A clinically applicable barium titanate modified zirconia ceramic material

A technology of zirconia ceramics and barium titanate, applied in the field of barium titanate modified zirconia ceramic materials and their preparation, can solve problems such as poor osseointegration effect, and achieve increased porosity, good biocompatibility, and good The effect of osteogenic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

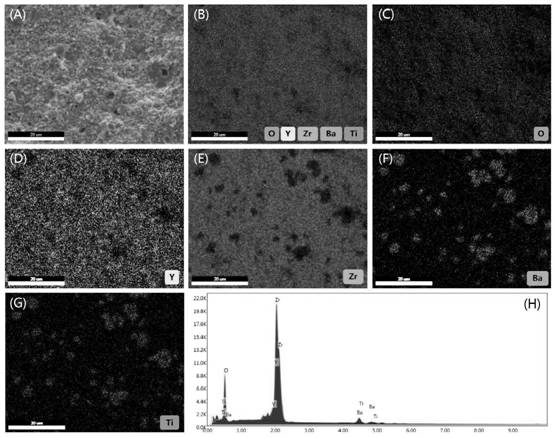

[0047] The raw material powder used in this example is 5mol% barium titanate (BT) powder, commercialized 3mol% yttria-stabilized tetragonal zirconia polycrystalline ceramic powder (3Y-TZP), wherein the particle size of barium titanate is 1μm, 3mol% The particle size of the yttria-stabilized tetragonal zirconia polycrystalline ceramic powder is 300-500 nm.

[0048] The preparation method steps of this embodiment are as follows:

[0049] (1) Preparation of ceramic slurry: mix barium titanate with 3 mol% of commercial yttria-stabilized tetragonal zirconia polycrystalline ceramic powder (3Y-TZP) according to 5 mol% molar percentage to obtain a mixed powder, add the mixed powder to the In a water-ethanol (analytical grade) solution, a mixture is obtained so that the volume of the raw material powder accounts for 35% of the total volume of water and powder, and the mixture is ball milled and mixed for 10 hours to obtain a ceramic slurry.

[0050] (2) Biscuit firing and sieving: put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com