Multi-channel pure silicon carbide film with asymmetric structure and preparation method for multi-channel pure silicon carbide film

A technology of structural silicon carbide membrane and asymmetric structure, applied in the field of inorganic membrane separation materials and membrane separation materials, can solve the problems of high sintering temperature of pure silicon carbide membrane, low purity of silicon carbide filter material, insufficient mechanical strength, etc. The effect of reducing the number of membrane casings and seals, flexible flow speed and flow time, and increasing filtration throughput and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

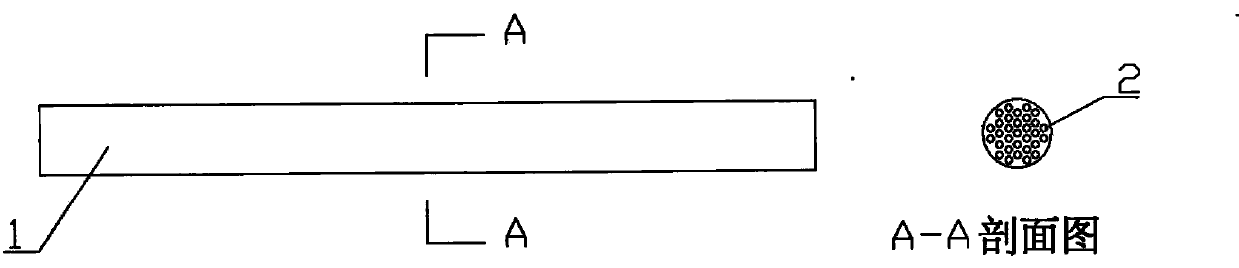

[0036] Blend 50-100μm silicon carbide particles, polysiloxane, carboxymethyl cellulose, phenolic resin, and polyethyleneimine in toluene at a mass percentage ratio of 65:12:19.5:3:0.5, and the toluene content accounts for the total 30wt% of the weight, after being mechanically stirred, ball milled for 0.5 hours to get a thick slurry, and then put into the mud mill to squeeze and knead for 30min to form a more evenly mixed slurry with good plasticity. Put the above slurry into the extruder. The head of the extruder adopts a 31-hole multi-channel mold with an outer circle and an inner circle. The extrusion pressure is controlled at 5MPa, the extrusion speed is 10mm / s, and the exit of the extruder is dried by infrared. The device quickly dries and finalizes the shape, adopts a high-temperature resistant graphite tray to accept the embryo body, and controls the extrusion length of the embryo body to 500mm; the preliminary formed embryo body is transferred to the drying room for dry...

Embodiment 2

[0043] The difference from Example 1 is:

