Hydrophobic/hydrophilic composite membrane with nuclear track etching membrane as base membrane as well as preparation method and application of same

A nuclear track etching, composite membrane technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of limiting the application of hydrophobic/hydrophilic composite membranes, cumbersome preparation, etc., and achieve excellent physical and mechanical properties. The effect of low rate and random dispersion of pore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 prepared a hydrophobic / hydrophilic composite membrane sample 1, the specific preparation process is as follows:

[0050] (1) The mass fraction of polyvinylidene fluoride is 15%, the solvent DMAc79%, and the additives are: Licl3% and acetone 3%;

[0051] (2) Add the mixed raw materials weighed in step (1) into the reactor, and stir electrically for about 12 hours in a constant temperature water bath at 60°C to form a uniform and stable casting solution, which is left to stand at room temperature for defoaming for 12 hours to obtain a homogeneous casting solution. Membrane fluid;

[0052] (3) Scrape the liquid film of 100 μm on the glass plate that (2) gained film-casting liquid is glued with PET nuclear track film with scraper, immerse earlier 5 minutes in 20% ethanol solution, treat that its phase separation completes taking out and use Rinse with deionized water;

[0053] (4) Transfer the film prepared in step (3) into deionized water and soak for 24 hours,...

Embodiment 2

[0058] Embodiment 2 has prepared hydrophobic / hydrophilic composite membrane sample 2, and concrete preparation process is basically consistent with embodiment 1, and difference only is that the mass fraction of polyvinylidene fluoride, additive Licl, acetone is different in the raw material, mass fraction refers to step ( 1) The mass fraction of each substance in the raw material. The specific preparation conditions are shown in Table 1 below.

[0059] Table 1 Preparation conditions of hydrophobic / hydrophilic composite membrane samples 1 and 2

[0060]

[0061] Wherein the performance test method of hydrophobic / hydrophilic composite membrane sample 2 is also completely consistent with embodiment 1, and the results are as follows:

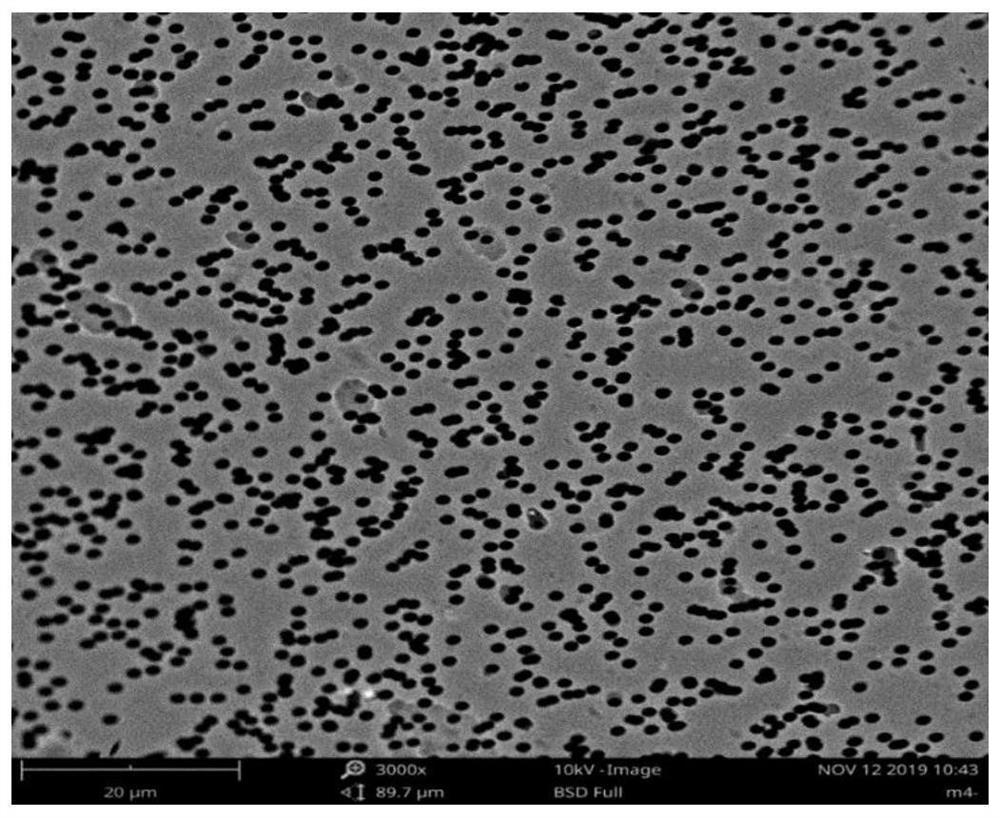

[0062] The membrane section of the hydrophobic / hydrophilic composite membrane sample 2 has a sponge-like pore structure ( Figure 6 ), the porosity is 37.63%, the average pore diameter is 0.1242μm, and the gas permeability is 0.956L cm -2 cm ...

