Nucleic acid aptamer functionalized POSS (polyhedral oligomeric silsesquioxane) crosslinking organic-silica gel hybridization monolithic column, and preparation method thereof

A nucleic acid aptamer and silica hybrid technology, applied in the field of analytical chemistry, can solve the problem of incompatibility between the POSS hydrophobic cross-linking agent and the aptamer aqueous solution, and achieve a uniform and stable reaction system, good swelling resistance, and a site of action. many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a nucleic acid aptamer functionalized POSS cross-linked organic-silica hybrid monolithic column, the specific steps are:

[0026] (1) Centrifuge the thiol-modified aptamer at 8000r / min for 5 minutes, then add water to dilute to 1000 μmol / L, heat at 90°C for 3 minutes, and cool to room temperature to form the aptamer stock solution 1;

[0027] (2) According to the mass ratio of 12.5:3.75:83.75, accurately weigh 2-acrylamide-2-methylpropanesulfonic acid monomer, methacrylate grafted polyhedral oligomeric silsesquioxane, ethyl Diol dimethacrylate is added to the centrifuge tube, the amount of accurately added initiator accounts for 1.0wt% of the total amount of monomer and crosslinking agent, and then the porogen is PEG 10000 in proportion to the total amount of porogen composition 4.3% of the porogen, and water accounted for 0.5% (column 1), 2.5% (column 2), 5.0% (column 3), 5.5% (column 4) of the total porogen composition, corresponding to N,N-dim...

Embodiment 2

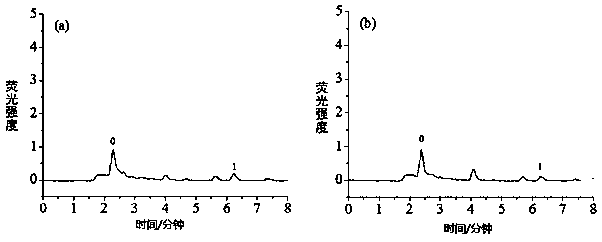

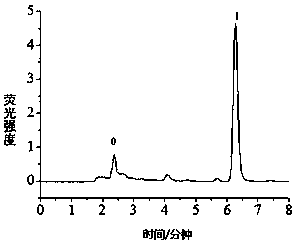

[0031]Apply the blank column, control column and nucleic acid aptamer affinity column (column 3 as an example), the length of the affinity column is 10cm, and implement according to the following steps: (1) Equilibration: equilibrate with binding buffer for 0.5 hours first, and the chromatographic conditions are Flow rate 0.10 mL / min, pressure 250psi, described binding buffer is 10mmol / L Tris-HCl, 120 mmol / L NaCl, 5 mmol / L KCl and 20mmol / LCaCl 2 , pH 8.50; (2) Enrichment: Inject 20 μL of 10 ng / mL ochratoxin A solution separately, enrich on the monolithic column for 1 hour, the chromatographic conditions are 0.02 mL / min, pressure 250psi; (3) Cleaning: Install the enrichment column on the liquid chromatography pump, and wash the blank column, control column and nucleic acid aptamer affinity monolithic column with binding buffer respectively; the washing conditions are as follows: flow rate 0.1 mL / min, pressure 500 psi, collect the final washing (4) Elution: Use 30% ACN: 70% TE b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com