Flying-shear main-transmission gearwheel steel and preparation method thereof

A manufacturing method and a main transmission technology, applied in the field of rolling machinery, can solve the problems of difficulty in ensuring the uniformity of the hardened layer of the tooth surface, affecting the contact fatigue performance of the tooth surface, affecting the machining accuracy of the tooth shape, etc., so as to reduce harmful inclusions, The effect of avoiding tooth flank failure and improving load-carrying capacity and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] An existing bloom flying shear has been operating at full load under severe conditions such as high temperature, impact, and heavy load. The original 34Cr 2 Ni 2 Mo steel ring gear and No. 25 steel radial plate welded surface-hardened medium-hardened tooth surface (52-58HRC) large gear have been used for less than 2 years, and failure problems such as cracking at the welding part of the radial plate, severe wear and pitting of the tooth surface have occurred. Unable to continue using. In order to completely solve the problem of insufficient strength of the large gear and cracking of the welded part of the web, the large gear has been changed from the original welded structure to the integral structure.

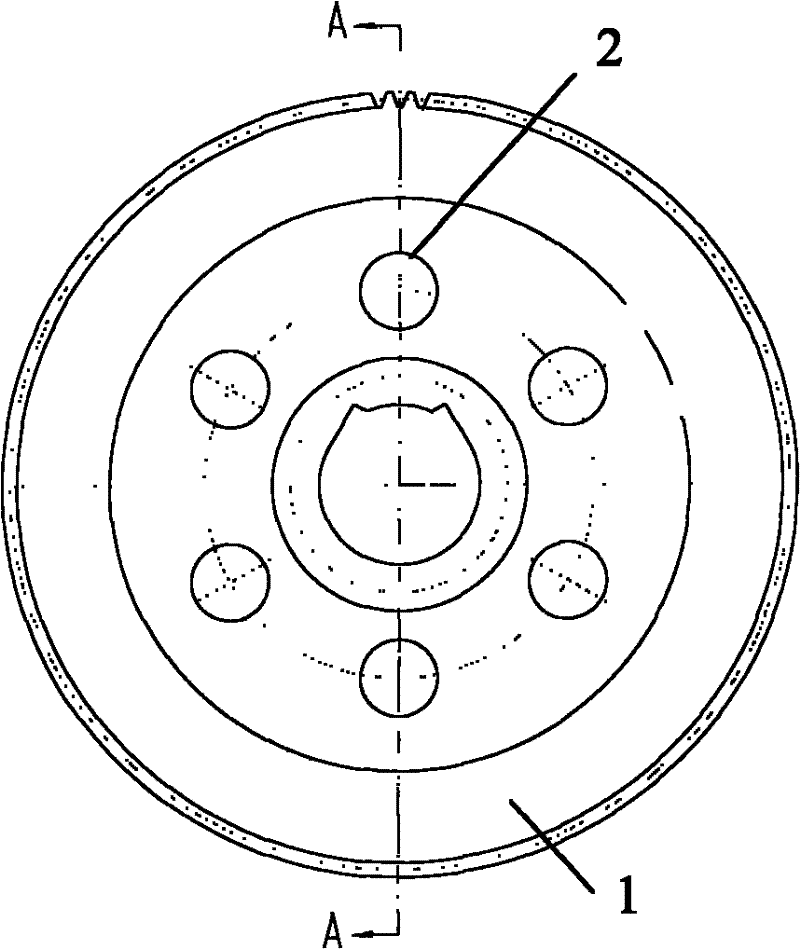

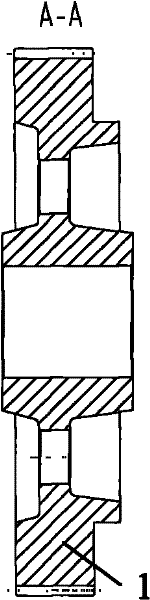

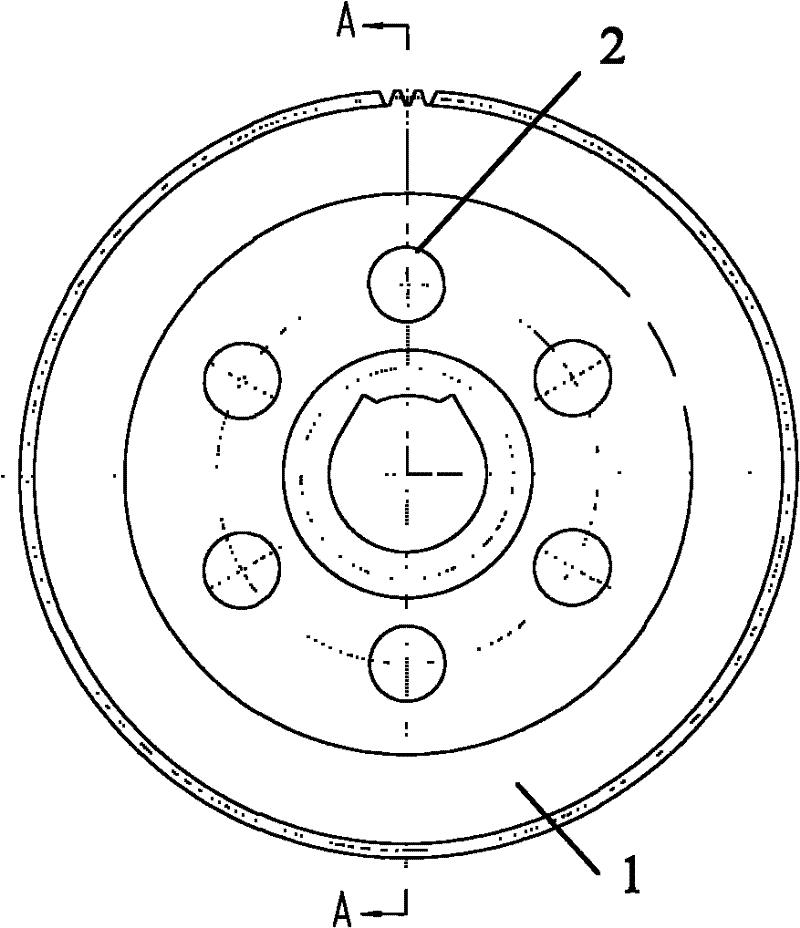

[0065] like figure 1 and figure 2 As shown, in order to reduce the weight of the large gear 1, the large gear adopts an inner concave structure, and six through holes 2 are processed along the circumferential direction of the gear in the inner recess; the inner hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com