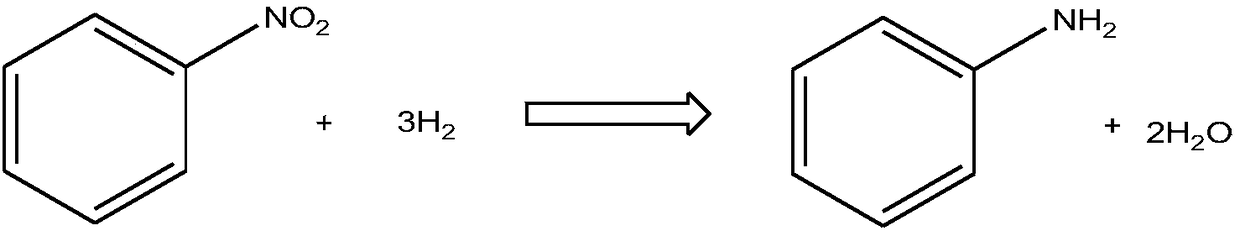

Method for preparing amine type products by hydrogenating nitro-compound

A technology for the preparation of nitro compounds and hydrogen, applied in the preparation of amino compounds, organic compounds, chemical instruments and methods, etc., can solve the problems of high content of by-products, achieve high selectivity, reduce back-mixing, and low probability of inactivation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

