Preparation method for metal organic framework modified graphene oxide lamellar structure composite membrane used for organic solvent nanofiltration

A metal-organic framework and graphene sheet technology, applied in the field of membrane separation, can solve the problems of low membrane flux and poor affinity, and achieve high flux, improved separation performance, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

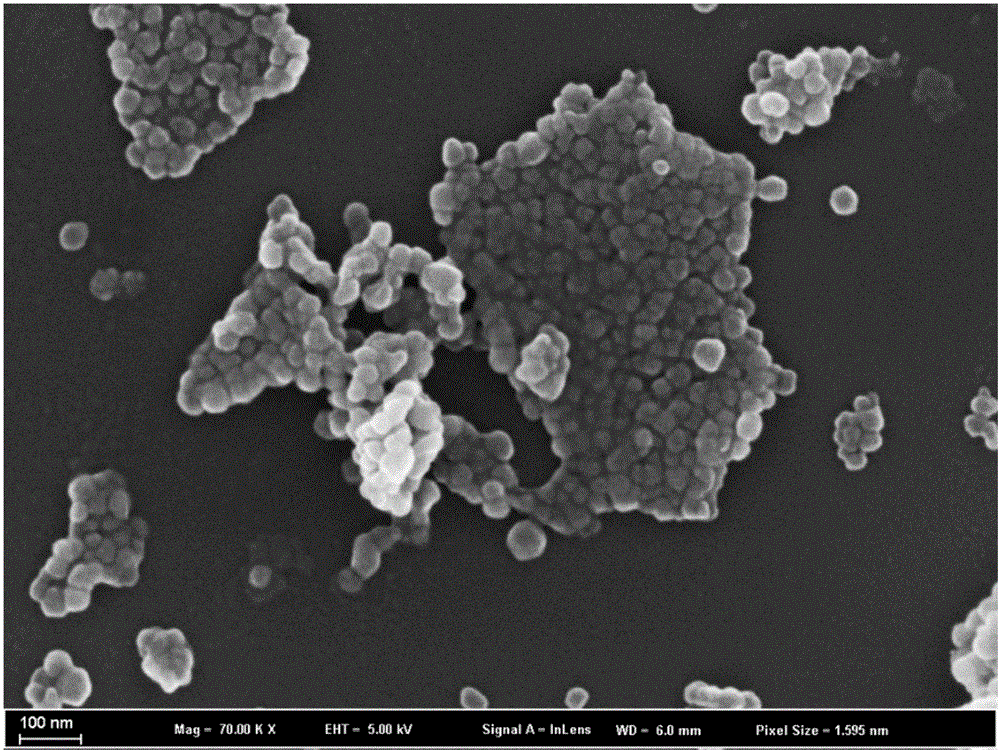

[0023] (1) Weigh 0.366g Zn(NO 3 ) 2 ·H 2 O and 0.811g 2-methylimidazole were dissolved in 12mL and 20mL of methanol, then 16mL of 1g / L GO aqueous solution was added, the three were mixed evenly, after stirring for 2h, the product was centrifuged and washed three times with methanol to obtain ZIF -8@GO composite nanoparticles.

[0024] (2) Disperse the ZIF-8@GO composite particles in methanol to form a dispersion with a mass fraction of 0.01wt%, add polyethyleneimine (PEI, 50% aqueous solution), and dissolve the concentration to 0.03wt%, both obtained Casting solution. A glutaraldehyde solution with a concentration of 0.05 wt% was then prepared as a crosslinking agent solution.

