Preparation method of graphene oxide separation membrane with adsorption function, and product prepared therethrough

A graphene and separation membrane technology, applied in the field of graphene oxide separation membrane preparation, can solve the problems of unstable adsorption performance, difficult recovery, secondary pollution, etc., and achieve the effect of excellent product performance, low cost and high separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

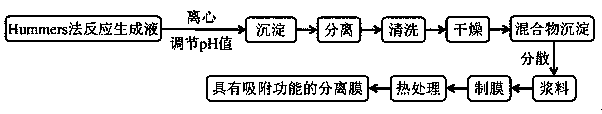

[0025] Adopt Hummers method to prepare graphene oxide, under the centrifugation speed of 5000 rpm, centrifuge the reaction product solution for 20 minutes, measure the reaction product solution 200 milliliters, drop ammonia solution thereinto until precipitation is formed, then mix The pH value of the solution is 8. After the above precipitate was filtered, separated, cleaned and dried, a mixed precipitate of nanometer hydrated manganese oxide and graphene oxide was obtained; an appropriate amount of the above mixture precipitate was weighed and ultrasonically dispersed into water to obtain a film-making slurry with a solid content of 5 wt%. The membrane-making slurry, combined with the spin coating method, prepares a graphene oxide separation membrane containing nanometer hydrated manganese oxide on an alumina porous ceramic support with an average pore diameter of 150 nanometers; the membrane is treated at 100 ° C for 2 hours, that is Corresponding film products with a thick...

Embodiment 2

[0028] Adopt Hummers method to prepare graphene oxide, under the centrifugation speed of 8000 rpm, centrifuge the reaction product solution for 10 minutes, measure 200 milliliters of the reaction product solution, drop ammonia solution thereinto until the precipitation is formed, then mix The pH value of the liquid is 7; after the above precipitate is filtered, separated, washed and dried, a mixed precipitate of nano-manganese hydrated manganese oxide and graphene oxide is obtained; an appropriate amount of the above-mentioned precipitate of the mixture is ultrasonically dispersed in water to obtain a solid content of 2 wt%. Membrane-making slurry; using the membrane-making slurry, combined with a spin-coating method, on a zirconia porous ceramic support with an average pore diameter of 100 nanometers, a graphene oxide separation membrane containing nanometer hydrated manganese oxide is prepared; the membrane is heated at 150°C The corresponding membrane product with a thicknes...

Embodiment 3

[0031] Adopt Hummers method to prepare graphene oxide, under the centrifugal speed of 6000 r / min, centrifuge the reaction product solution for 15 minutes, measure 200 milliliters of the reaction product solution, drop ammonia solution thereinto until the precipitation is formed, then mix The pH value of the solution is 6. After the above precipitate was filtered, separated, cleaned and dried, a mixed precipitate of nanometer hydrated manganese oxide and graphene oxide was obtained; an appropriate amount of the above precipitate was weighed and ultrasonically dispersed into water to obtain a film-making slurry with a solid content of 3 wt%. The membrane-making slurry, combined with the spin coating method, is prepared on a polytetrafluoroethylene membrane support with an average pore size of 200 nanometers, and a graphene oxide separation membrane containing nano-hydrated manganese oxide is prepared; the membrane is treated at 100 ° C for 2 hours , the corresponding membrane pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com