Unpowered anti-blocking grate bar slide sieve

A grate and power technology, which is applied in the field of material screening equipment, can solve the problems of insufficient material screening and analysis, non-compliance, difficult installation and maintenance, etc., and achieve the effect of simple and uniform material distribution, accelerated flow speed, and easy centralized collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

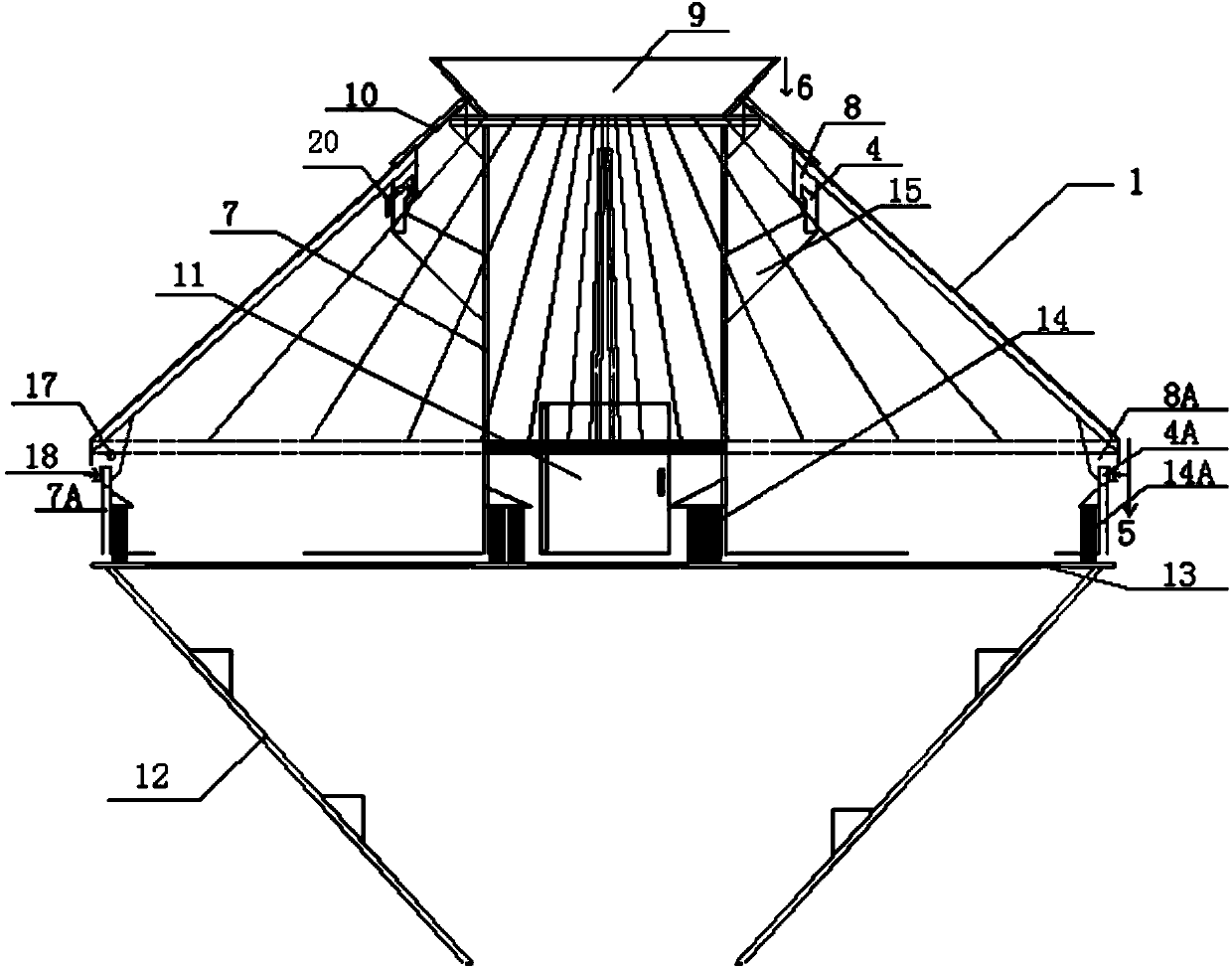

[0034] The sieve plate is a single-layer conical non-powered anti-jamming grate sieve:

