Polyarylester composite nanofiltration membrane and preparation method thereof

A technology of composite nanofiltration membrane and polyarylate, which is applied in the field of composite membranes, can solve the problems of inability to use strong polar solvents and low flux of solvent-resistant nanofiltration membranes, so as to improve membrane permeation flux, non-polluting human body, Effect of Solvent Resistance and Separation Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

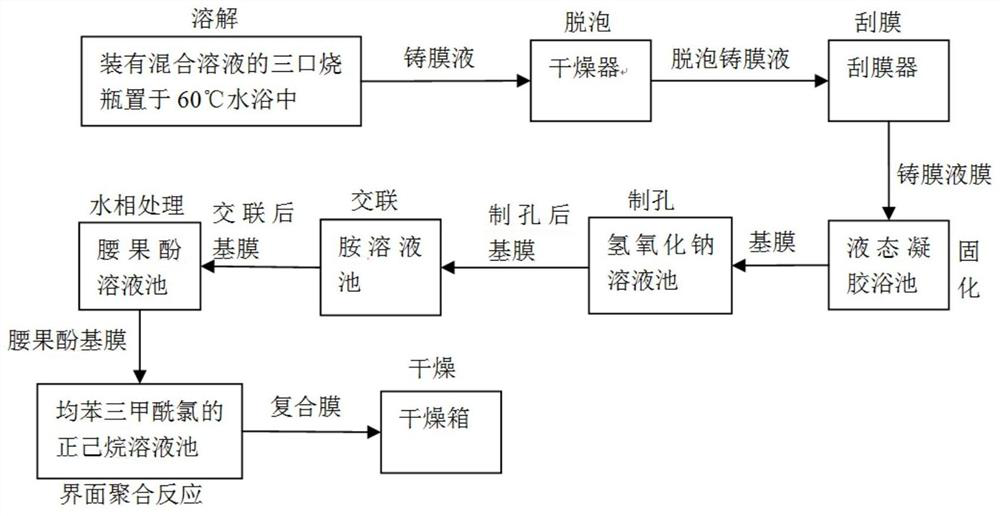

[0036] figure 1 For the preparation process of the polyarylate composite nanofiltration membrane of the present invention, see figure 1 , specifically as follows: the first step, prepare polyimide casting solution: mix polyimide particles, silicon dioxide powder and organic solvent, and prepare polyimide with a mass concentration of 15% to 30%, two The mass concentration of silicon oxide is a mixed solution of 0.1% to 10%. Stir the mixed solution at 60°C for 4 to 10 hours. After standing and cooling, put it in a desiccator for degassing for 24 hours to make a polyimide casting film. Liquid; second step, prepare base film: polyimide film casting solution is poured on the non-woven fabric, utilizes scraper such as stainless steel scraper to evenly coat polyimide casting film solution on the non-woven fabric, the The non-woven fabric is fixed on the glass plate, and the distance between the knife edge of the stainless steel scraper and the non-woven fabric is controlled to be 15...

Embodiment 1

[0048] In order to solve the above-mentioned technical problems existing in the prior art, an embodiment of the present invention provides a method for preparing a polyarylate composite nanofiltration membrane.

[0049] The preparation process of the polyarylate composite nanofiltration membrane of this embodiment is carried out in a constant temperature box at 25 ° C. In this embodiment, cardanol is used as the aqueous phase monomer, and other conditions are the same as those of the comparative example, such as figure 1 As shown, the preparation method of the polyarylate composite nanofiltration membrane of the present embodiment specifically comprises the following steps:

[0050] One, the mass concentration of preparation polyimide P84 is 15%, and the mass concentration of silicon dioxide is 0.1% N,N-dimethylacetamide (DMAc) solution, stirs 4 hours in 60 ℃ of water baths, static After cooling, put it into a desiccator for degassing for 24 hours to obtain a casting solution....

Embodiment 2

[0059] The preparation process of the polyarylate composite nanofiltration membrane of the present embodiment is carried out in a constant temperature box at 25°C, as follows:

[0060] One, the mass concentration of preparation polyimide P84 is 15%, and the mass concentration of silicon dioxide is 1% N,N-dimethylacetamide (DMAc) solution, stirs 4 hours in 60 ℃ of water baths, static After cooling, put it into a desiccator for degassing for 8 hours to obtain a casting solution. The defoamed casting solution was evenly scraped on the non-woven fabric fixed on the glass plate with a stainless steel scraper, and the distance between the knife edge and the non-woven fabric was controlled to be 150 μm. Immediately put the scraped cast film liquid film into a gel bath of water at 25°C, take it out for refrigeration after 1 hour, put it into 0.1mol / L sodium hydroxide solution for treatment for 6 hours after cleaning, and refrigerate to obtain the base For the film, the side of the no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com