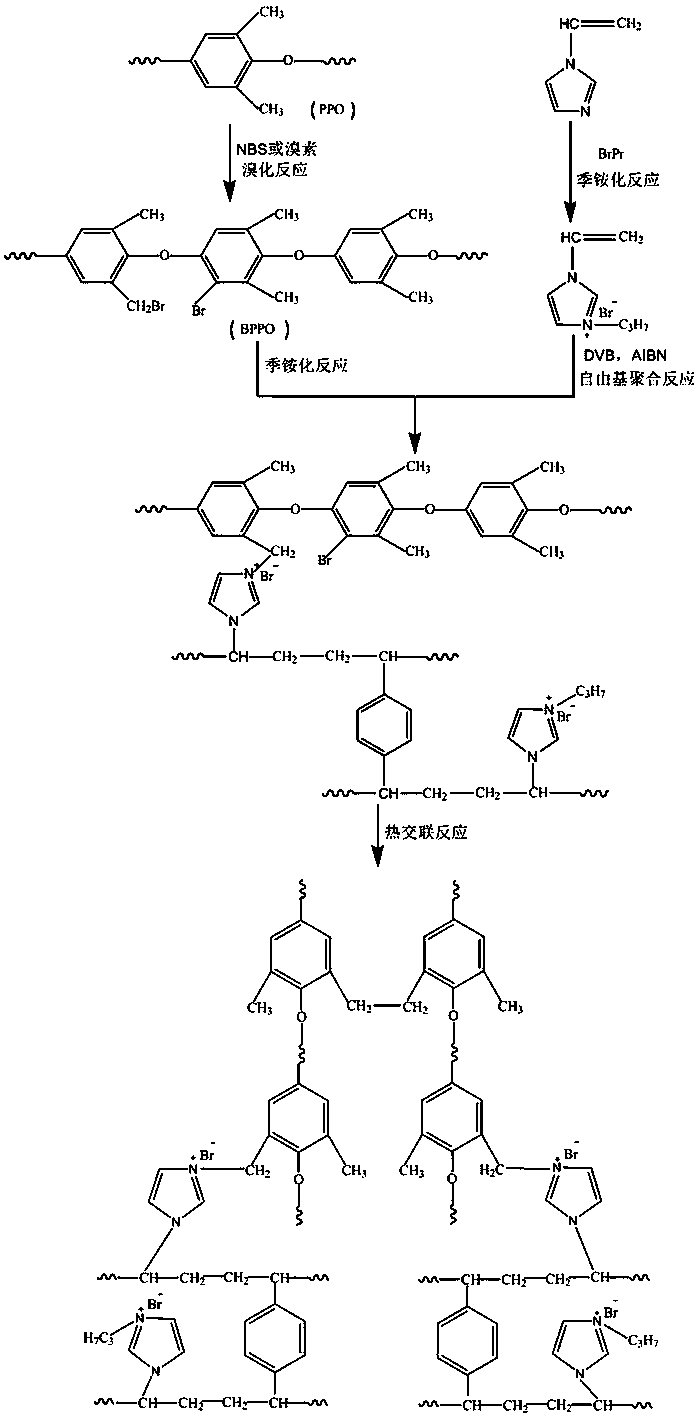

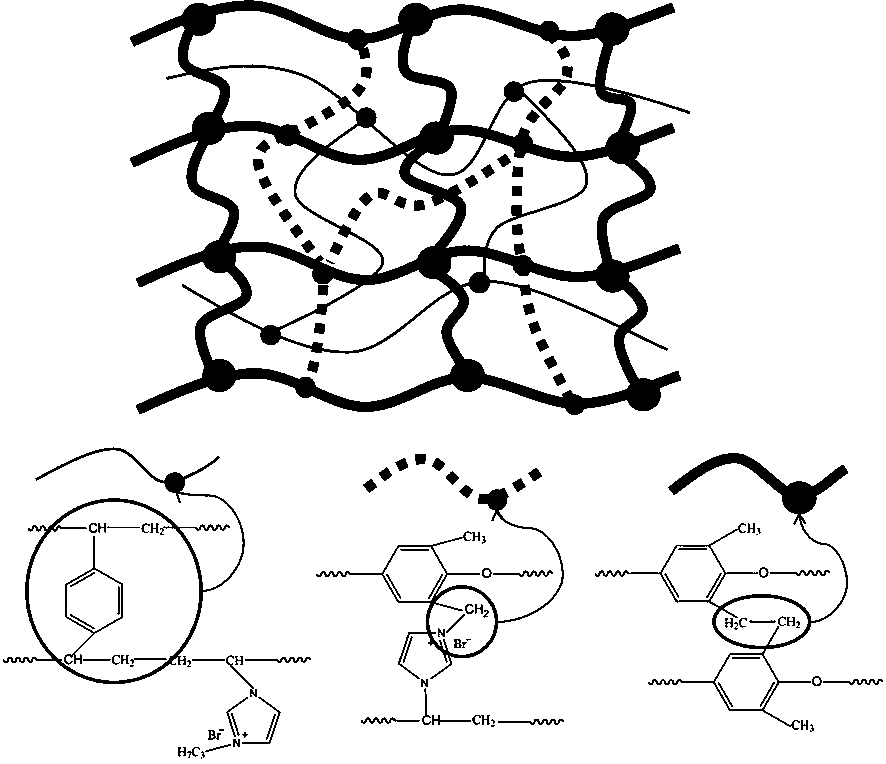

Method for preparing anion-exchange membrane with multi-crosslinked structure

An anion exchange membrane and multiple cross-linking technology, which is applied in the field of electrodialysis process, can solve the problems of complex control of trimethylamine membrane production process, influence on membrane mechanical strength and dimensional stability, increase membrane production process, etc., and improve anti-swelling performance , improve the service life, expand the effect of the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

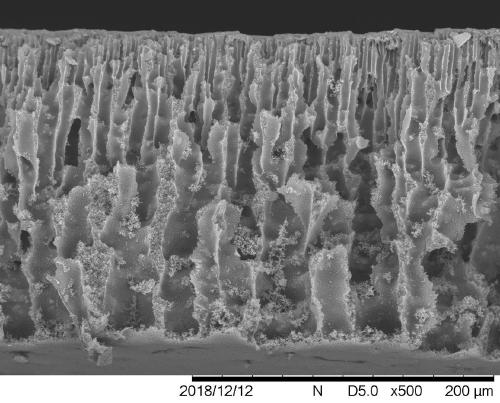

[0039] (1) Preparation of porous base membrane: Dissolve bromomethylated polyphenylene ether in N-methylpyrrolidone to form a casting solution with a mass content of 20% bromomethylated polyphenylene ether, scrape the casting solution on a flat plate After coating a thin layer with a thickness of 0.6-0.8 mm, immerse it in deionized water for 12 hours to solidify the casting solution to form a diaphragm, peel the diaphragm from the flat plate, and obtain a semi-finished porous base film. Drying at lower temperature for 12h obtains the porous base film;

[0040] (2) Preparation of monomer solution: In a 150ml clean beaker, add 19.96g of 1-vinylimidazole, 18.26g of bromopropane and 10.57g of isopropanol respectively, wherein the molar weight of bromopropane is 70% of that of 1-vinylimidazole , the mixed solution was fully stirred at 60°C for 48 hours to complete the quaternization reaction between 1-vinylimidazole and propane bromide; gN-methylpyrrolidone, fully stirred until az...

Embodiment 2

