Method for controlling bloom continuous casting dynamic soft-reduction pressure interval

A control method and soft reduction technology, which is applied in the field of bloom continuous casting soft reduction technology, can solve problems such as unsuitable welding, lower welding performance, and large randomness, so as to shorten the development cycle, optimize the reduction interval, and achieve application effects stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

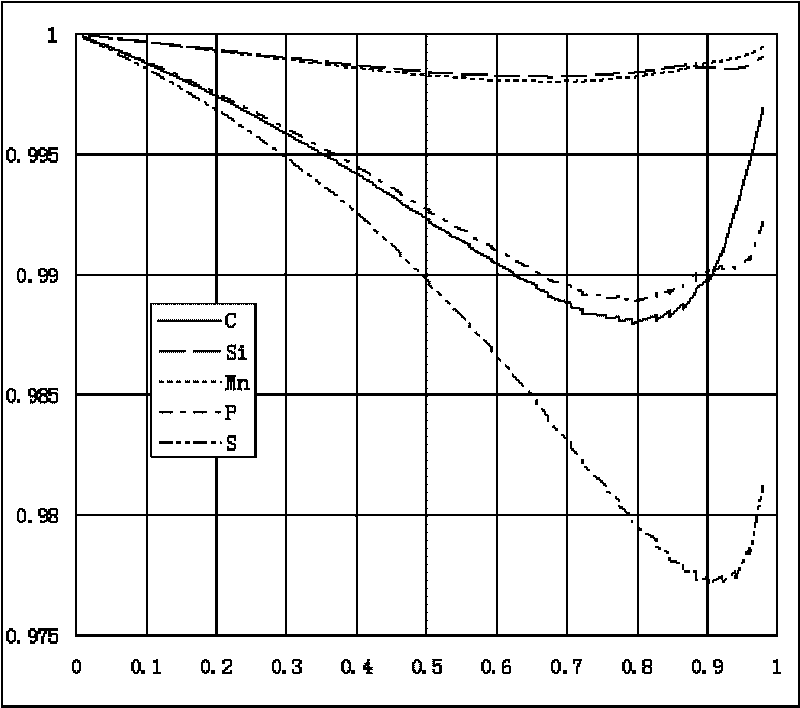

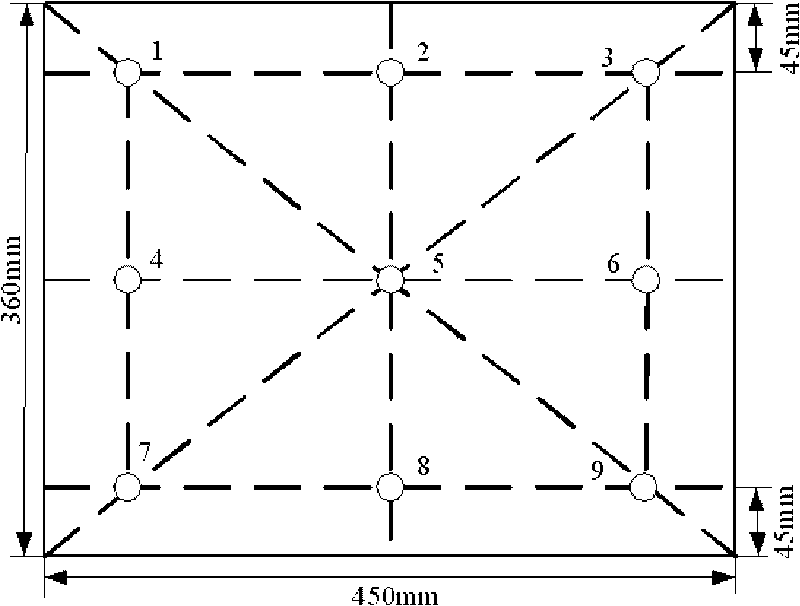

[0080] The slab is a high-strength weathering steel YQ450NQR1 slab with a cross-section of 360mm×450mm. The pouring superheat is 25°C, the casting speed is 0.6m / min, and the reduction range corresponds to the solid phase ratio of the slab center of 0.67-0.90. The weight percentages of solute elements of steel grades are shown in Table 1. Using a seven-stand rolling mill, when the reduction is 2mm, the minimum K of each solute element i The central solid fraction f at the corresponding section s,i opt and f s,Max opt , f s,Min opt As in Table 3, K i and each cross-section f of the slab s The corresponding relationship is as figure 1 , the horizontal axis is f s , the vertical axis is K i . After implementing the scheme, the carbon segregation index of the cross-section of the steel slab is improved from 0.90-1.09 to 0.94-1.05, and the carbon segregation index of the longitudinal section center is reduced from 1.04-1.14 to 1.02-1.09. The specific sampling points of t...

Embodiment 2

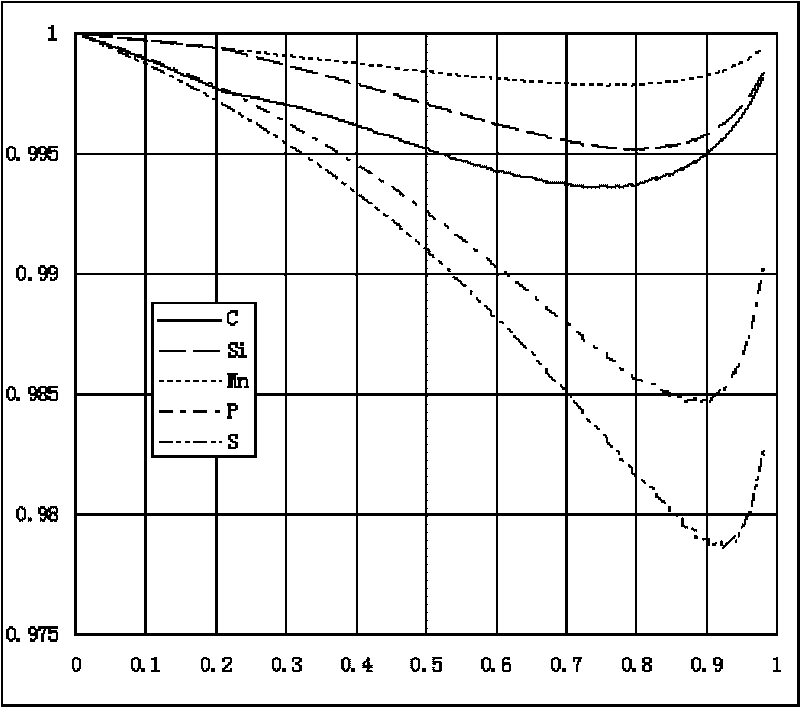

[0084] The billet is a billet of alloy structural steel 37Mn2 with a section of 360mm×450mm, the pouring superheat is 25°C, the casting speed is 0.6m / min, and the solid phase rate corresponding to the center of the billet is 0.72-0.92 in the reduction range. The weight percentages of solute elements of steel grades are shown in Table 2. Using a seven-stand rolling mill, when the reduction is 2mm, the minimum K of each solute element i The central solid fraction f at the corresponding section s,i opt and f s,Max opt , f s,Min opt As in Table 3, K i and each cross-section f of the slab s The corresponding relationship is as figure 2 , the horizontal axis is f s , the vertical axis is K i . After implementing the scheme, the carbon segregation index of the cross-section of the steel slab is improved from 0.87-1.12 to 0.91-1.07, and the carbon segregation index of the longitudinal section center is reduced from 1.06-1.19 to 1.04-1.09. The specific sampling points of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com