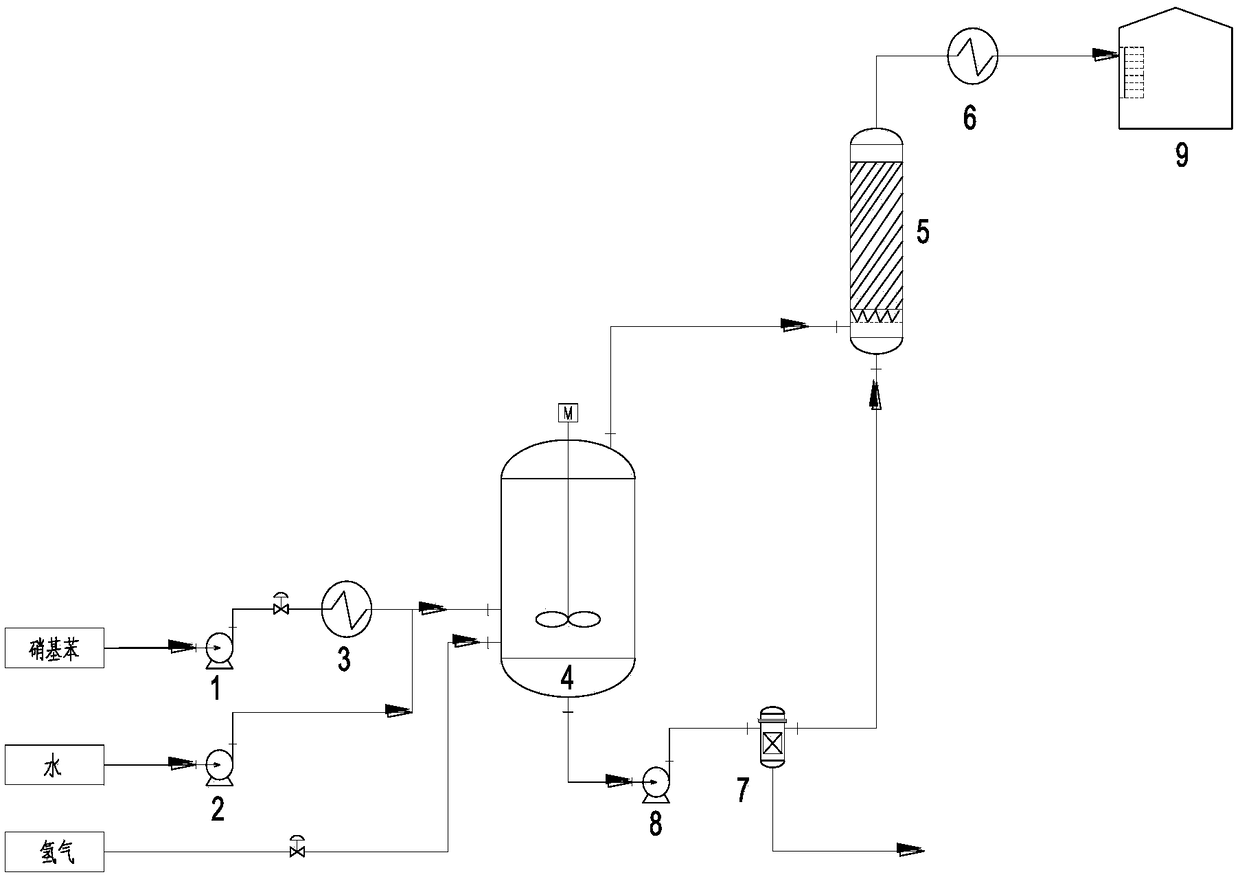

[0035] Nitrobenzene is sent into stirred tank reactor 4 by nitrobenzene delivery pump 1 after being heated by nitrobenzene preheater 3, flow 65kg / hr; Water is sent into stirred tank reactor 4 by water delivery pump 2, water flow 55kg / hr; hydrogen was passed into the stirred tank reactor 4, with a flow rate of 1664 mol / hr; a Pt / Pd catalyst loaded with activated carbon was used in the reactor, and the concentration was 1 wt %. At a pressure of 17 bar and a temperature of 200 °C, nitrobenzene and hydrogen react in a stirred tank reactor to generate aniline and water.

[0036] The gas phase of the stirred tank reactor is discharged to the fixed bed reactor 5 to continue the reaction, and the liquid material is extracted at the flow rate of 0.6 kg / hr at the bottom of the stirred tank. Then continue to react. A copper-zinc-aluminum alloy catalyst (referring to patent CN106000408A for preparation method) is used in the fixed bed, and the filling amount is 0.8kg, and the hydrogenati...

Embodiment 2

[0039] Nitrobenzene is sent into stirred tank reactor 4 by nitrobenzene delivery pump 1 after being heated by nitrobenzene preheater 3, flow 65kg / hr; Water is sent into stirred tank reactor 4 by water delivery pump 2, water flow 55kg / hr; hydrogen was passed into the stirred tank reactor 4, and the flow rate was 1617 mol / hr; the reaction kettle adopted a Pt / Pd catalyst loaded with activated carbon, and the concentration was 0.2 wt%. At a pressure of 17 bar and a temperature of 250 °C, nitrobenzene and hydrogen react in a stirred tank reactor to generate aniline and water.

[0040] The stirred tank reactor gas phase is discharged to the fixed bed reactor 5 to continue the reaction, and the liquid material is extracted at the flow rate of 2kg / hr at the bottom of the stirred tank. Continue to react, adopt and adopt copper-zinc-aluminum alloy catalyst in fixed bed (referring to patent CN106000408A for preparation method), catalyst loading amount is 0.8kg, continue hydrogenation re...

Embodiment 3

[0043] Nitrobenzene is sent into stirred tank reactor 4 by nitrobenzene delivery pump 1 after being heated by nitrobenzene preheater 3, flow 65kg / hr; Water is sent into stirred tank reactor 4 by water delivery pump 2, water flow 55kg / hr; hydrogen was passed into the stirred tank reactor 4, and the flow rate was 1902 mol / hr; the reaction kettle adopted a Pt / Pd catalyst loaded with activated carbon, and the concentration was 5wt%. At a pressure of 17 bar and a temperature of 160 °C, nitrobenzene and hydrogen react in a stirred tank reactor to generate aniline and water.

[0044] The stirred tank reactor gas phase is discharged to the fixed bed reactor 5 to continue the reaction, and the liquid material is extracted by the flow rate of 2kg / hr in the stirred tank. Reaction, adopts copper-zinc-aluminum alloy catalyst (preparation method with reference to patent CN106000408A) in the fixed bed, the catalyst loading is 0.8kg, continues hydrogenation reaction under pressure 17bar, inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com