Preparation method of porous silicon carbide ceramic support body

A porous silicon carbide and support technology, which is applied in ceramic products, chemical instruments and methods, sustainable biological treatment, etc., can solve the problems of hindering the development of silicon carbide ceramic technology, high brittleness of silicon carbide ceramics, and low purity of silicon carbide ceramics. , to avoid low product strength, high porosity, and ensure the effect of early mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of a porous silicon carbide ceramic support body, the specific steps are as follows:

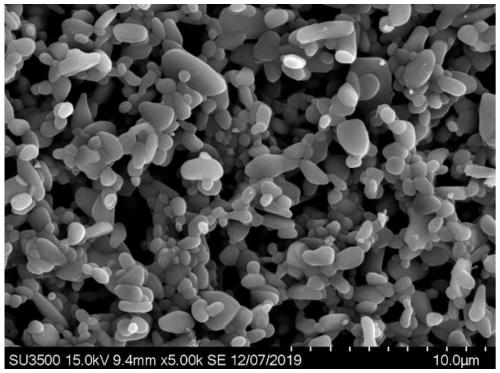

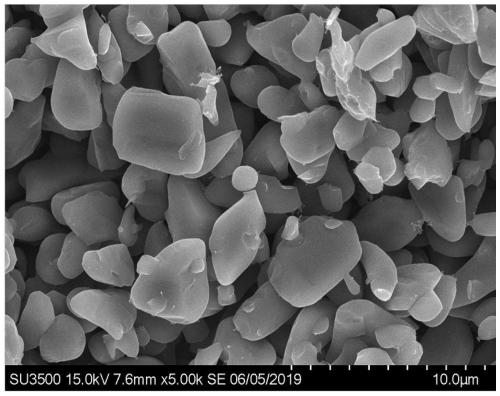

[0035] 1) Mix coarse silicon carbide and fine particle silicon carbide at a mass ratio of 90:10, stir evenly, and obtain mixed silicon carbide for use; mix methyl cellulose, tetramethylammonium hydroxide, and polyethyleneimine by Mix at a mass ratio of 1:1:0.8 to obtain a dispersant;

[0036] 2) Weigh each raw material according to the proportion, each raw material and its mass percentage are: mixed silicon carbide 65%, dispersant 1%, silicon dioxide powder 10%, foaming agent 1%, styrene-acrylic emulsion 23%;

[0037] 3) Add the weighed mixed silicon carbide, dispersant and silicon dioxide into the styrene-acrylic emulsion (13% of the total amount of raw materials) and stir to obtain a uniformly dispersed silicon carbide slurry; the weighed blowing agent and the remaining Add the styrene-acrylic emulsion solvent into the foaming machine and stir for 3 minutes; th...

Embodiment 2

[0042] A preparation method of a porous silicon carbide ceramic support body, the specific steps are as follows:

[0043] 1) Mix coarse silicon carbide and fine silicon carbide at a mass ratio of 93:7, stir evenly to obtain mixed silicon carbide for use; mix methyl cellulose, tetramethylammonium hydroxide, and polyethyleneimine by 1:1.2:1 mass ratio mixing, get dispersant;

[0044] 2) Weigh each raw material according to the proportion, each raw material and its mass percentage are: mixed silicon carbide powder 66%, dispersant 1%, silicon dioxide powder 8%, foaming agent 1%, styrene-acrylic emulsion solvent twenty four%;

[0045] 3) Add the weighed mixed silicon carbide, dispersant and silicon dioxide into the styrene-acrylic emulsion (12% of the total amount of raw materials) and stir to obtain a uniformly dispersed silicon carbide slurry; mix the weighed blowing agent and the remaining The styrene-acrylic emulsion solvent was added to the foaming machine and stirred for 5 ...

Embodiment 3

[0050] A preparation method of a porous silicon carbide ceramic support body, the specific steps are as follows:

[0051] 1) Mix coarse silicon carbide and fine silicon carbide at a mass ratio of 95:5, stir evenly, and obtain mixed silicon carbide for use; mix methyl cellulose, tetramethylammonium hydroxide, and polyethyleneimine by Mix at a mass ratio of 1:1:1 to obtain a dispersant;

[0052] 2) Weigh each raw material according to the proportion, each raw material and its mass percentage are: mixed silicon carbide powder 63%, dispersant 1.5%, silicon dioxide powder 11%, blowing agent 1.5%, styrene-acrylic emulsion solvent twenty three%;

[0053] 3) Add the weighed mixed silicon carbide, dispersant and silicon dioxide into the styrene-acrylic emulsion (11% of the total amount of raw materials) and stir to obtain a uniformly dispersed silicon carbide slurry; mix the weighed blowing agent and the remaining The styrene-acrylic emulsion solvent was added to the foaming machine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com