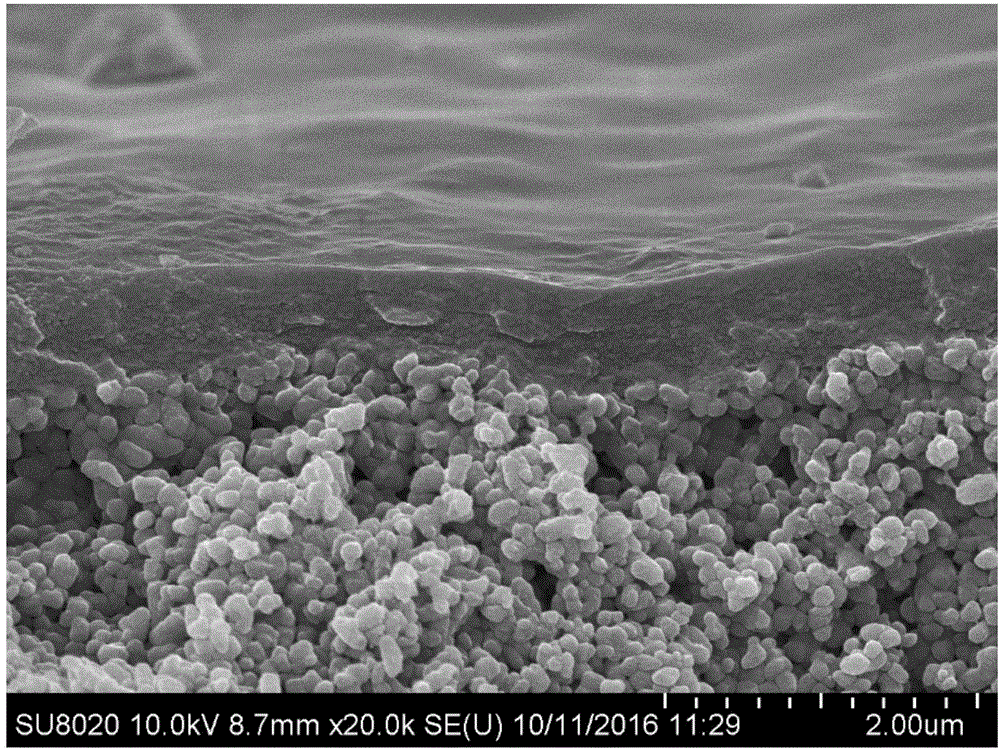

[0025] (3) The casting solution is assembled on the alumina ceramic tube base film by means of negative pressure. The specific method is to block one end of the basement membrane of the ceramic tube with a rubber plug, and connect the other end to a vacuum pump to make the inner side of the cerami...

Embodiment 2

[0029] (1) Weigh 0.366g Zn(NO 3 ) 2 ·H 2 O and 0.811g 2-methylimidazole were dissolved in 12mL and 20mL of methanol, then 16mL of 1g / L GO aqueous solution was added, the three were mixed evenly, after stirring for 1h, the product was centrifuged and washed three times with methanol to obtain ZIF -8@GO composite nanoparticles.

[0030] (2) Disperse the ZIF-8@GO composite particles in methanol to form a dispersion with a mass fraction of 0.01wt%, add polyethyleneimine (PEI, 50% aqueous solution), and dissolve the concentration to 0.03wt%, both obtained Casting solution. A glutaraldehyde solution with a concentration of 0.05 wt% was then prepared as a crosslinking agent solution.

[0031] (3) The casting solution is assembled on the alumina ceramic tube base film by means of negative pressure. The specific method is to block one end of the basement membrane of the ceramic tube with a rubber plug, and connect the other end to a vacuum pump to make the inner side of the cerami...

Embodiment 3

[0035] (1) Weigh 0.366g Zn(NO 3 ) 2 ·H 2 O and 0.811g 2-methylimidazole were dissolved in 12mL and 20mL of methanol, then 16mL of 1g / L GO aqueous solution was added, the three were mixed evenly, after stirring for 1h, the product was centrifuged and washed three times with methanol to obtain ZIF -8@GO composite nanoparticles.

[0036](2) Disperse the ZIF-8@GO composite particles in methanol to form a dispersion with a mass fraction of 0.01wt%, add polyethyleneimine (PEI, 50% aqueous solution), and dissolve the concentration to 0.04wt%, both obtained Casting solution. A glutaraldehyde solution with a concentration of 0.05 wt% was then prepared as a crosslinking agent solution.

[0037] (3) The casting solution is assembled on the alumina ceramic tube base film by means of negative pressure. The specific method is to block one end of the basement membrane of the ceramic tube with a rubber plug, and connect the other end to a vacuum pump to make the inner side of the ceramic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com