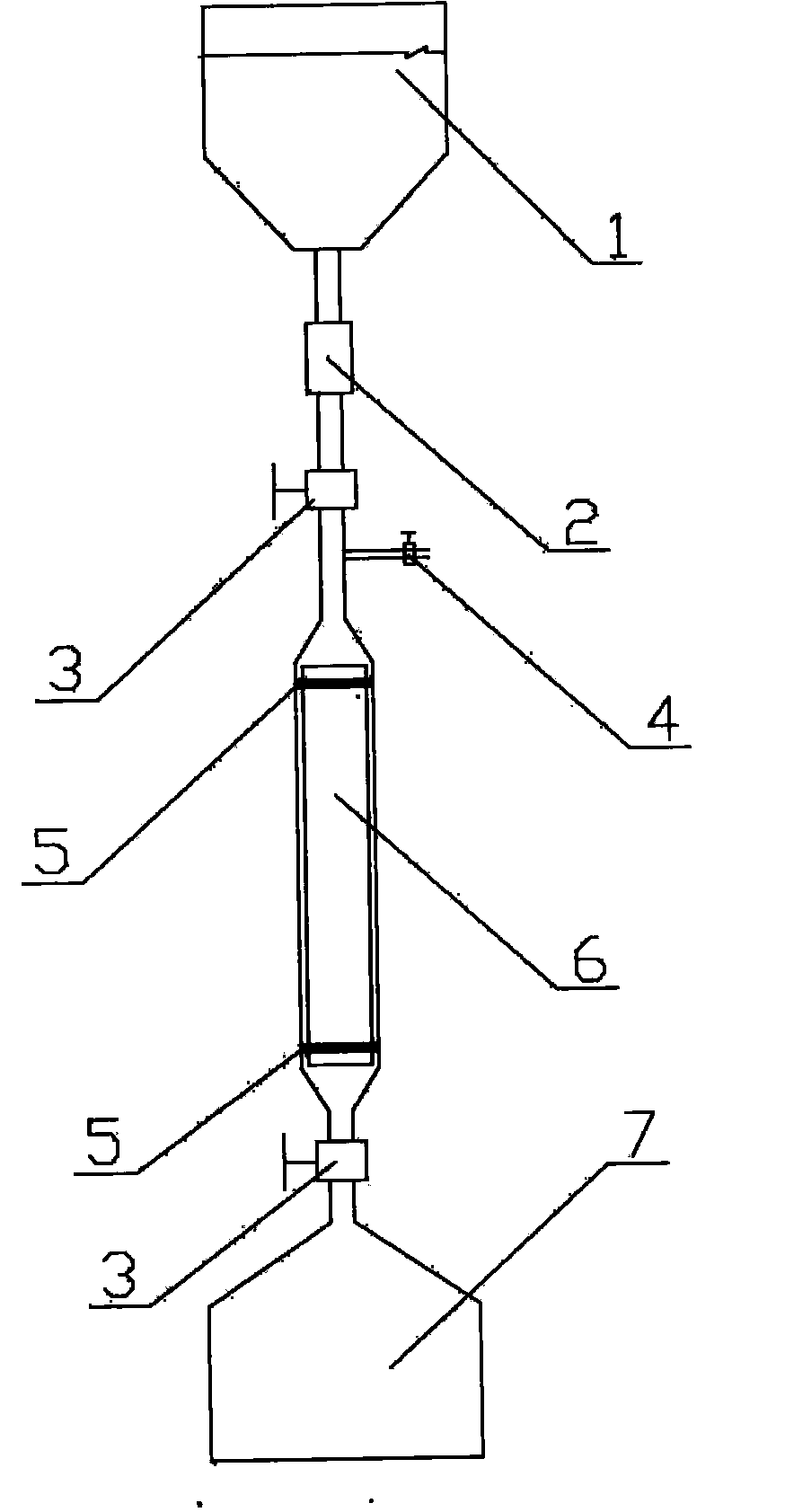

[0044] Mix 8μm silicon carbide particles with polysiloxane, carboxymethyl cellulose, polyethyleneimine and ethanol according to the mass percentage of 18:5:9:3:65, and stir them evenly to form No. 1 with good fluidity slurry. Put the multi-channel asymmetric structure pure silicon carbide film substrate into the vertical pipe, and the two ends of the substrate are sealed and fixed by the sealing ring, so that only the channels in the substrate are in contact with the slurry in the pipe, and then the slurry is separated by gravity. No. 1 slurry passes through the pipeline at a certain speed, and lasts for a certain period of time, and coats a layer of slurry on both ends of the substrate and internal passages to indicate the attached figure 2 ;The coated substrate is sintered in a sintering furnace after being dried. The heating rate is 6°C / min. First, the temperature is raised to 300°C and kept for 60 minutes; ; Then, the temperatur...