Embodiment 3-4

[0066] In Example 3-4, the hydrophobic / hydrophilic composite membrane sample 3-4 was prepared, and the specific preparation process was basically the same as that in Example 1, except that the content of additives in the raw materials was slightly different. The specific preparation conditions are shown in Table 2 below.

[0067] Table 2 Preparation conditions of hydrophobic / hydrophilic composite membrane samples 3 and 4

[0068]

[0069]

[0070] Wherein the performance test method of hydrophobic / hydrophilic composite membrane sample 3-4 is also completely consistent with embodiment 1, and the results are as follows:

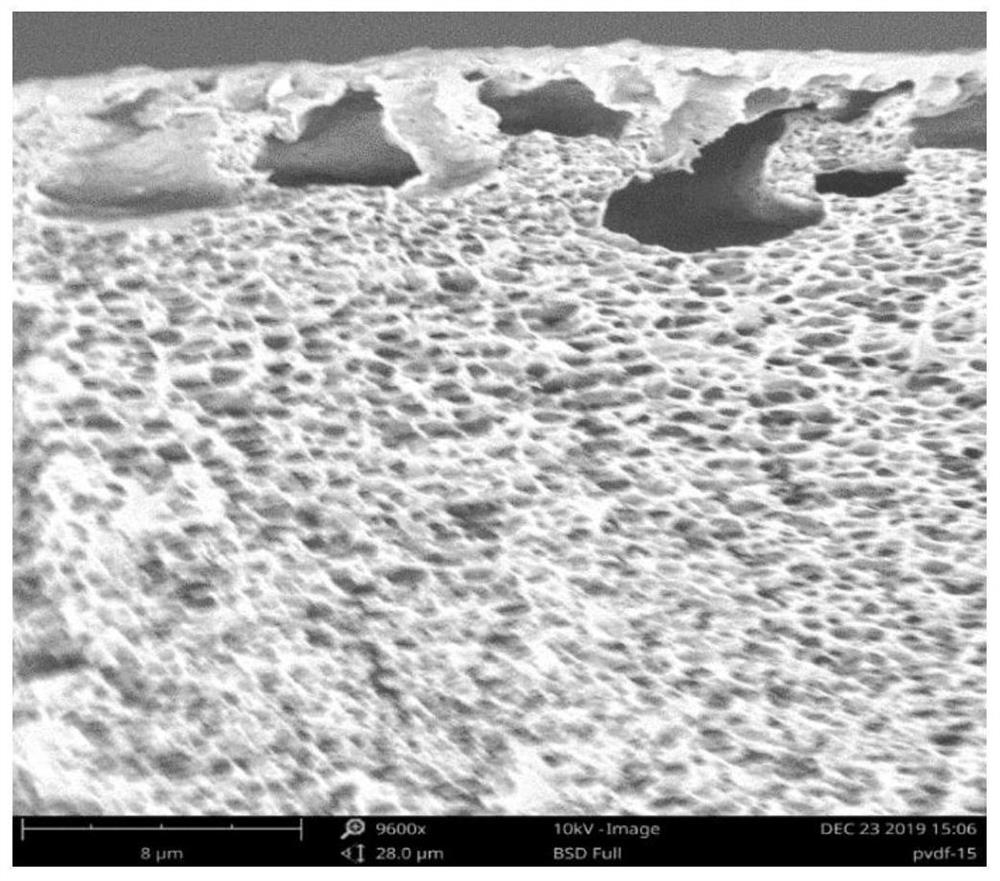

[0071] The membrane section of the hydrophobic / hydrophilic composite membrane sample 3 has a finger-like pore structure with a large number, and the lower part is a sponge pore structure ( Figure 8 ), the porosity is 37.63%, the average pore diameter is 0.112μm, and the gas permeability is 0.812L·cm -2 cm -1 , The water contact angle is 90.2°, the water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com