Self-overlapping refrigeration system

A refrigeration system, self-cascading technology, applied in refrigerators, refrigeration and liquefaction, compressors with cascading work, etc., can solve the problems of slow cooling speed, high exhaust pressure and high exhaust temperature when starting up, and achieve Improve the cooling speed, reduce the system pressure, and reduce the exhaust pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

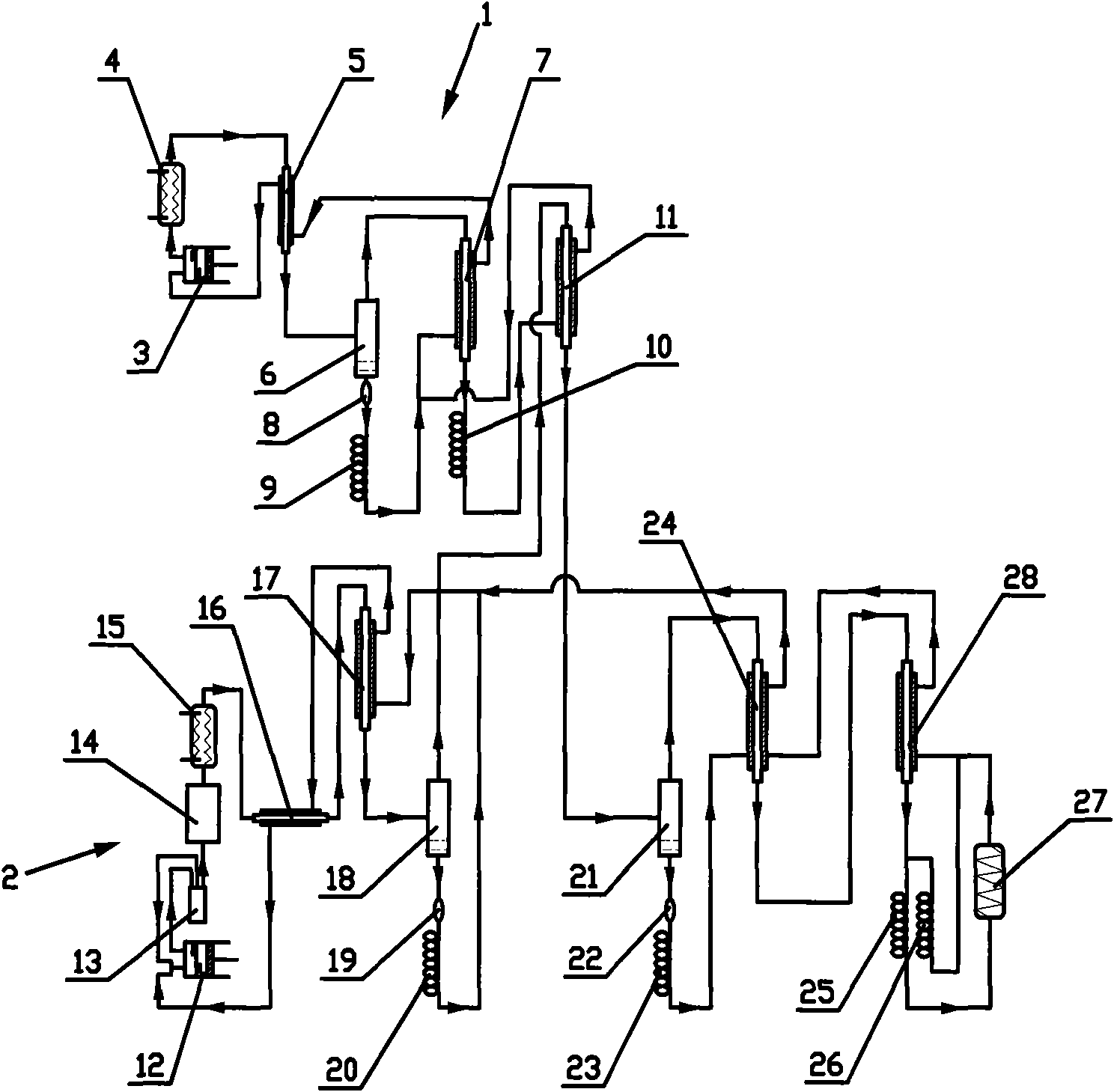

[0020] The figure shows the self-cascading refrigeration system according to the present invention, which includes a high-temperature self-cascading circuit 1 and a low-temperature self-cascading circuit 2 .

[0021] The high temperature stage compressor 3 compresses the mixed refrigerant to enter the high temperature stage condenser 4 . The refrigerating working medium releases heat in the high-temperature stage condenser 4, the high-boiling point refrigerating working medium is liquefied, and the low-boiling point refrigerating working medium is still gaseous, and enters the high-boiling point refrigerating working medium in the high-temperature stage regenerator 5 to further cool down and improve the condensation effect. After passing through the high temperature regenerator 5, the refrigerant enters the high temperature gas-liquid separator 6. As shown in the figure, the gas phase part in the refrigerant rises upward along the direction of the arrow in the figure and enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com