[0061] (1) Preparation of porous base membrane: bromomethylated polyphenylene ether and 50% polyethylene glycol 600 with the mass of bromomethylated polyphenylene ether were dissolved in N-methylpyrrolidone to form bromomethylated polyphenylene ether. The mass content of ether is 20% of the casting solution, the thickness of 0.11mm polyester mesh (equivalent aperture 0.15mm, opening rate 45%) is used as the supporting cloth, and a layer of 0.6-0.8mm thick casting film is coated on the supporting cloth. Membrane solution, and then immersed in deionized water for 12 hours to obtain a semi-finished porous base membrane, and dry the semi-finished porous base membrane at a temperature of 60°C for 12 hours to obtain a porous base membrane;

[0062] (2) Preparation of monomer solution: In a 150ml clean beaker, add 19.96g of 1-vinylimidazole, 18.26g of bromopropane and 10.57g of isopropanol respectively, wherein the molar weight of bromopropane is 70% of that of 1-vinylimidazole , the...

Embodiment 3

[0080] (1) Preparation of porous base membrane: bromomethylated polyphenylene ether and 20% lithium chloride with the mass of bromomethylated polyphenylene ether were dissolved in N-methylpyrrolidone to form bromomethylated polyphenylene ether Casting solution with a mass content of 20%, polyester mesh cloth with a thickness of 0.11mm (equivalent aperture 0.15mm, opening rate 45%) is used as a support cloth, and a layer of casting solution with a thickness of 0.6-0.8mm is coated on the support cloth , and then immersed in deionized water for 12 hours to obtain a semi-finished porous base film, and dry the semi-finished porous base film at 60°C for 12 hours to obtain a porous base film;

[0081] (2) Preparation of monomer solution: In a 150ml clean beaker, add 19.96g of 1-vinylimidazole, 18.26g of bromopropane and 10.57g of isopropanol respectively, wherein the molar weight of bromopropane is 70% of that of 1-vinylimidazole , the mixed solution was fully stirred at 60°C for 48 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com