Production process for 48MnV round steel

A production process, 48mnv technology, applied in the field of metallurgical rolling, can solve the problems of easy leakage of steel slabs, the inability to control it, and the lack of improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

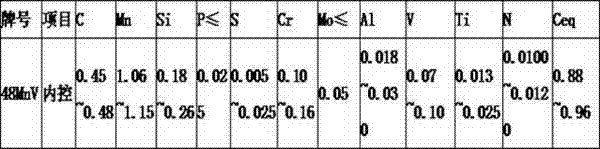

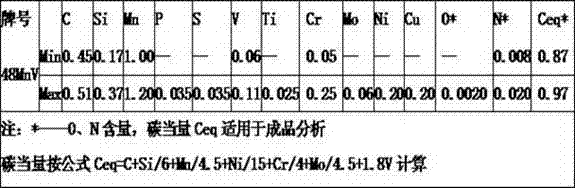

Image

Examples

Embodiment 1

[0059] Rolling number: B90196301, the cumulative reduction of this rolling number is 5mm during continuous casting, and two passes of large reduction are used during rolling, and the reduction of each pass is 80mm.

Embodiment 2

[0061] Rolling number: B00187901, the cumulative reduction of this rolling number is 5mm during continuous casting, and two passes of large reduction are used during rolling, and the reduction of each pass is 30mm.

[0062] After the sample was heated at (1000±5)°C for 30 minutes, and cooled to room temperature in still air, the data were better than those of the control sample, see Table 4.

[0063] Table 4

[0064] ReL, MPa Rm, MPa A,% Z,% Impact energy AKU2 J Require ≥500 ≥800-920 ≥13 ≥25 ≥32 B90196301 625 / 640 915 / 910 14.0 / 15.0 41.5 / 40.5 45 B00187901 615 / 635 925 / 915 15.5 / 15.5 40.1.0 / 42..0 47 Parallelization 580 / 575 890 / 880 13.5 35 36

[0065] The present invention adopts the continuous casting bloom dynamic light reduction technology during smelting, and adopts the large reduction rolling process during rolling. These two processes are superimposed and used in the production of non-quenched and tempered steel 48...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com