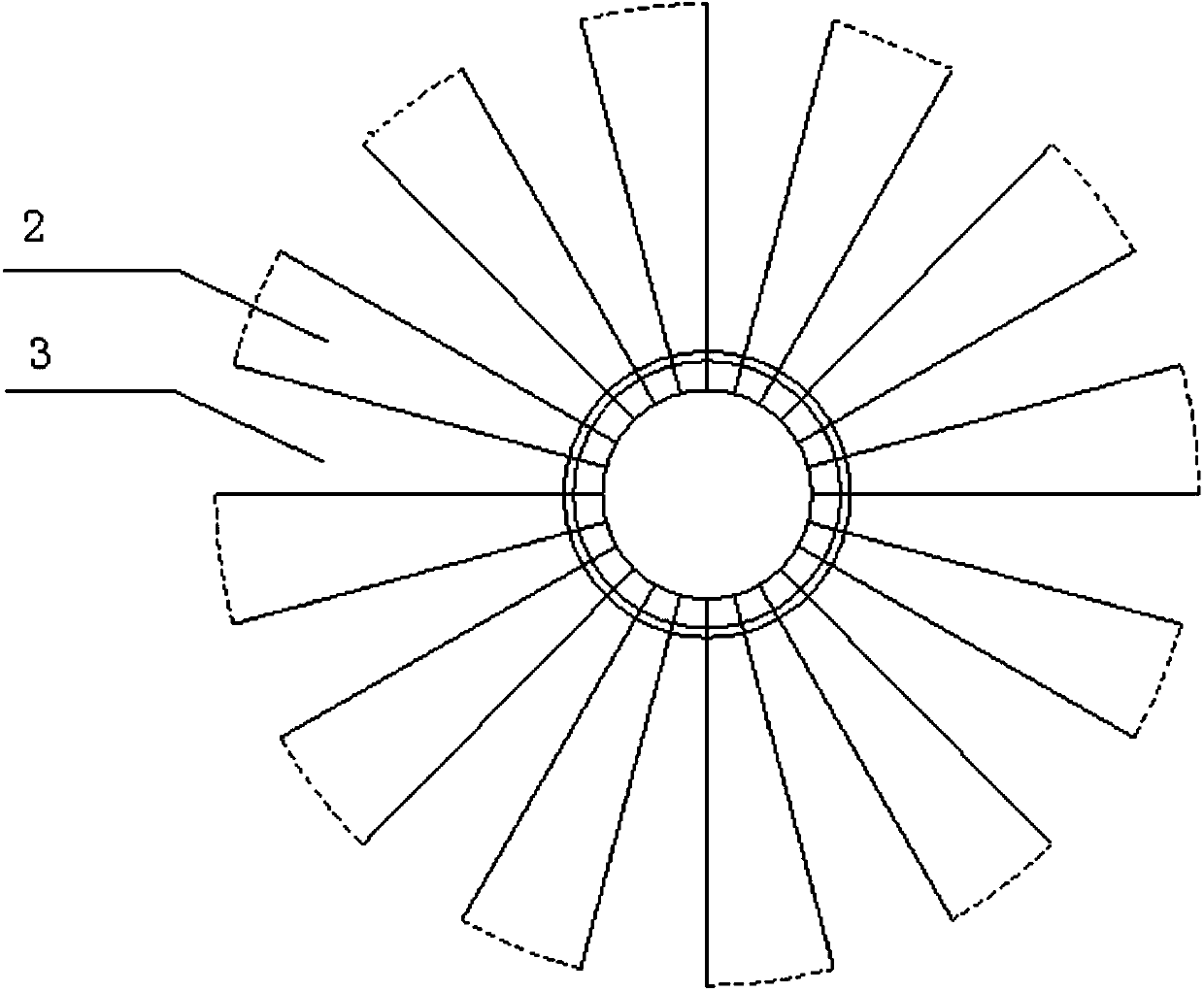

[0035] A non-powered anti-seize grate sieve, comprising a sieve plate (1), on the sieve plate (1) there are a plurality of gaps (3) open at one end along the sliding direction of materials, between adjacent gaps (3) There is a grate (2) between them, and it is characterized in that: the gap (3) and the grate (2) are distributed at intervals, one end of the sieve plate (1) is located below the feed port (6), and the other end is the discharge port (5), under the sieve plate (1) close to the feed inlet (6), install it on the upper beam (4) inside the screen body through the grate upper support frame (8), and the upper beam (4) is fixed on the sieve plate On the upper beam supporting frame (15), the sieve upper beam supporting frame (15) is fixed on the inner sieve body (7); the bottom of the sieve plate (1) is installed near the outlet ( 5) On one end of the lower beam (4A), the lower beam ...

