Sludge treatment system and method

A sludge treatment and sludge technology, applied in the direction of sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the problem of low organic matter content, affecting the gas production rate of anaerobic fermentation, carbon dioxide in the anaerobic stage, etc. Insufficient source and other problems, to improve the separation performance and reduce the amount of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

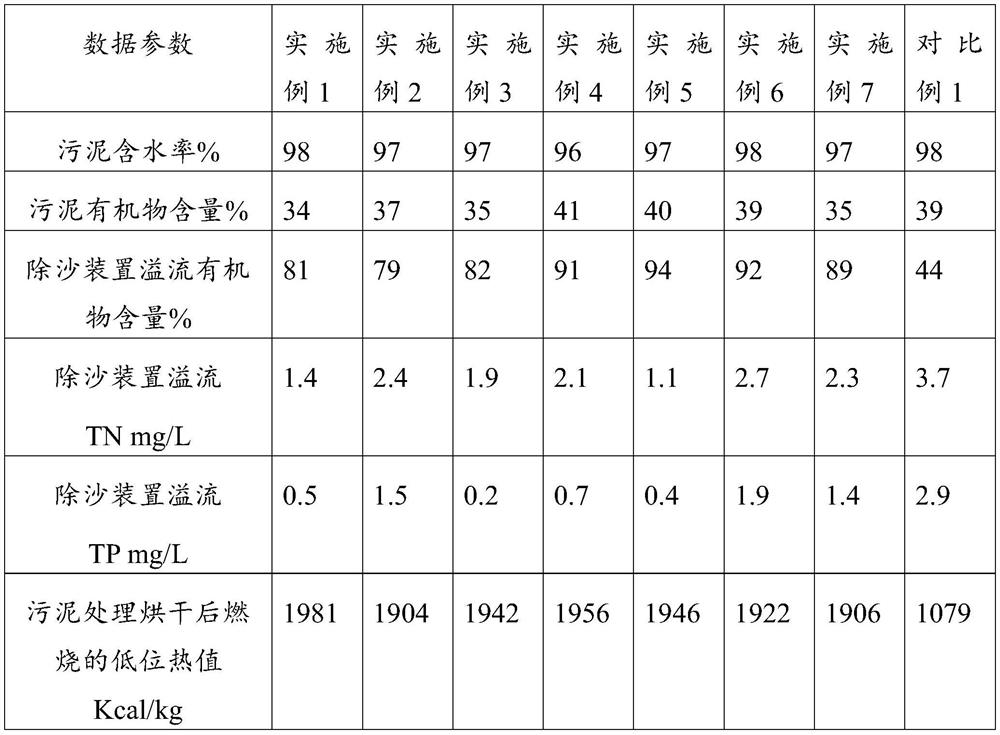

Embodiment 1

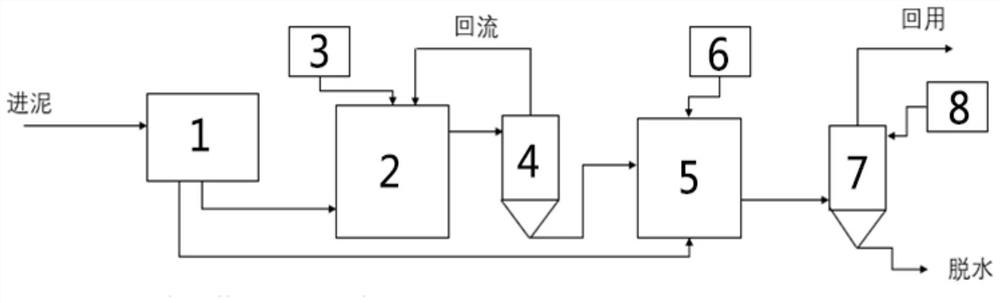

[0068] This embodiment provides a sludge treatment system, such as figure 1 shown, including:

[0069] Sludge screening device 1 is connected to the secondary sedimentation tank of the sewage plant, and is used to screen large particles of sludge, plastics and other flocs;

[0070] The sludge conditioning device 2 is equipped with a dosing and stirring device 3 which is connected to the sludge screening device for sludge conditioning;

[0071] The sludge thickening device 4 is connected with the sludge outlet of the sludge conditioning device for sludge thickening;

[0072] The acidification device 5 is equipped with a stirring device 6 and is connected to the sludge screening device and the sludge thickening device for acidification of the sludge;

[0073] The sediment separation device 7 is equipped with a magnesium salt dosing device 8, which is connected to the acidification device for the separation of sludge and sand.

[0074] Preferably, the sludge screening device i...

Embodiment 2

[0080] This embodiment provides a sludge treatment system, such as figure 1 shown, including:

[0081] Sludge screening device 1 is connected to the secondary sedimentation tank of the sewage plant, and is used to screen large particles of sludge, plastics and other flocs;

[0082] The sludge conditioning device 2 is equipped with a dosing and stirring device 3 which is connected to the sludge screening device for sludge conditioning;

[0083] The sludge thickening device 4 is connected with the sludge outlet of the sludge conditioning device for sludge thickening;

[0084] The acidification device 5 is equipped with a stirring device 6 and is connected to the sludge screening device and the sludge thickening device for acidification of the sludge;

[0085] The sediment separation device 7 is equipped with a magnesium salt dosing device 8, which is connected to the acidification device for the separation of sludge and sand.

[0086] Preferably, the sludge screening device i...

Embodiment 3

[0092] This embodiment provides a sludge treatment system, such as figure 1 shown, including:

[0093] The sludge screening device 1 is connected to the secondary sedimentation tank of the sewage treatment plant, and is used to screen large particles of sand, plastics and other flocs in the sludge;

[0094] The sludge conditioning device 2 is equipped with a dosing and stirring device 3 which is connected to the sludge screening device for sludge conditioning;

[0095] The sludge thickening device 4 is connected with the sludge outlet of the sludge conditioning device for sludge thickening;

[0096] The acidification device 5 is equipped with a stirring device 6 and is connected to the sludge screening device and the sludge thickening device for acidification of the sludge;

[0097] The sediment separation device 7 is equipped with a magnesium salt dosing device 8, which is connected to the acidification device for the separation of sludge and sand.

[0098] Preferably, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Lower calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com