Cellulose microsphere as well as preparation method and use thereof

A technology of cellulose microspheres and cellulose solutions, which is applied in the field of polymer chemistry, can solve the problems of a large amount of waste liquid, waste gas and waste, cellulose beads pollution, and limited applications, and achieve good mechanical properties, good flow properties, Versatile Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

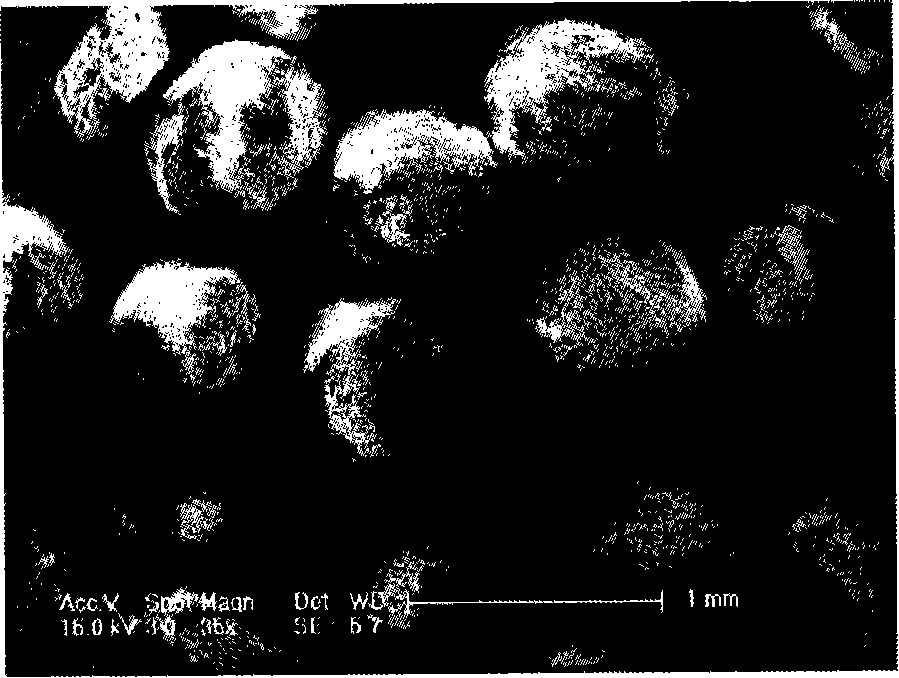

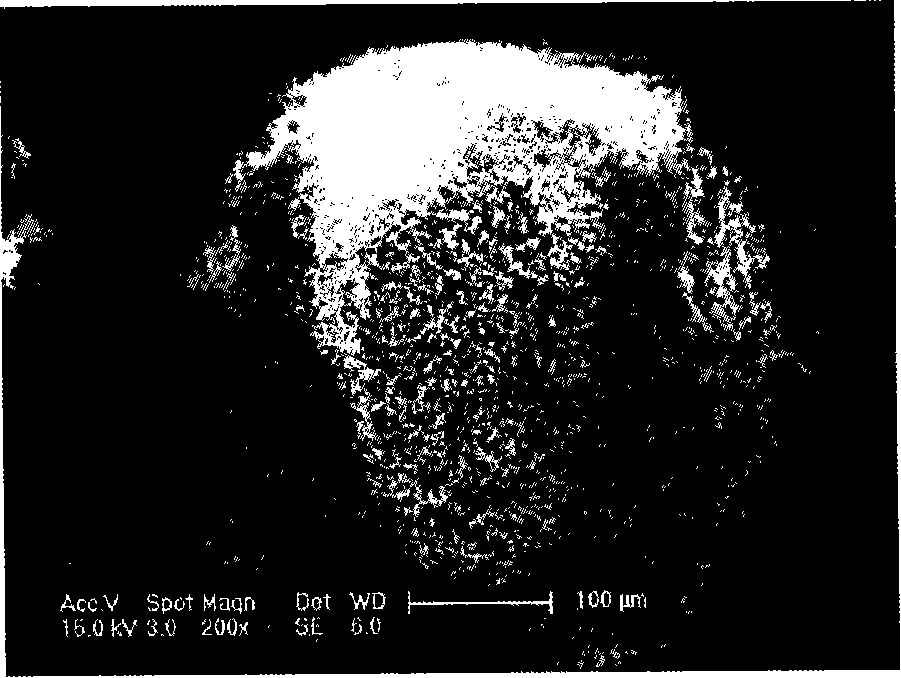

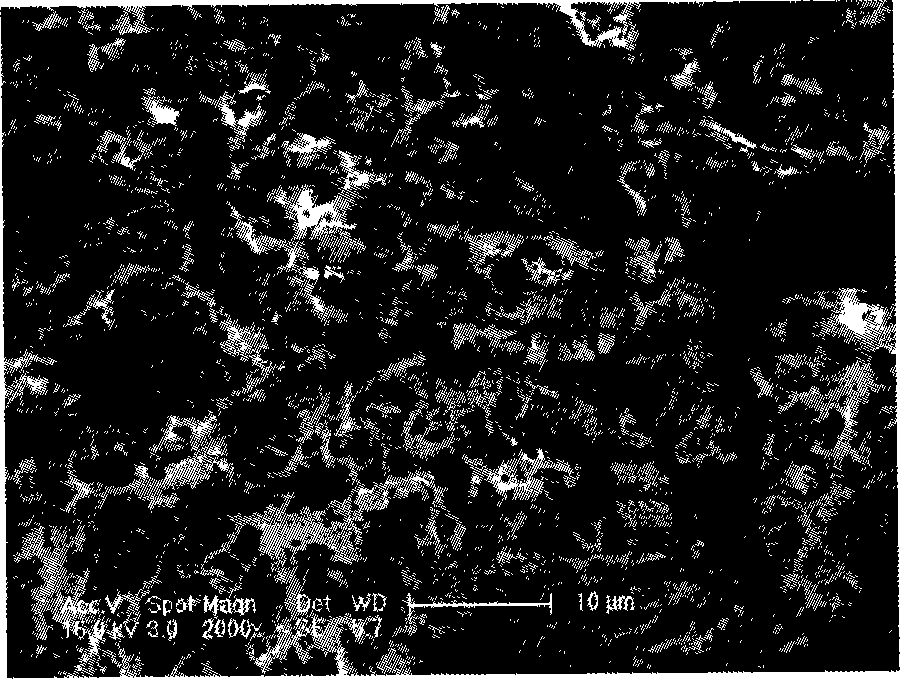

Embodiment 1

[0018] Pre-cool NaOH / urea aqueous solution to -12°C as solvent to dissolve cellulose to prepare cellulose solution, add 300ml kerosene and transformer oil mixed solvent, and 3ml Twin-80 / Span -80 composite emulsifier, after stirring evenly, slowly add 100ml of the above-prepared cellulose solution, complete the addition within 60min, control the stirring speed to 200r / min, and emulsify at room temperature for 30min. Keep the same conditions and continue to pre-cure for 1 hr, then add dilute acid to acidify the pH to neutral to regenerate the cellulose. Stirring was stopped, and the layers were left to stand, the upper layer was an organic solvent, the lower layer was an aqueous phase, and the cellulose particles were precipitated in the lower layer. Pour out the upper organic phase, which can be directly recycled, remove the water phase, decant and wash the cellulose particles with distilled water for several times, soak and wash with 10% ethanol aqueous solution for 3 to 5 tim...

Embodiment 2

