Bead-like nanofiber fuel filter membrane and preparation method thereof

A nanofiber membrane and nanofiber technology, which is applied in the field of fiber materials, can solve the problems of long process flow, limited material filtration accuracy, and inability to obtain nano-sized beads with a particle size, so as to increase the roughness and improve the separation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

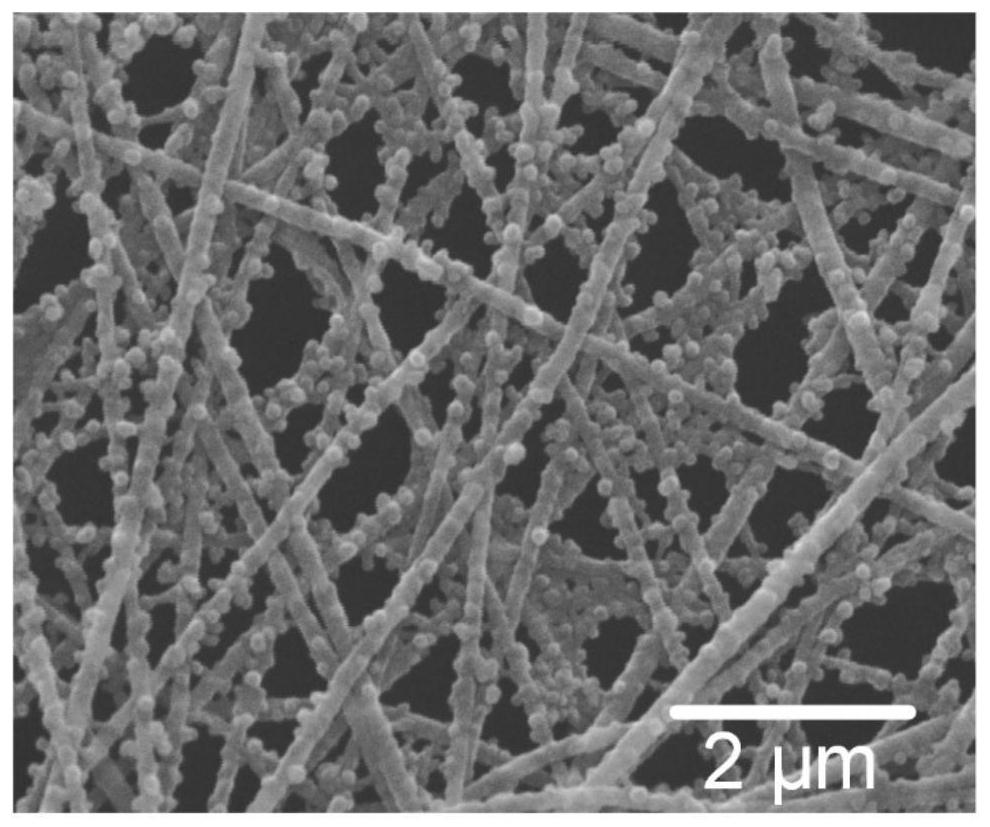

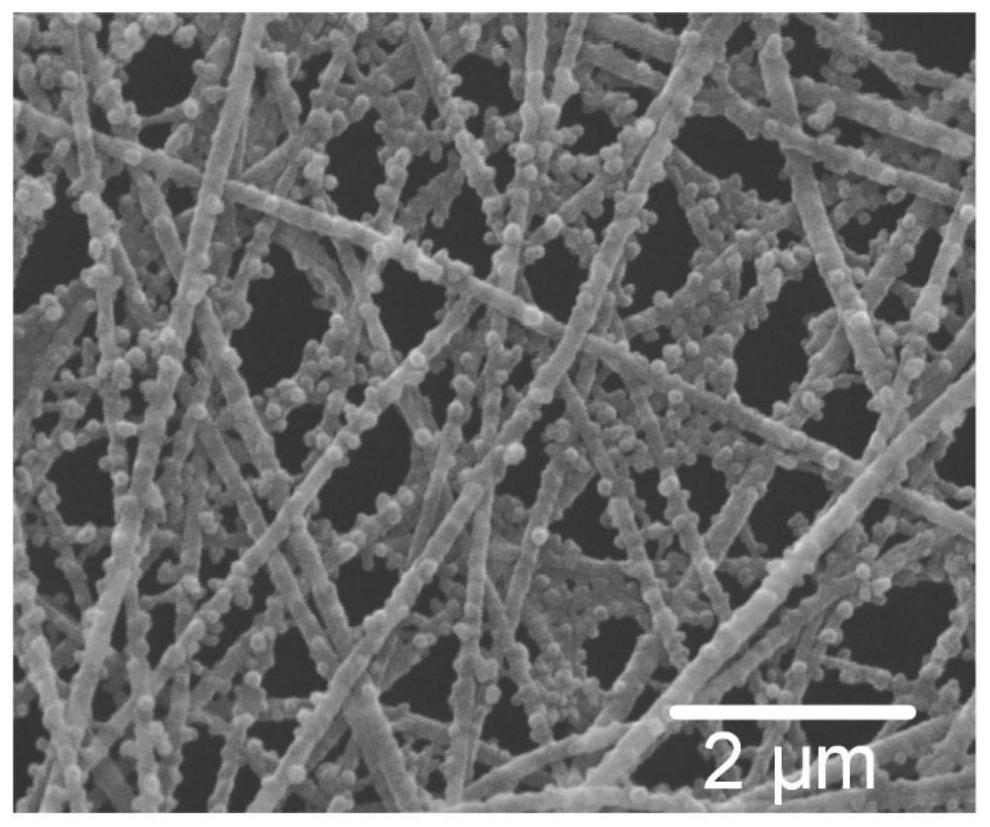

[0028] A method for preparing a beaded nanofiber fuel filter membrane, firstly selecting a weight-average molecular weight of 5 × 10 4 The polymer (polyacrylonitrile) of g / mol and solvent (dimethyl sulfoxide) configure polymer solution, add the non-solvent (methanol) of 0.001wt% to the solution and obtain concentration is 1wt%, viscosity is 200mPa.s Microgel mixed solution. Then the selected polyamide electrospun nanofiber substrate was impregnated to a volume of 5ul cm -2 Immersed in the mixed solution of , and after taking it out, put it in an ultrasonic-assisted non-solvent (methanol) coagulation bath with a frequency of 20kHz and a power of 50W for phase separation to prepare a beaded nanofiber membrane, followed by polydimethyl Siloxane is a hydrophobic finishing agent, and the beaded nanofiber membrane is hydrophobically treated by the impregnation method to prepare a beaded nanofiber membrane for fuel filtration, such as figure 1 shown.

[0029] The average particle ...

Embodiment 2

[0031] A method for preparing a beaded nanofiber fuel filter membrane. Firstly, a weight-average molecular weight of 57×10 4 g / mol polymer (polyvinylidene fluoride) and solvent (N,N-dimethylformamide) configure the polymer solution, add 0.01wt% non-solvent (water) to the solution to obtain a concentration