Hybrid composite membrane based on polydopamine functionalized graphene and preparation and application

A technology of polydopamine and functionalization, applied in chemical instruments and methods, membrane technology, petroleum industry, etc., can solve the problems of reduced swelling resistance and defects, and achieve reduced swelling, low cost, and simple and controllable preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

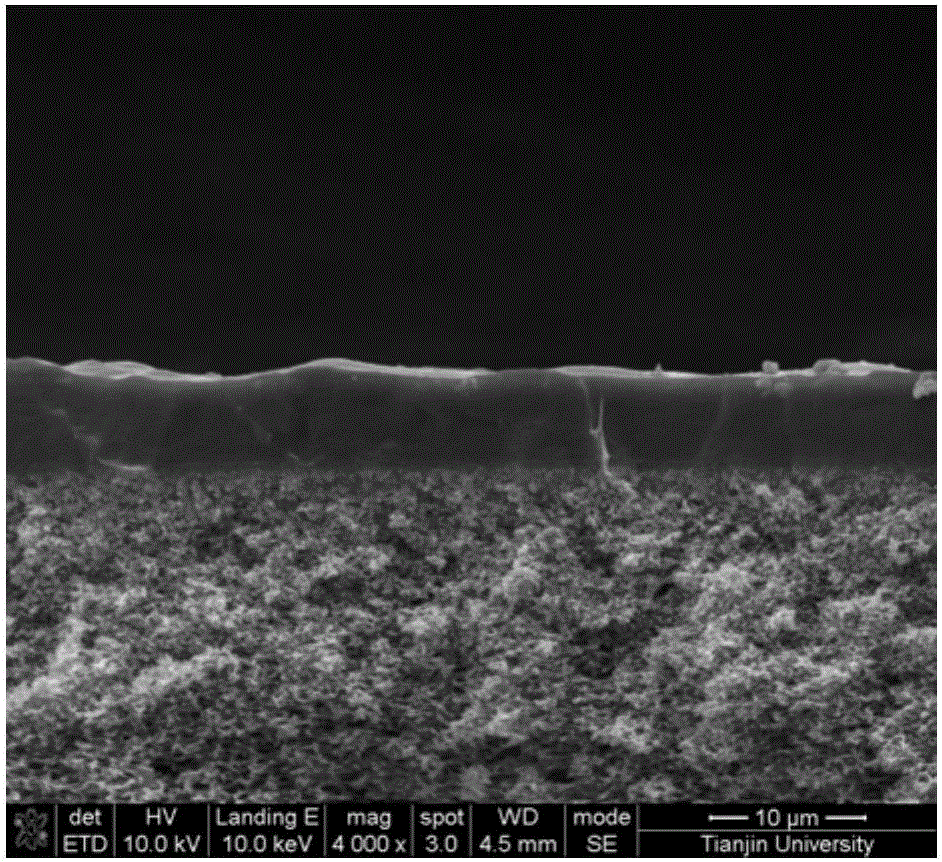

[0020] Embodiment 1: prepare the composite membrane of 2% of filling amount (being the mass ratio of graphene composition and matrix in filler), comprise the following steps:

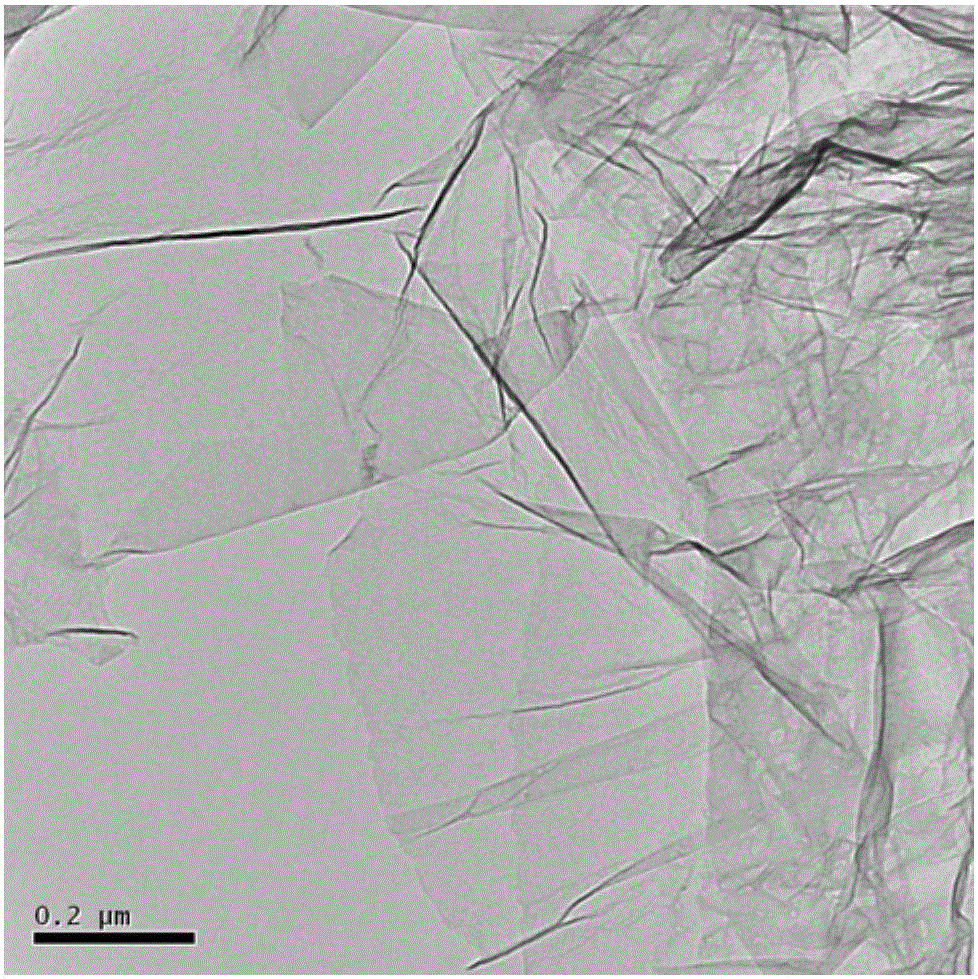

[0021] Step 1, preparation of functionalized graphene: disperse graphene oxide nanosheets in deionized water, the amount of graphene oxide used is determined according to the required ratio according to the quality of Pebax used in the subsequent steps, and the ratio is 2%. Become the suspension liquid of concentration 0.3g / L, ultrasonic dispersion 15min; Dissolve trometamol (trade name Trizma base) in deionized water and be made into the solution of 0.04mol / L; Said suspension liquid and solution equivolume Mix and adjust the pH of the mixture to 10 with hydrochloric acid. Add dopamine hydrochloride with the same mass as the aforementioned graphene oxide, and after dissolving, ultrasonically disperse for 15 minutes in an ice bath (the temperature is kept below 10°C); stir vigorously in a water bath preh...

Embodiment 2

[0025] Embodiment 2: prepare the composite film of filling amount 6%, comprise the following steps:

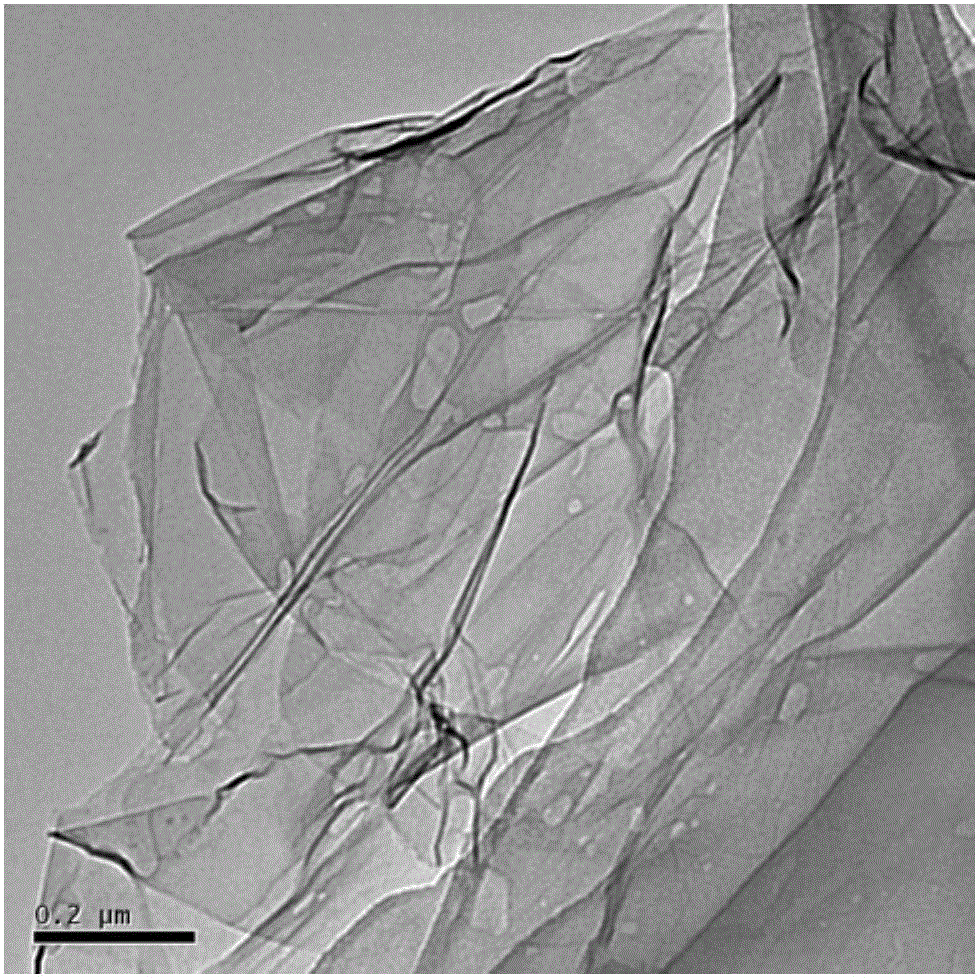

[0026]Step 1, preparation of functionalized graphene: disperse graphene oxide nanosheets in deionized water, the amount of graphene oxide used is determined according to the required ratio according to the quality of Pebax used in the subsequent steps, and the ratio is 6%. into a suspension with a concentration of 0.5g / L, and ultrasonically disperse for 10 minutes; dissolve Trizma base in deionized water to form a 0.02mol / L solution; mix the suspension with equal volumes of the solution, and dissolve The pH was adjusted to 8.5. Add dopamine hydrochloride with the same mass as the aforementioned graphene oxide, and after dissolving, ultrasonically disperse for 10 minutes in an ice bath (the temperature is kept below 10°C); stir vigorously in a water bath preheated to 60°C, and at a speed of 10000r / min Centrifuge under the conditions to obtain a precipitate, wash with deionized...

Embodiment 3

[0030] Embodiment 3: prepare the composite film of filling amount 8%, comprise the following steps:

[0031] Step 1, preparation of functionalized graphene: disperse graphene oxide nanosheets in deionized water, the amount of graphene oxide used is determined according to the required ratio according to the quality of Pebax used in the subsequent steps, and the ratio is 8%. into a suspension with a concentration of 0.6g / L, and ultrasonically dispersed for 30 minutes; Trizma base was dissolved in deionized water to form a 0.01mol / L solution; The pH was adjusted to 8. Add dopamine hydrochloride with the same mass as the aforementioned graphene oxide, and after dissolving, ultrasonically disperse for 30 minutes in an ice bath (the temperature is kept below 10°C); stir vigorously in a water bath preheated to 55°C, at a speed of 9500r / min Centrifuge under the conditions to obtain a precipitate, wash with deionized water and then with absolute ethanol, and dry under vacuum at 20°C;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com