Control method of natural roll-gap thermal-contraction technique based on bloom

A control method and thermal shrinkage technology, applied in the field of billet continuous casting roll gap technology, to achieve the effect of improving center segregation and center porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

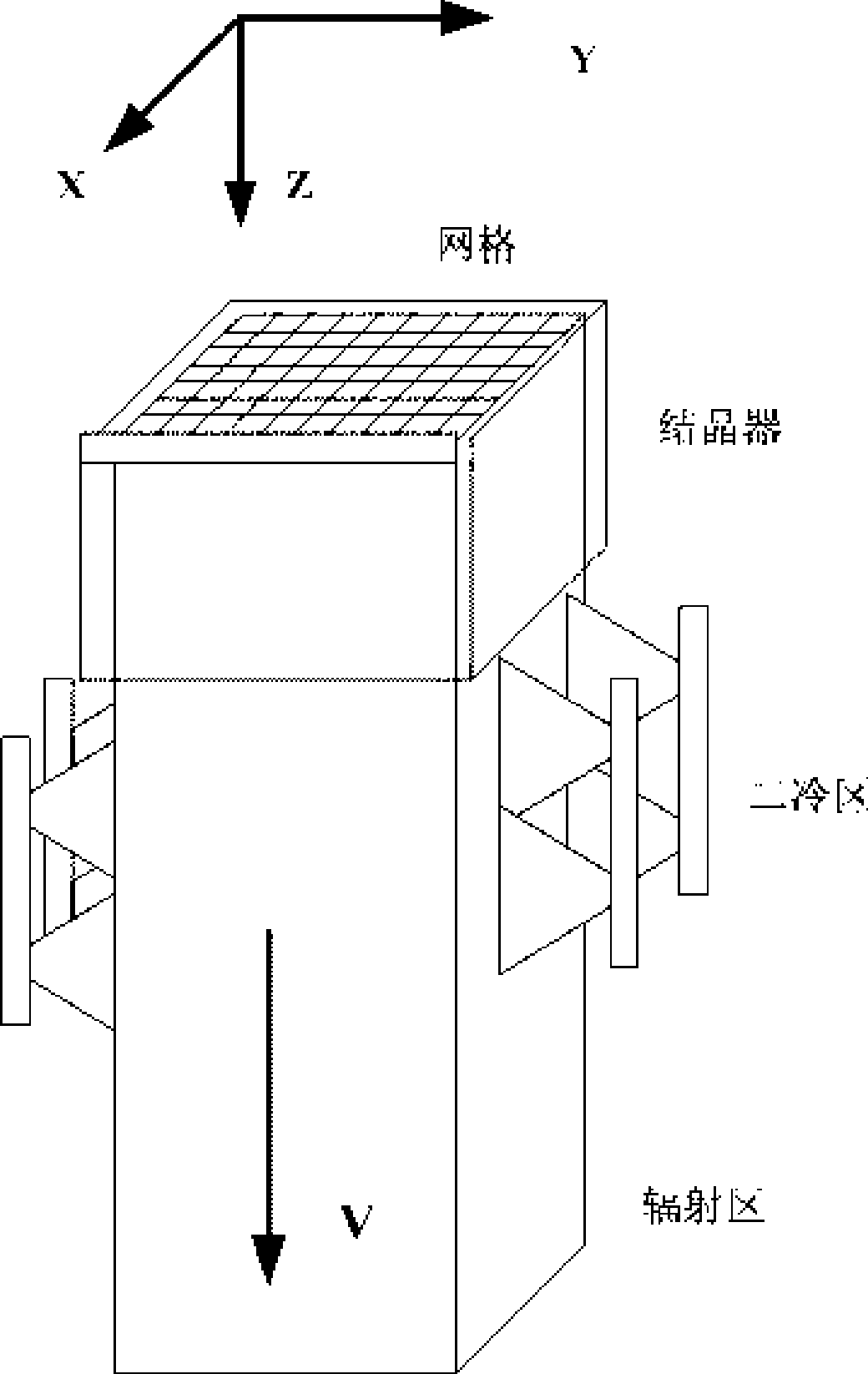

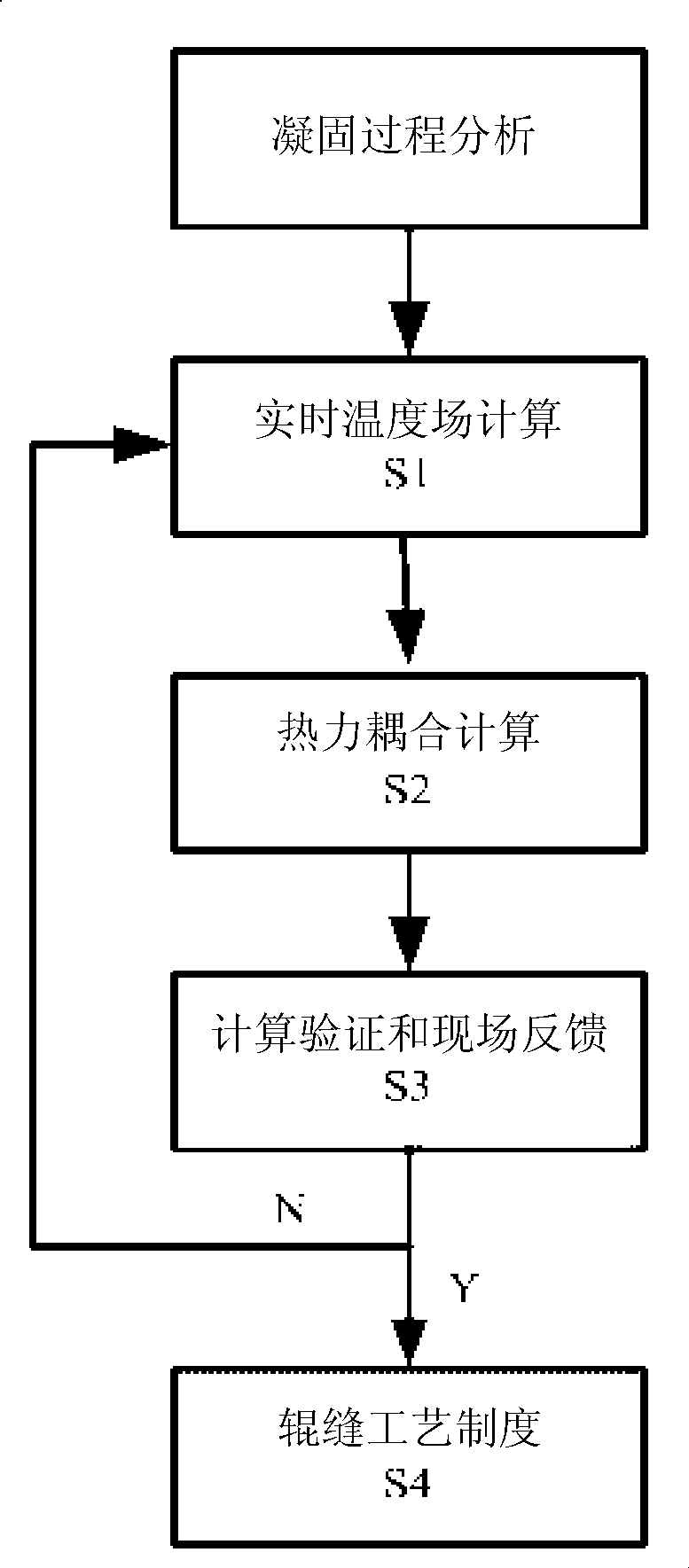

Method used

Image

Examples

Embodiment ( 1

[0048] (1) Casting machine equipment parameters: full arc-shaped bloom continuous caster, radius 15m, arc section casting roll diameter 220mm, center distance between adjacent casting rolls 210mm, straightening section and horizontal section casting roll diameter 450mm, length of pressing section It is 9200mm, and the distance between the centers of adjacent casting rolls is 1500mm.

[0049] (2) The billet size is 360mm×450mm, the steel type is YQ450NQR1, the continuous casting casting speed is 0.4-0.6m / min, the degree of superheat is 20-35°C, and the continuous casting cooling intensity is 0.321-0.375L / kg. The composition of the steel type is shown in the table 1.

[0050] Table 1

[0051] C Si mn P S 0.11~0.14 0.30~0.50 1.25~1.40 0.008~0.022 0.005~0.015

[0052] (3) The roll gap setting of each cooling zone is shown in Table 2.

[0053] Table 2

[0054]

[0055] (4) The roll gap taper and roll ...

