Method for preparing hydrophobic graphene film

A technology of graphene film and graphene dispersion, which is applied in the fields of graphene, general water supply saving, chemical instruments and methods, etc., can solve the problems that limit the practical application of graphene oxide, and achieve the effect of simple preparation process and high separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

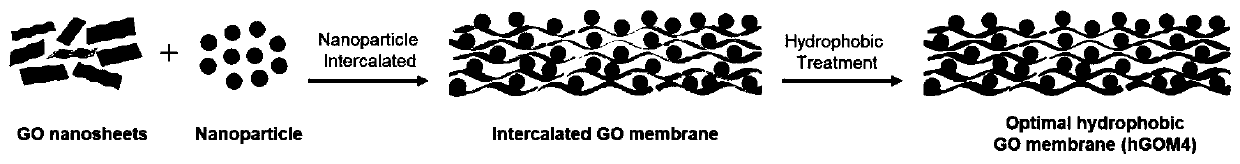

[0026] The method of the present invention is used to prepare hexadecyltrimethoxysilane modified hydrophobic graphene film (the preparation process is as follows: figure 1 Shown).

[0027] (1) Preparation of graphene dispersion: add 0.25 mg of graphene oxide to 200 mL of water, stir and sonicate to obtain a uniformly dispersed graphene aqueous solution;

[0028] (2) Preparation of nano-particle dispersion: add 0.02 g of silica with a particle size of 200 nm to 20 mL of water, and after ultrasonic and stirring, a uniform silica dispersion is obtained;

[0029] (3) Preparation of hydrophobic modifier: 4g cetyltrimethoxysilane, 2g water and 198g ethanol are uniformly mixed, and after stirring, a hydrolyzed hydrophobic modifier solution is obtained;

[0030] (4) Preparation of rough graphene film: add 0.25 mL of silica dispersion to the above graphene dispersion, stir for 2 hours, and use vacuum filtration to form a film on the polyacrylonitrile support (film thickness ~ 350nm) , After dr...

Embodiment 2

[0034] The method of the present invention is used to prepare a hydrophobic graphene film modified by dodecyltrimethoxysilane (the preparation process is as follows: figure 1 Shown).

[0035] (1) Preparation of graphene dispersion: 0.22 mg of graphene oxide was added to 100 mL of water, stirred and sonicated to obtain a uniformly dispersed graphene aqueous solution;

[0036] (2) Preparation of nano-particle dispersion: 0.01 g of silica with a particle size of 250 nm is added to 10 mL of water, and after ultrasound and stirring, a uniform silica dispersion is obtained;

[0037] (3) Preparation of hydrophobic modifier: 3.8g of dodecyltrimethoxysilane, 2.2g of water and 198g of ethanol are uniformly mixed, and after stirring, a hydrolyzed hydrophobic modifier solution is obtained;

[0038] (4) Preparation of rough graphene film: 0.22 mL of silica dispersion was added to the above graphene dispersion, stirred for 2 hours, and vacuum filtration was used to form a film on the polyacrylonitri...

Embodiment 3

[0042] The method of the present invention is used to prepare octadecyltrimethoxysilane modified hydrophobic graphene film (the preparation process is as figure 1 ).

[0043] (1) Preparation of graphene dispersion: add 0.4 mg of graphene oxide to 100 mL of water, stir and ultrasonic to obtain a uniformly dispersed graphene aqueous solution;

[0044] (2) Preparation of nanoparticle dispersion: add 0.03 g of silica with a particle size of 280 nm to 30 mL of water, and after ultrasonic and stirring, a silica dispersion is obtained;

[0045] (3) Preparation of hydrophobic modifier: Mix 5g of octadecyltrimethoxysilane, 2g of water and 197g of ethanol uniformly, and after stirring, obtain a hydrolyzed hydrophobic modifier solution;

[0046] (4) Preparation of rough graphene film: 0.4mL of silica dispersion was added to the above graphene dispersion, stirred for 2h, and a film was formed on the polycarbonate support by vacuum filtration (film thickness ~500nm) , After drying at 40℃ for 12h, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com