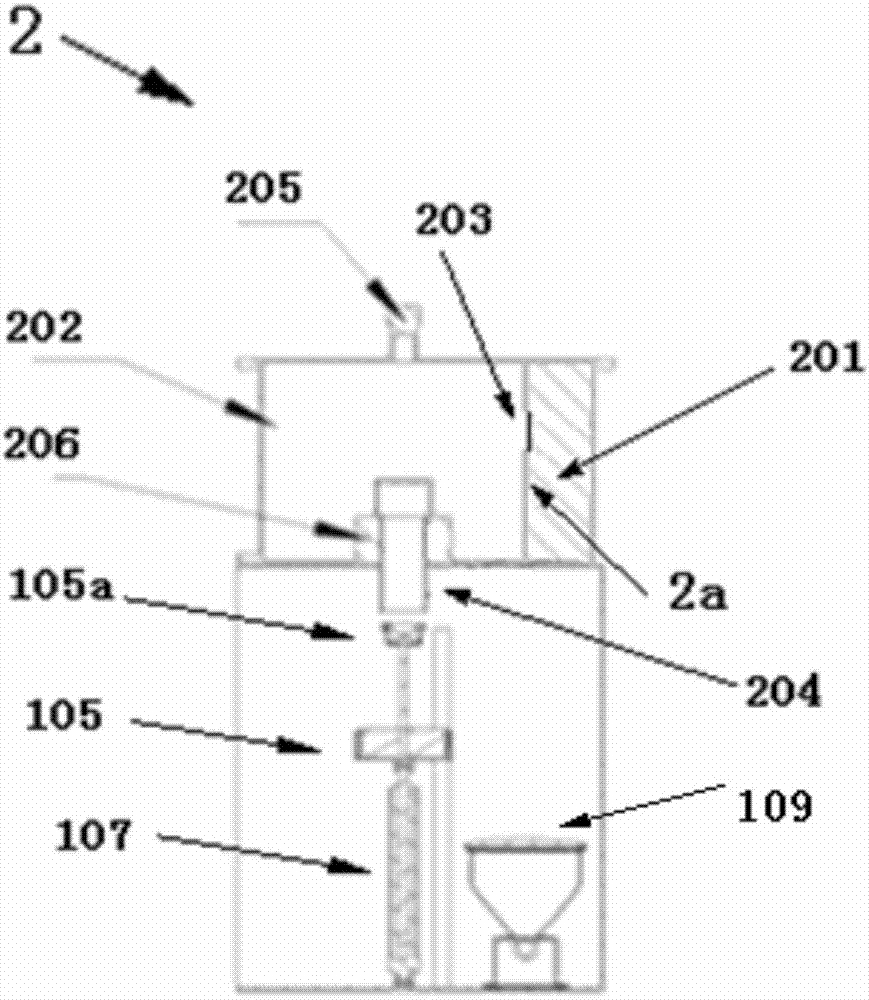

[0071] like figure 1 , a pellet raw material mixing degree detection device, including a sampling system 3, station switching and unloading system 1, microwave rapid drying system 2. The sampling system 3 is installed at the front end of the upper part (top cover) of the station conversion and unloading system 1, and the microwave rapid drying system 2 is installed at the rear end of the upper part (top cover) of the station conversion and unloading system 1. The sampling system 3 Input the material samples to be tested into the station conversion and unloading system 1 through the feeding funnel 100, and the microwave rapid drying system 2 communicates with the station conversion and unloading system 1 through the microwave cut-off pipe 204 as the sample lifting channel. Wherein the station conversion and unloading system 1 has at least three stations: feeding position A, microwave drying position B and unloading position C, and the rotary mechanism 103 of the station convers...

Embodiment 2

[0076] Repeat Example 1, except that the axis of the rotating mechanism is the apex of the angle, and the included angles between the three stations are 90°, 120° and 150° respectively.

Embodiment 3

[0078] A method for detecting the mixing degree of pellet raw materials, comprising the steps of:

[0079] 1) After the sampling spoon 302 picks up the material from the belt feeding place of the belt conveyor, it is driven by the linear motor 301 to recycle, and the scraper brush 303 scrapes off the material in the sampling spoon 302, and the sample material flows into the feeder along with the feeding funnel 100 Inside the sample box 102 made of quartz glass supported by the rotating mechanism 103 at position A; the first lifting device 106 drives the first weighing device 104 to rise vertically to support or hold the sample box 102 for the first weighing After the first weighing is completed, the first lifting device 106 drives the first weighing device 104 to descend vertically, and the weighed sample box 102 is supported by the rotating mechanism 103 again;

[0080] 2) The rotary mechanism 103 transfers the weighed sample box 102 from the feeding position A to or rotates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com