Cement material fly-ash activity excitant

An active activator, fly ash technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc. Restriction and other issues to achieve the effects of inhibiting alkali-aggregate reaction, enhancing seawater erosion ability, and improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

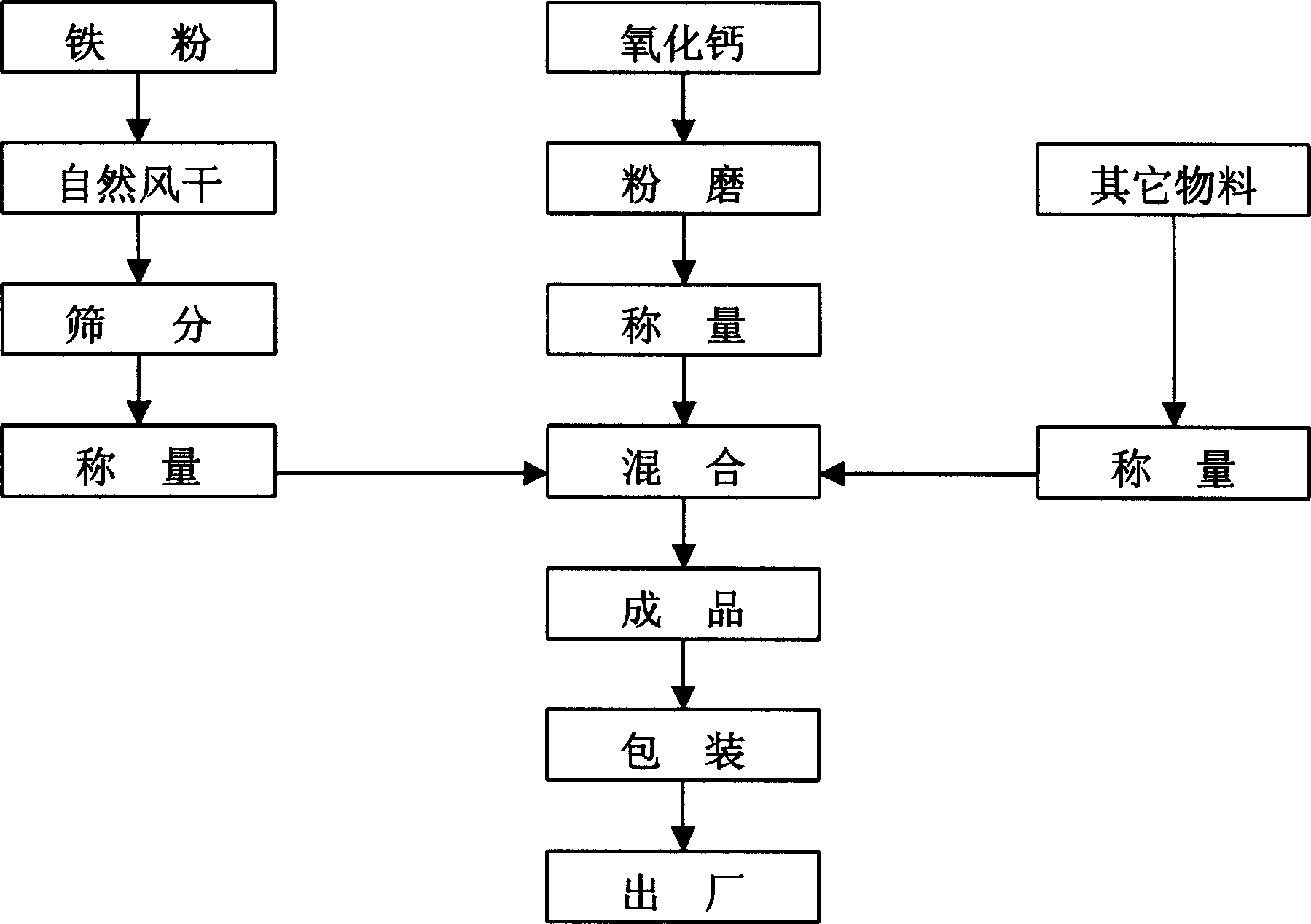

Method used

Image

Examples

Embodiment 1

[0007] Get iron powder 20%, calcium oxide 40%, thickening aid 5‰, fly ash 40%, above-mentioned share is weight ratio, and wherein thickening aid is general commercially available chemicals, and general chemical shop all has sale, Calcium oxide is a mineral raw material obtained after grinding. Dry the iron powder naturally, sieve it, weigh it according to the above weight ratio, grind the calcium oxide and weigh it according to the above weight ratio, and weigh the thickening aid and fly ash according to the above weight ratio, and mix them That is the finished product.

Embodiment 2

[0009] Take 50% of iron powder, 40% of calcium oxide, 5% of thickening aid, 10% of fly ash, and the others are the same as in Example 1.

Embodiment 3

[0011] Get 40% of iron powder, 20% of calcium oxide, 40% of fly ash, 5‰ of thickener, and others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com