of 2wt%, viscosity It is a microgel mixed solution at 800mPa.s. Then, the selected polytetrafluoroethylene electrospun nanofiber substrate was impregnated with an amount of 10ul cm -2 Immersed in the mixed solution of , and after taking it out, put it in an ultrasonically assisted non-solvent (a mixture of water and N,N-dimethylformamide) coagulation bath with a frequency of 20kHz and a power of 100W for phase separation, where N, The amount of N-dimethylformamide accounts for 2wt% of the specific gravity of the coagulation bath, and a beaded nanofiber membrane is prepared, and then polymethylhydrogensiloxane is used as a hydrophobic finishing agent, and the beaded structure...

Embodiment 3

[0034] A method for preparing a beaded nanofiber fuel filter membrane, firstly selecting a weight-average molecular weight of 20×10 4 g / mol polymer (polysulfone) and solvent (N,N-dimethylformamide) configure polymer solution, add 0.15wt% non-solvent (ethanol) to the solution to obtain a concentration of 3wt% and a viscosity of 800mPa .s microgel mixed solution. Then the selected polyethylene terephthalate electrospun nanofiber substrates were impregnated to a volume of 15ul cm -2 Immersed in the mixed solution of , after taking it out, put it in an ultrasonically assisted non-solvent (ethanol) coagulation bath with a frequency of 30kHz and a power of 120W for phase separation to prepare a beaded nanofiber membrane, and then use water-based polyurethane as a hydrophobic The finishing agent is to carry out hydrophobic treatment on the nanofiber membrane with beaded structure by spraying method, so as to prepare the beaded nanofiber membrane for fuel filtration.

[0035] The av...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Hydrophobic angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com