Embodiment 2

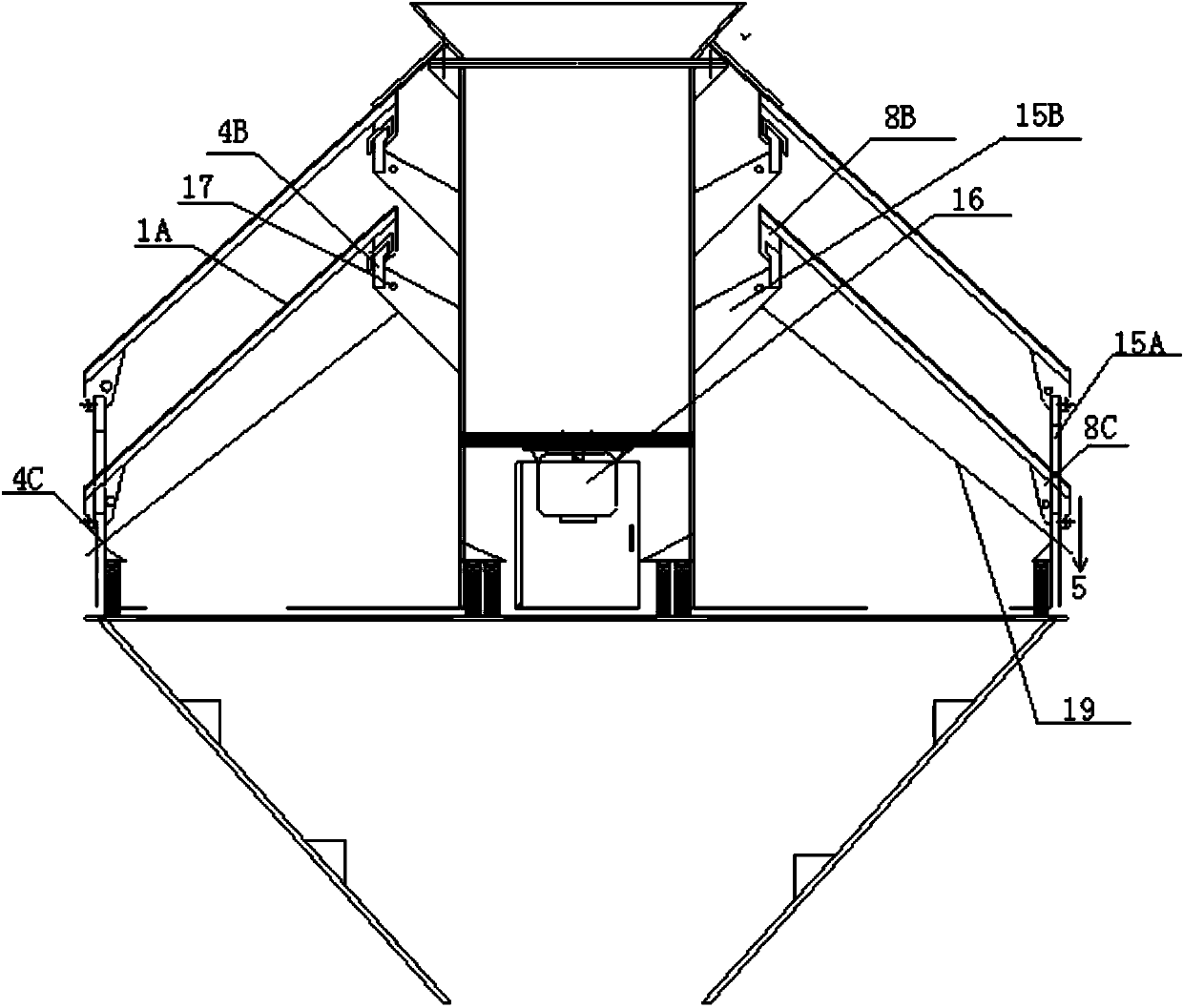

[0047] The sieve plate is a double-layer conical non-powered anti-jamming grate sieve

[0048] The bottom sieve plate (1A) is set under the sieve plate (1) in Example 1, the lower beam (4A) of the sieve plate (1) is fixed on the sieve plate lower beam support (15A), and the sieve plate lower beam support (15A ) and the lower beam (4C) of the bottom sieve plate are fixed on the outer sieve body (7A); the screen mesh (19) can be laid on the upper surface of the bottom sieve plate (1A) or hoisted on the grate The lower support frame (8A) or the upper support frame (8B) of the bottom sieve plate grate bar, the bottom sieve plate grate bar lower support frame (8C) is provided with on the paving and hanging screen mesh hole, and others are all the same as in embodiment 1.

[0049] The screening process of embodiment 2

[0050] Its upper sieving process is all the same as in Example 1, and the lower sieve plate (1A) is subjected to the fine material material supplied by the material...

Embodiment 3

[0053] A non-powered anti-jamming grate sieve with a flat sieve plate, such as Figure 7 Shown:

[0054] An unpowered anti-jamming grate sieve, comprising a rectangular sieve plate (21), on which there are a plurality of rectangular sieve gaps (29) with one end open along the material sliding direction, and adjacent rectangular sieve gaps (29). A rectangular sieve grate (30) is arranged between the sieve gaps (29), and it is characterized in that: the rectangular sieve plate (21) is a plane, and the sieve plate is installed on the rectangular sieve plate beam inside the rectangular sieve body (24) (23) or on an external fixable object, the rectangular sieve plate (21) is arranged obliquely with the horizontal plane along the material sliding direction, the rectangular sieve plate beam (23) is installed on the rectangular sieve body (24), and the rectangular sieve plate One end of (21) is located below the rectangular sieve inlet (26), and the other end is the rectangular siev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com