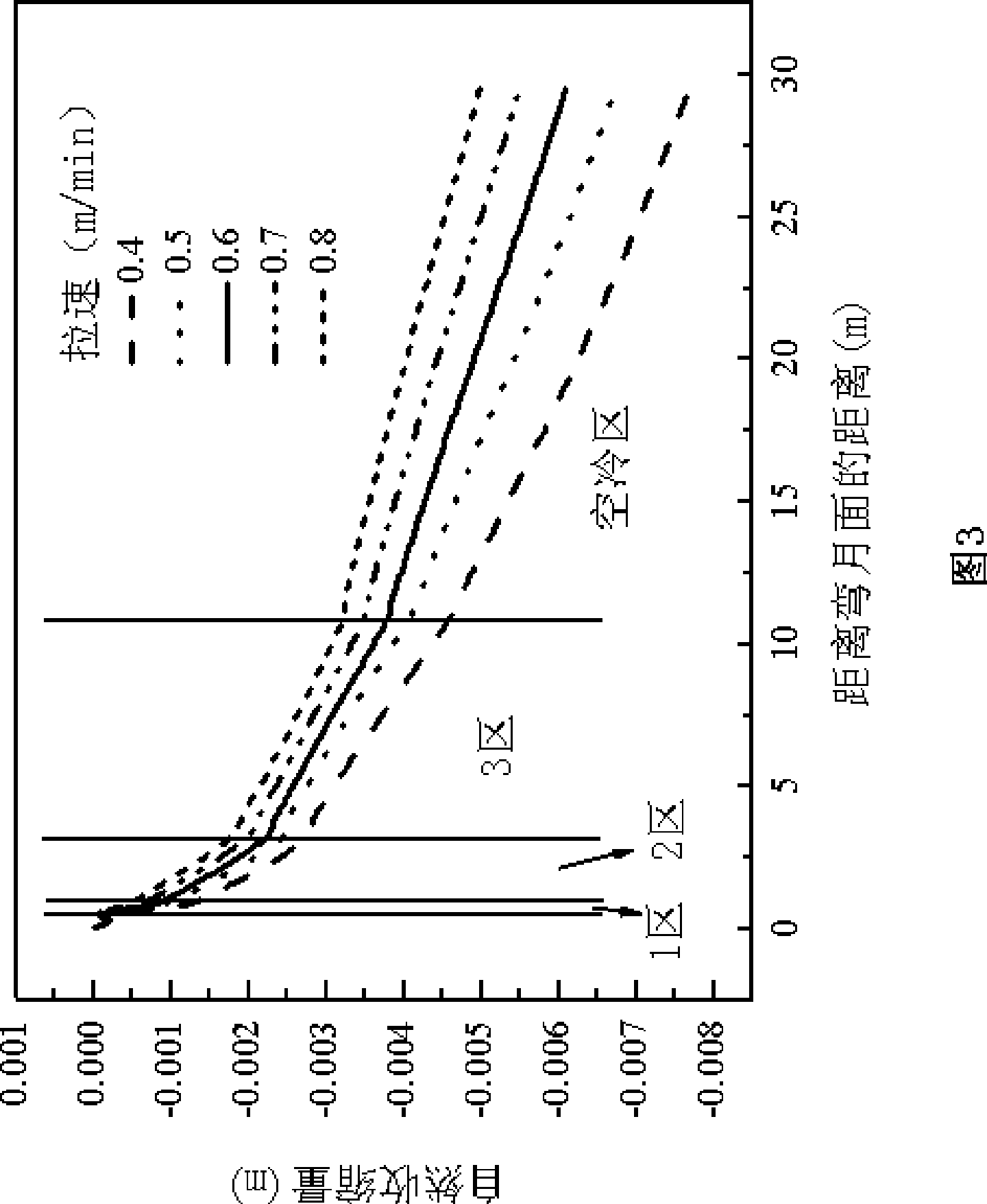

Embodiment ( 2

[0060] (1) The parameters of the casting machine equipment are as in Example (1).

[0061] (2) The billet size is 360mm×450mm, and the steel type is 45 # , the continuous casting casting speed is 0.4-0.8m / min, the degree of superheat is 20-35°C, the continuous casting cooling intensity is 0.373-0.405L / kg, and the steel composition is shown in Table 4.

[0062] Table 4

[0063] C Si mn P S 0.42~0.50 0.17~0.37 0.50~0.80 0.010~0.025 0.008~0.020

[0064] (3) The roll gap setting of each cooling zone is shown in Table 5.

[0065] table 5

[0066]

[0067] (4) The roll gap taper and roll gap reduction rate in each cooling zone are shown in Table 6.

[0068] Table 6

[0069] Each cooling zone zone 1 Zone 2 District 3 Air cooling area Taper value (%) 0.093 0.064 0.036 0.027 Roll gap reduction rate (mm / min) 1.3 0.9 0.47 0.39

[0070] (5) The dimensi...

Embodiment ( 3

[0072] (1) The parameters of the casting machine equipment are as in Example (1).

[0073] (2) The billet size is 360mm×450mm, the steel type is 20(C), the casting speed is 0.4~0.7m / min, the superheat is 20~35℃, the continuous casting cooling intensity is 0.415~0.432L / kg, the steel type The ingredients are shown in Table 7.

[0074] Table 7

[0075] C Si mn P S 0.17~0.23 0.17~0.37 0.35~0.65 0.010~0.025 0.008~0.020

[0076] (3) The roll gap setting of each cooling zone is shown in Table 8.

[0077] Table 8

[0078]

[0079] (4) The roll gap taper and roll gap reduction rate in each cooling zone are shown in Table 9.

[0080] Table 9

[0081] Each cooling zone zone 1 Zone 2 District 3 Air cooling area Taper value (%) 0.11 0.069 0.037 0.025 Roll gap reduction rate (mm / min) 0.9 0.72 0.43 0.36

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com