A doped basic cobalt carbonate/cobalt carbonate composite precursor and its preparation method and application

A technology of cobalt carbonate and doping, which is applied in the direction of cobalt carbonate, cobalt compounds, chemical instruments and methods, etc., to achieve high tap density, appropriate particle size increase, and uniform and stable reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

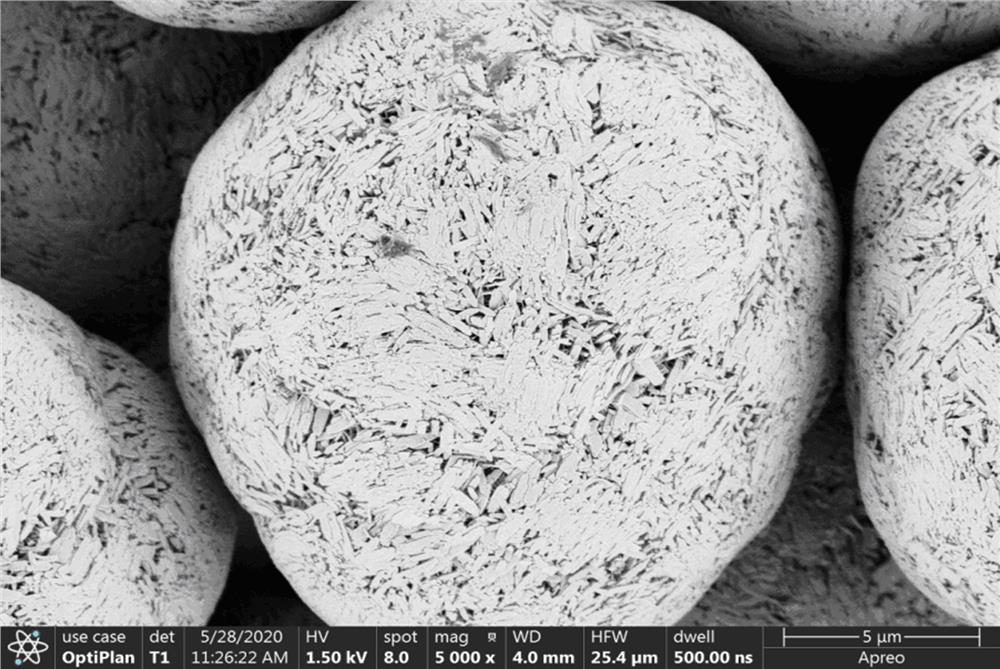

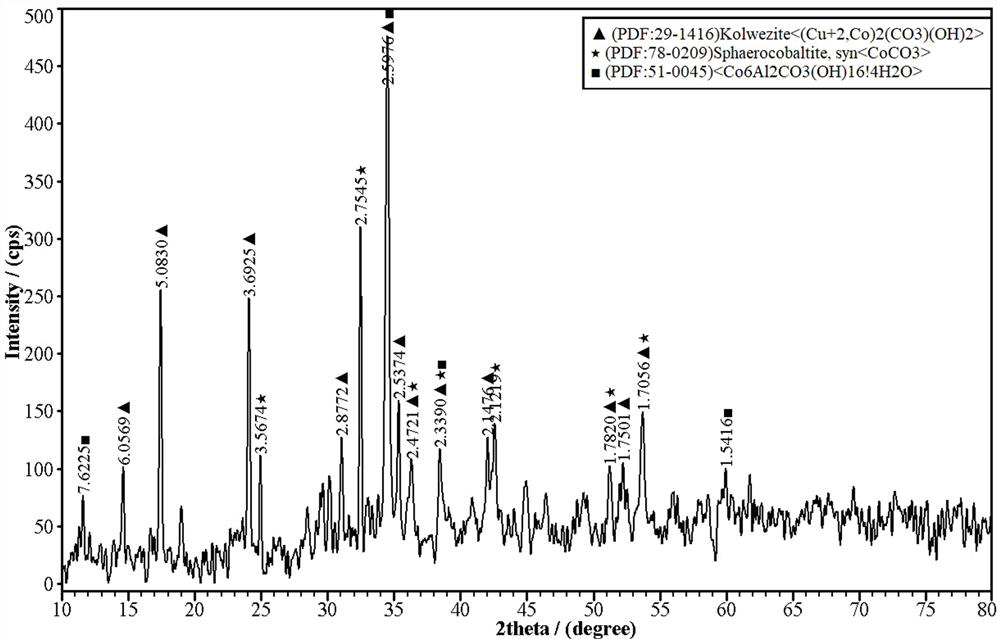

Image

Examples

Embodiment 1

[0031] This embodiment includes the following steps:

[0032] Step S1, using cobalt sulfate as the cobalt source and aluminum sulfate as the aluminum source, prepare a cobalt-aluminum mixed salt solution, wherein the cobalt metal concentration is 1.5mol / L, and the aluminum metal concentration is 0.03mol / L; prepare 2mol / L bicarbonate ammonium solution;

[0033] Step S2, in the 50L reactor, add a certain amount of 1.5mol / L ammonium bicarbonate solution as the base liquid, make the liquid level just below the bottom of the stirring paddle, start stirring, and the stirring line speed is 3 m / s, The reaction temperature of the control system was 45°C. Add the mixed salt solution and ammonium bicarbonate solution prepared in step S1 into the system in parallel, wherein the feed rate of the mixed salt solution is 2.5 L / h, and the ammonium bicarbonate solution feeding control system reaction pH is 7.40~7.50. When the particle size D50 is 10um, the line speed decreases by 0.2 m / s ever...

Embodiment 2

[0036] This embodiment includes the following steps:

[0037] Step S1, using cobalt sulfate as the cobalt source and aluminum sulfate as the aluminum source, prepare a cobalt-aluminum mixed salt solution, wherein the cobalt metal concentration is 1.8mol / L, and the aluminum metal concentration is 0.04mol / L; prepare 3mol / L ammonium bicarbonate solution;

[0038] Step S2, in the 50L reaction kettle, add a certain amount of 1.5mol / L ammonium bicarbonate solution as the base liquid, make the liquid level just below the bottom of the stirring paddle, start stirring, and the stirring line speed is 3.5 m / s, control The reaction temperature of the system is 50°C. Add the mixed salt solution and ammonium bicarbonate solution prepared in step S1 into the system in parallel, wherein the feed rate of the mixed salt solution is 3 L / h, and the ammonium bicarbonate solution feeding control system reaction pH value is 7.30~7.40. When the particle size D50 is 10um, the line speed decreases by...

Embodiment 3

[0041] This embodiment includes the following steps:

[0042] Step S1, using cobalt chloride as the cobalt source and aluminum chloride as the aluminum source, prepare a cobalt-aluminum mixed salt solution, wherein the cobalt metal concentration is 1.8mol / L, and the aluminum metal concentration is 0.05mol / L; prepare 2.5mol / L ammonium bicarbonate solution;

[0043] Step S2, in the 50L reaction kettle, add a certain amount of 1.0mol / L ammonium bicarbonate solution as the base liquid, make the liquid level just below the bottom of the stirring paddle, start stirring, and the stirring line speed is 3.5m / s, The reaction temperature of the control system was 55°C. Add the mixed salt solution and ammonium bicarbonate solution prepared in step S1 into the system in parallel, wherein the feed rate of the mixed salt solution is 3.5 L / h, and the ammonium bicarbonate solution feeding control system reaction pH value is 7.20~7.30. When the particle size D50 is 10um, the line speed decrea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com