Manufacturing method of oversized continuous casting slab of nickel stainless steel

A manufacturing method and super-large-scale technology, applied in the field of metal material stainless steel smelting technology, can solve the problems of undetected continuous casting large round billets and blooms, super large cross-section nickel stainless continuous casting billets, difficulty in production, complex process parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Steel type: 022Cr19Ni10 (304L)

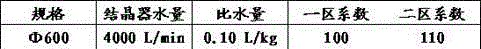

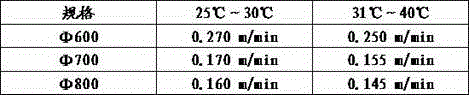

[0065] Furnace number: 15113052909, continuous casting slab finished product specification: Φ600mm.

[0066] Process flow: UHP→AOD→ (VD)→LF→continuous casting→finishing→packaging.

[0067] 1. Steelmaking process

[0068] (1) The actual chemical composition of 022Cr19Ni10 (304L) steel, see Table 10,

[0069] Table 10 Chemical composition of 022Cr19Ni10 (304L) steel

[0070]

[0071] ⑵Electric furnace process

[0072] Furnace loading capacity is 55 tons, and the furnace materials are selected from high-quality 300 series returned scrap steel, high-carbon ferrochrome, and nickel-containing pig iron. Among them, the amount of 300 series returned scrap steel is 35 tons, the amount of nickel-containing pig iron is 10 tons, and high-carbon ferrochrome is 8 tons; Tapping temperature (T): 1630°C, part of the high-carbon alloy material is used to adjust the composition when tapping; eccentric bottom tapping, slag tapping cannot be controlle...

Embodiment 2

[0100] Steel type: 022Cr17Ni12Mo2 (316L)

[0101] Furnace number: 15116012920; Specifications of the finished billet: 380*490mm.

[0102] Process flow: UHP→AOD→ (VD)→LF→continuous casting→finishing→packaging.

[0103] 1. Steelmaking process

[0104] (1) The actual chemical composition of 022Cr17Ni12Mo2 (316L) steel, see Table 14,

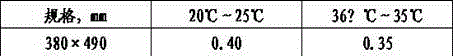

[0105] Table 14 Chemical composition of 022Cr17Ni12Mo2 (316L) steel

[0106]

[0107] ⑵ Electric furnace process

[0108] Furnace loading capacity is 53 tons, and the charge is selected from high-quality 300 series returned scrap steel, high-carbon ferrochrome, and nickel-containing pig iron. Among them, the amount of 300 series returned scrap steel is 40 tons, the amount of nickel-containing pig iron is 10 tons, and the amount of high-carbon ferrochrome is 5 tons; Tapping temperature (T): 1620°C, part of the high-carbon alloy material is used to adjust the composition when tapping; eccentricity is low for tapping, and slag tapping cannot be ...

Embodiment 3

[0137] Steel type: 06Cr19Ni10 (304)

[0138] Furnace number: 16114050446, continuous casting slab finished product specification: Φ600mm.

[0139] Process flow: UHP→AOD→ (VD)→LF→continuous casting→finishing→packaging;

[0140]1. Steelmaking process

[0141] ⑴ The actual chemical composition of 06Cr19Ni10 (304) steel is shown in Table 18.

[0142] Table 18 Chemical composition of 304 steel

[0143]

[0144] ⑵Electric furnace process

[0145] Furnace loading capacity is 54 tons, and the furnace materials are high-quality 300 series returned scrap steel, high-carbon ferrochrome, and nickel-containing pig iron, of which 35 tons of 300-series returned scrap steel, 10 tons of nickel-containing pig iron, and 9 tons of high-carbon ferrochrome are used; Tapping temperature (T): 1630°C, part of the high-carbon alloy material is used to adjust the composition when tapping; eccentric bottom tapping, slag tapping cannot be controlled; 5 minutes before tapping, reduce the oxygen inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com