Embodiment 3

[0048] The difference from Example 1 is:

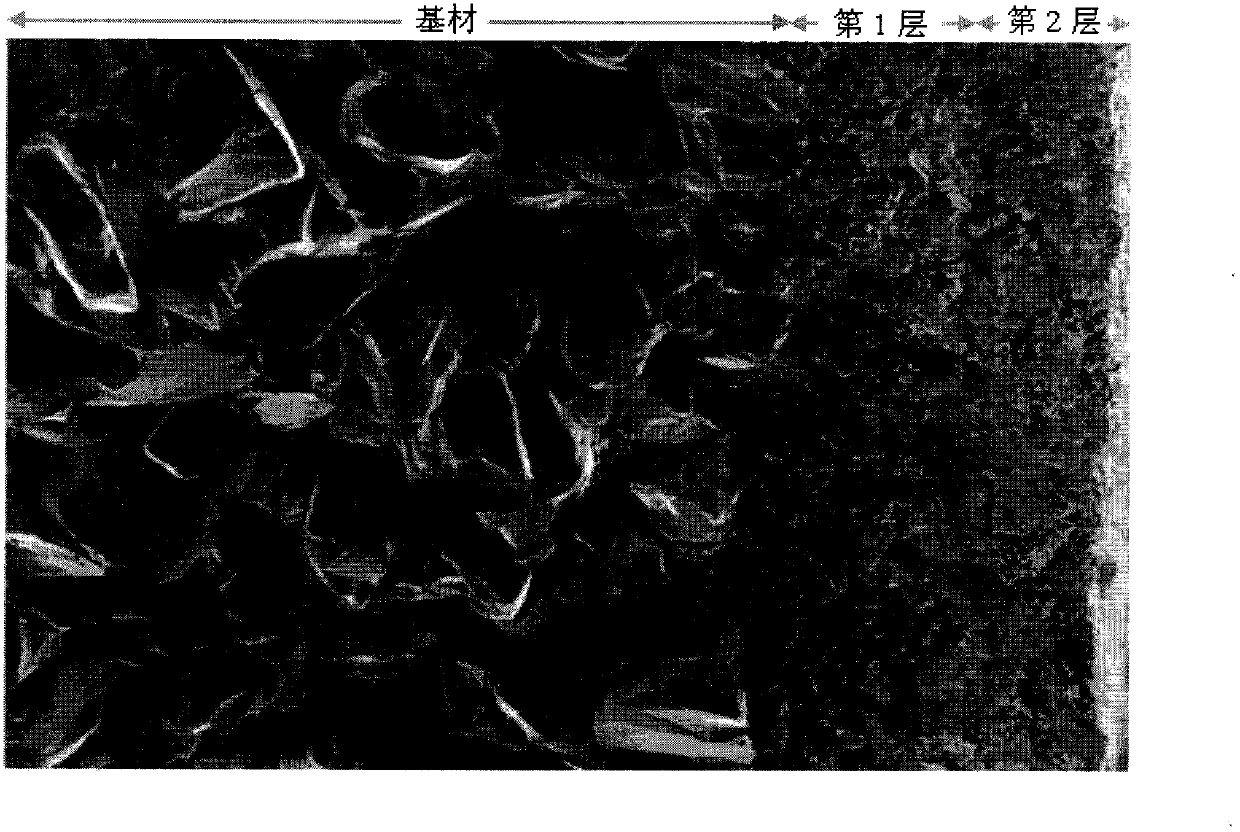

[0049] Mix 0.2μm silicon carbide particles with polysiloxane, carboxymethyl cellulose, phenolic resin, and polyvinylamine according to the mass percentage of 21:4:8:5:62, and stir them evenly to form a good fluidity No. 3 slurry; coated on the multi-channel asymmetric structure pure silicon carbide film of the 2-layer filter layer in Example 1, the coated substrate is sintered in the sintering furnace after being dried, and the heating rate is 4 ° C / min, first raise the temperature to 250°C, and keep it for 30 minutes; then raise the temperature to 800°C at a heating rate of 3°C / min, and keep it for 90 minutes; The furnace was naturally cooled to room temperature, and a multi-channel asymmetric structure pure silicon carbide membrane with three filter layers was obtained.

[0050] Such as figure 1. As shown, the multi-channel asymmetric structure pure silicon carbide membrane is a circular tubular membrane, the channel shape is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| bursting strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com