New technique for refining filler of calcium carbonate from lime mud

A calcium carbonate and new process technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of high processing cost, high equipment investment, and no large-scale production, and achieve the effect of simple production process and flexible process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

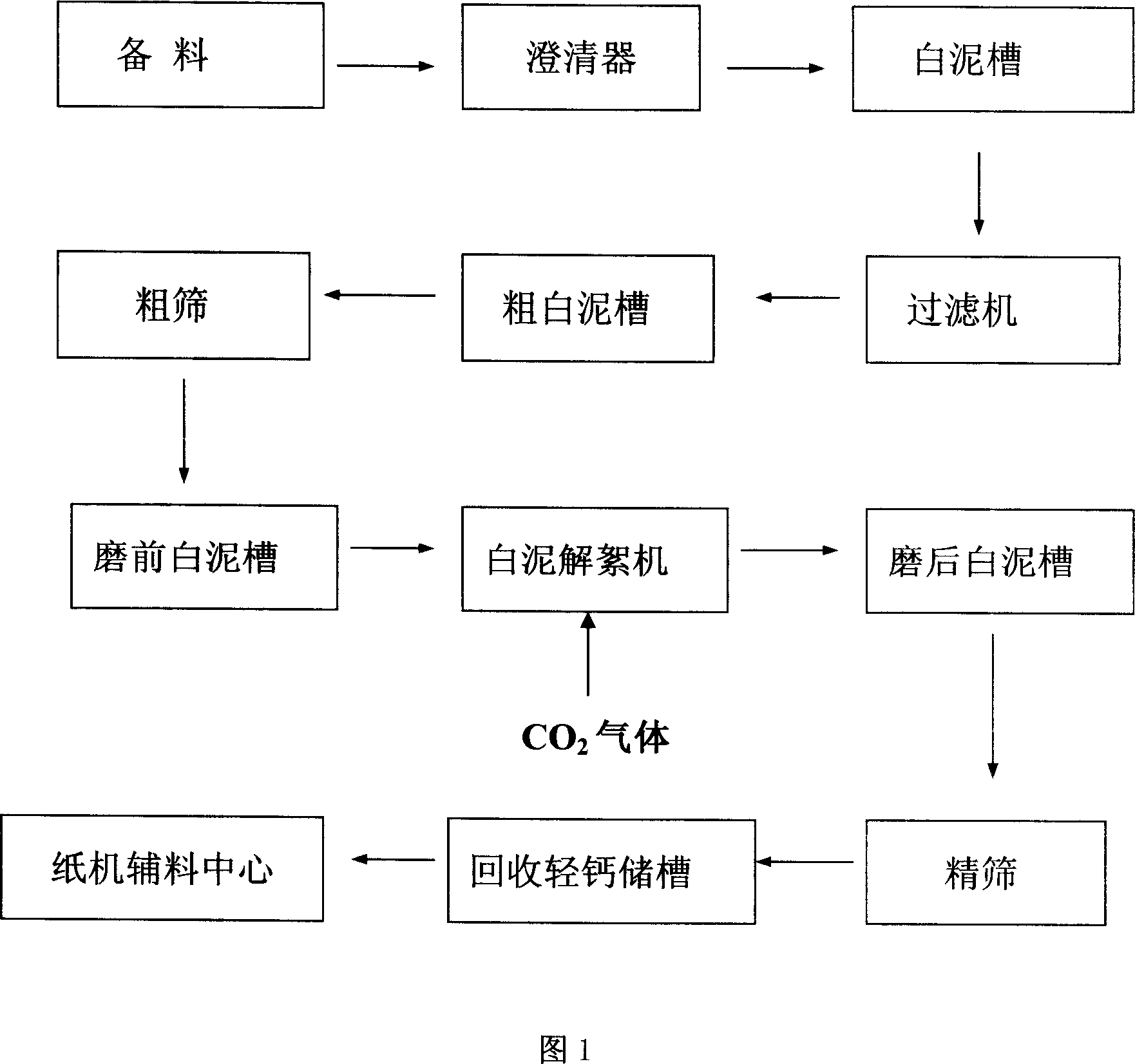

[0021] As shown in Figure 1, the white mud from the causticizing process is sent to the clarifier for clarification and washing, and after clarification, it is pumped into the white mud tank with a membrane pump, and the white mud concentration is adjusted to 20% by stirring. The white mud slurry is sent to the white mud pre-hanging washing machine, and the dry mud degree of the mud is 55%. The white mud falls into the coarse white mud tank, and the water is heated to dilute to 18%. The clear liquid is sent for alkali recovery, and the residual alkali is recovered. Then send the coarse white mud tank white mud to the first-stage 100-mesh rotary vibrating screen to remove large particles of coarse slag. Preliminary removal of incompletely burned matter, coal particles, furnace ash, carbon black, carbon particles, oil fume and other small impurities in the lime mud. The white mud enters the white mud tank before grinding, and then sends the white mud into the deflocculation mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com