[0021] Pre-cool NaOH / urea aqueous solution to -12°C as a solvent to dissolve cellulose to prepare a cellulose solution. Add 300ml of liquid paraffin and 9ml of Span-80 into a 500ml three-neck flask equipped with a condensation reflux device and a constant temperature water bath. After stirring evenly, slowly add Add 50ml of the above-prepared cellulose solution within 30 minutes, control the stirring speed to 800r / min, and emulsify at room temperature for 30 minutes. Keep the same conditions and continue to pre-cure for 1 hr, then add 10% hydrochloric acid dropwise to acidify to neutral pH to regenerate the cellulose. Stirring was stopped, and the layers were left to stand, the upper layer was an organic solvent, the lower layer was an aqueous phase, and the cellulose particles were precipitated in the lower layer. Pour out the upper organic phase, which can be directly recycled, remove the water phase, decant and wash the cellulose particles with distilled water for several t...

Embodiment 3

[0024] Pre-cool NaOH / urea aqueous solution to -12°C as solvent to dissolve cellulose to prepare cellulose solution, add 300ml200 # Liquid paraffin, 30ml of Span-80 and potassium oleate compound emulsifier, after stirring evenly, slowly add 30ml of the above-prepared cellulose solution, complete the addition within 15min, control the stirring speed to 1000r / min, and emulsify at room temperature for 30min. Keep the same conditions and continue to pre-cure for 4 hours, then add 10% dilute acidification dropwise until the pH is neutral to regenerate the cellulose. Stirring was stopped, and the layers were left to stand, the upper layer was an organic solvent, the lower layer was an aqueous phase, and the cellulose particles were precipitated in the lower layer. Pour out the upper organic phase, which can be directly recycled, remove the water phase, decant and wash the cellulose particles with distilled water for several times, soak and wash with 10% ethanol aqueous solution for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com