Coking waste water treatment method and A / O technology apparatus

A technology for coking wastewater and treatment methods, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. problems, to improve the biological denitrification capacity and effect, the effect of complete cracking is good, and the effect of improving the treatment effect is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

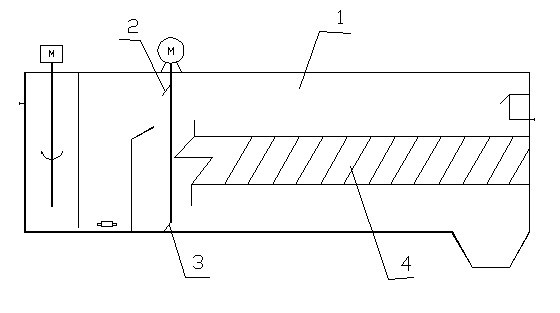

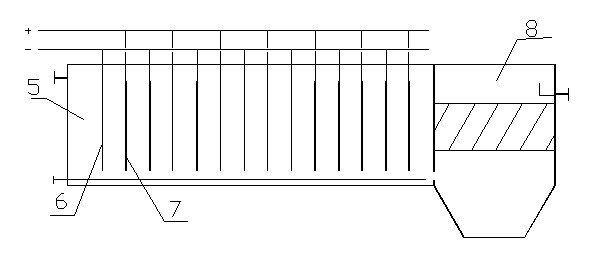

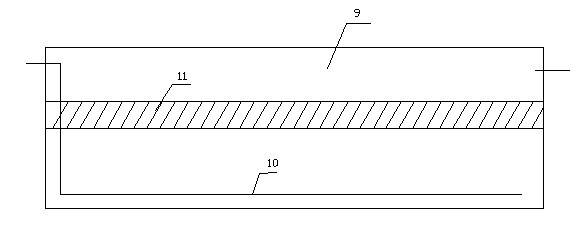

[0029] Example 1: A certain coking wastewater: COD=8000mg / l, NH3 -N=450mg / l, color=350 times; SS=120mg / l; oil=25mg / l. The treatment is carried out in sequence according to the pretreatment of physical and chemical oil removal, suspended solids, etc. → electrode energization, aerobic strong electrolysis, anaerobic biological hydrolysis acidification, and biological oxidation in the same pool, nitrification-denitrification (A / O).

[0030] First, adjust the pH of coking wastewater to 6.5-7.5, add polyaluminum chloride flocculant at a concentration of 6ppm and mix evenly, and send it to the integrated air flotation device 1 to separate light and heavy oil and suspended solids. The effluent COD=7800mg / l, NH 3 -N=450mg / l, chroma=320 times, SS=60mg / l, oil=0.5mg / l. Then enter the multi-electrode aerobic strong electrolytic cell 5 (aeration soda water ratio 5:1), voltage U=18V, current I=67A, after electrolysis for 2 hours, COD=4800mg / l, NH 3 -N=380mg / l, chromaticity=120 times, SS=360...

Embodiment 2

[0035] Example 2: A certain coking wastewater, COD=7500mg / l, NH 3 -N=350mg / l, chromaticity=350 times, SS=120mg / l, oils=25 mg / l; treatment process and used device are as embodiment 1.

[0036] Integrated air flotation device 1 treats effluent; COD=6700mg / l, NH 3 -N=300mg / l, chromaticity=320 times, SS=60mg / l, oil=0.5mg / l; treated water after aerobic strong electrolysis (steam water ratio 5:1, voltage U=18V, current I= 67A, electrolysis time 2 hours); COD=4200mg / l, NH 3 -N=280mg / l, chromaticity=120 times, SS=360mg / l, water after precipitation: COD=4200mg / l, NH 3 -N=280mg / l, chromaticity=120 times, SS=80mg / l; effluent after hydrolysis and acidification treatment for 18 hours: COD=2600 mg / l, NH 3 -N=210 mg / l, chromaticity=80 times, SS=60 mg / l; biological oxidation, nitrification-denitrification tank treatment in the same tank (aeration for 2 hours, forced circulation for 1.5 hours, static sedimentation for 30 minutes, decanting , add 25% NaOH3ppm, glucose 2ppm) during aeration)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com